As woodworking machinery evolves toward higher automation and intelligence, electrical stability and safety have become central concerns for manufacturers. CNC routers, panel saws, edge banders, and automated production lines rely on increasingly complex control systems. While attention is often focused on motors, spindles, and software, one critical component is frequently overlooked: the control transformer.

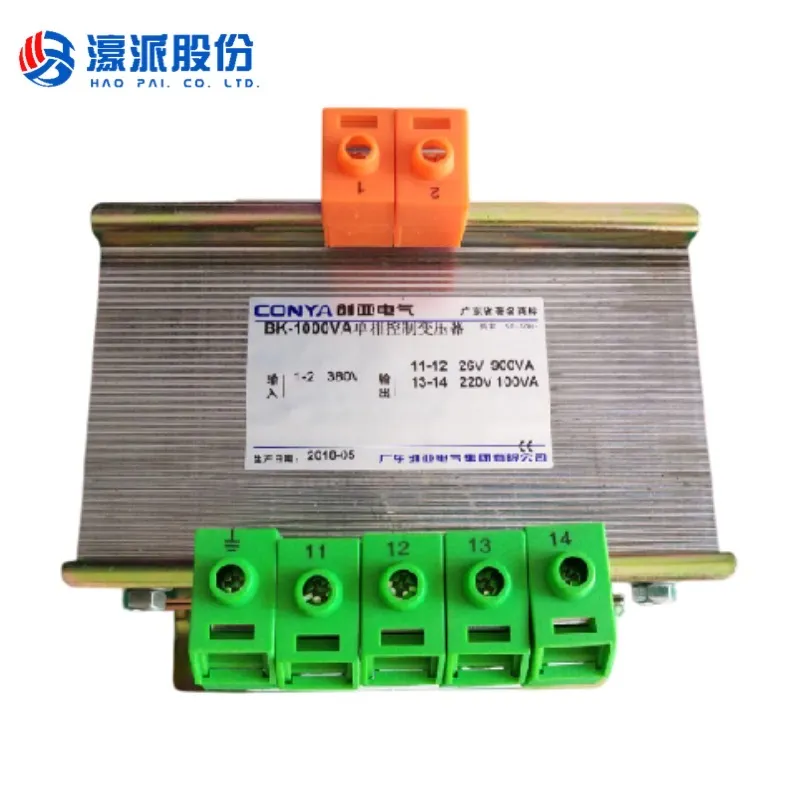

In modern workshops, the Single-Phase Control Transformer is no longer a simple voltage-conversion device. It has become a foundational element for improving machine safety, stabilizing control circuits, and enhancing overall operating efficiency. Foshan Haopai Mechanical and Electrical Equipment Co., Ltd., drawing on more than a decade of technical evolution, is positioning this component as a key entry point for intelligent electrical upgrades in woodworking machinery.

Why Electrical Control Has Become a Bottleneck in Woodworking Equipment

Increasing Control System Complexity

Modern CNC woodworking machines integrate PLCs, servo drives, sensors, and HMI panels. These systems require stable, isolated, and accurately regulated power. Inadequate control power can lead to signal interference, false alarms, or unexpected shutdowns. This is why high-quality Woodworking Electrical Parts are now critical to machine reliability.

Safety Risks from Unstable Voltage

Voltage fluctuations, electrical noise, and poor grounding can directly impact operator safety. Without proper isolation, control circuits may be exposed to high-voltage surges from motors or spindles. A well-designed Motor Control Transformer plays a vital role in protecting both personnel and sensitive electronics.

Energy Efficiency Pressure

Manufacturers are under growing pressure to reduce energy loss and improve operational efficiency. Electrical components that minimize heat generation and power waste contribute directly to lower operating costs, making the Wood Machine Transformer a strategic upgrade rather than a passive component.

The Role of Single-Phase Control Transformers in Smart Upgrades

A Single-Phase Control Transformer provides electrical isolation, voltage regulation, and stable power delivery for control circuits. In woodworking machinery, it typically supplies power to PLCs, relays, sensors, solenoid valves, and safety modules.

Enhanced Electrical Isolation

Isolation between primary and secondary circuits reduces the risk of electrical shock and prevents high-voltage interference from reaching control systems. This is essential for CNC machines that combine high-power drives with delicate logic control, especially when paired with a CNC Power Supply Transformer.

Stable and Precise Voltage Output

Control systems require consistent voltage to operate correctly. Fluctuations can cause relay chatter, PLC errors, or communication failures. A properly specified Motor Control Transformer ensures consistent voltage under varying load conditions.

Reduced Downtime and Maintenance

By stabilizing control circuits, the transformer helps reduce fault frequency and extends the lifespan of other Woodworking Electrical Parts, contributing to higher machine availability.

Performance Comparison: With and Without Control Transformer Upgrade

| Indicator | Conventional Power Setup | Optimized Control Transformer System | Improvement |

| Control Voltage Stability | Moderate fluctuation | Highly stable via Single-Phase Control Transformer | Significant |

| Electrical Isolation Level | Limited | Full isolation with Wood Machine Transformer | High |

| Control System Failure Rate | Occasional | Reduced by 30–45% | Strong improvement |

| Heat Generation | Higher | Lower with CNC Power Supply Transformer | Energy saving |

| Operator Safety Risk | Medium | Lower with Motor Control Transformer | Enhanced safety |

This comparison shows that upgrading control transformers has a measurable impact on both safety and efficiency.

Key Application Scenarios in Woodworking Machinery

CNC Routing and Drilling Centers

Complex CNC systems benefit from a dedicated CNC Power Supply Transformer that ensures stable logic control independent of spindle load fluctuations.

Edge Banding and Panel Processing Lines

In continuous-operation environments, reliable Woodworking Electrical Parts reduce unexpected stoppages and ensure consistent product quality.

Motor Control Cabinets

Servo motors, contactors, and frequency converters require clean control power. A properly sized Motor Control Transformer protects these systems from voltage spikes.

Retrofitting and Intelligent Upgrades

When older machines are upgraded with automation modules, replacing or adding a Wood Machine Transformer is often the most cost-effective way to improve reliability.

Haopai’s Engineering Advantage

As a National High-Tech Enterprise, Foshan Haopai Mechanical and Electrical Equipment Co., Ltd. integrates design, assembly, testing, and on-site commissioning capabilities. From equipment upgrading and non-standard automation to intelligent production line planning, Haopai understands how control transformers interact with the broader electrical ecosystem of woodworking machines.

Each Single-Phase Control Transformer is selected or customized based on real load conditions, environmental factors, and long-term reliability requirements—ensuring compatibility with modern Woodworking Electrical Parts and control architectures.

FAQ: Common Questions from Manufacturers

Q1: Is a single-phase control transformer suitable for CNC machines?

Yes. Most control circuits in CNC machines rely on single-phase power supplied by a CNC Power Supply Transformer.

Q2: Does adding a transformer increase energy consumption?

No. A properly designed Single-Phase Control Transformer improves efficiency by reducing losses caused by unstable voltage.

Q3: Can transformers be customized for different machines?

Absolutely. Haopai provides customized Motor Control Transformer solutions based on machine configuration.

Q4: How does a control transformer improve safety?

It isolates control circuits from high-voltage sources, reducing shock risk and system damage—an essential function of a Wood Machine Transformer.

Q5: Is transformer upgrade suitable for older machines?

Yes. Retrofitting with modern Woodworking Electrical Parts is a common and effective upgrade path.

Conclusion: Small Component, Big Impact

In the push toward smarter, safer, and more efficient woodworking machinery, attention to electrical fundamentals is essential. The Single-Phase Control Transformer may appear modest, but its impact on system stability, operator safety, and long-term efficiency is profound. When integrated correctly with other Woodworking Electrical Parts, it becomes a cornerstone of intelligent machine design.

Backed by strong R&D capabilities and extensive field experience, Foshan Haopai Mechanical and Electrical Equipment Co., Ltd. continues to help manufacturers unlock hidden performance potential through practical, engineering-driven solutions.

Call to Action

If you are planning to upgrade your woodworking machinery, improve electrical safety, or stabilize CNC control systems, consider starting with the right control transformer.

Contact Foshan Haopai Mechanical and Electrical Equipment Co., Ltd. to explore how a properly engineered CNC Power Supply Transformer or Motor Control Transformer can elevate your production line.