On July 10, 2025, we warmly congratulate Punas (Foshan) Co., Ltd. on officially joining the Haopai Specialized and Innovative Customer Center. The cooperation between Punas and Haopai is essentially a technological coupling of "precision handling" and "intelligent technological transformation". Through product

complementarity, service collaboration, and ecological sharing, we aim to build a complete closed loop for the automation upgrade of the woodworking machine industry. Under the fading of labor dividends and the wave of customization, this cooperation model is expected to become a benchmark in the industry, helping China's woodworking machine move from "scale expansion" to "value cultivation".

Technical Collaboration: Deep Integration of Vacuum Handling and Non standard Technological Transformation

1. The core technological advantages of Panas

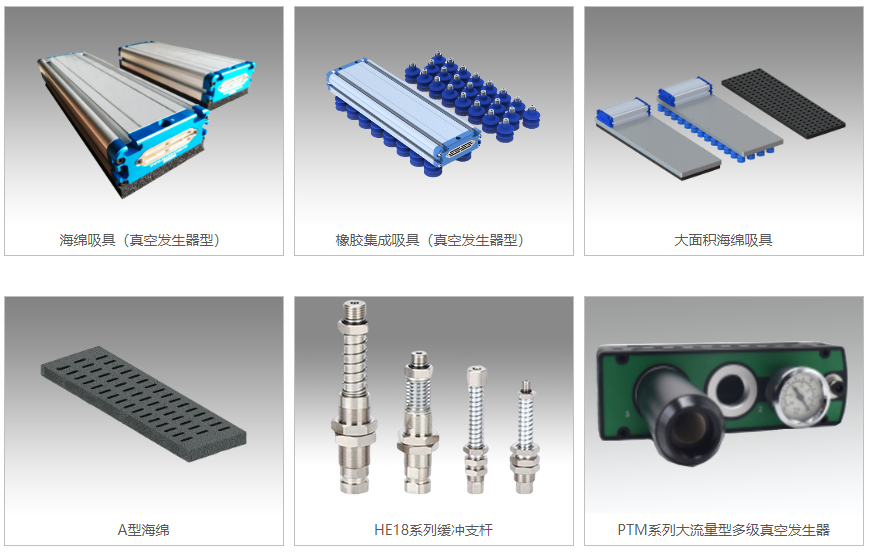

Punas is deeply engaged in the research and development of vacuum handling systems, with products including vacuum suction tools, sponge suction cups, and robotic end pickers, perfectly adapted to the woodworking industry's board handling and palletizing scenarios. What is particularly outstanding is its customization ability, which can tailor scratch resistant and highly absorbent handling solutions based on the characteristics, size, and craftsmanship of the wood.

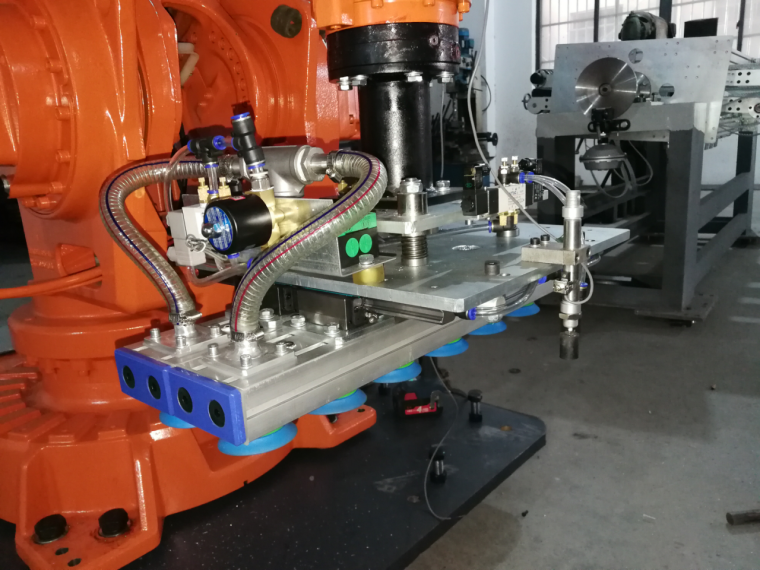

Panas robotic arm end effector

2. Haopai's non-standard technological transformation strength

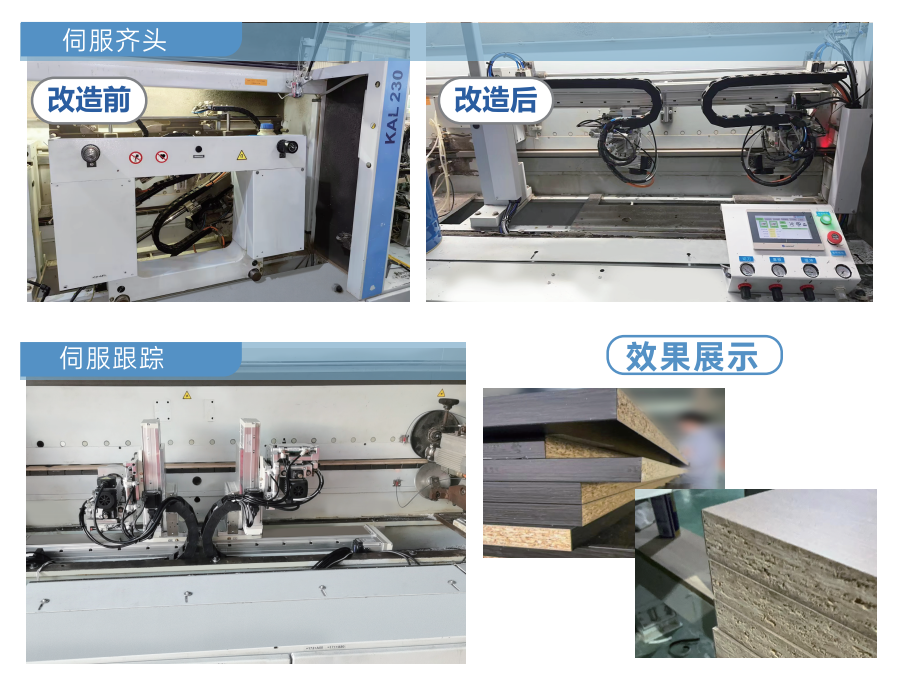

Haopai has core technologies such as laser modification, PUR glue machine upgrade, and servo alignment modification, which can improve the accuracy and efficiency of woodworking equipment. Accumulatively completed over 100000 equipment upgrade projects, covering mainstream woodworking machine such as edge banding machines and electronic saws, with industry-leading technological maturity.

Laser Transformation-Haopai

Servo head alignment+servo tracking effect display-Haopai Panas' vacuum handling system can seamlessly integrate with the high-precision equipment modified by Haopai, achieving full process automation from sheet loading, procssing to unloading.

Case Study of Robot Loading and Unloading Project - Haopai

Product complementarity: Full chain coverage from accessories to the entire line

1. Ecological advantages of Haopai's accessories

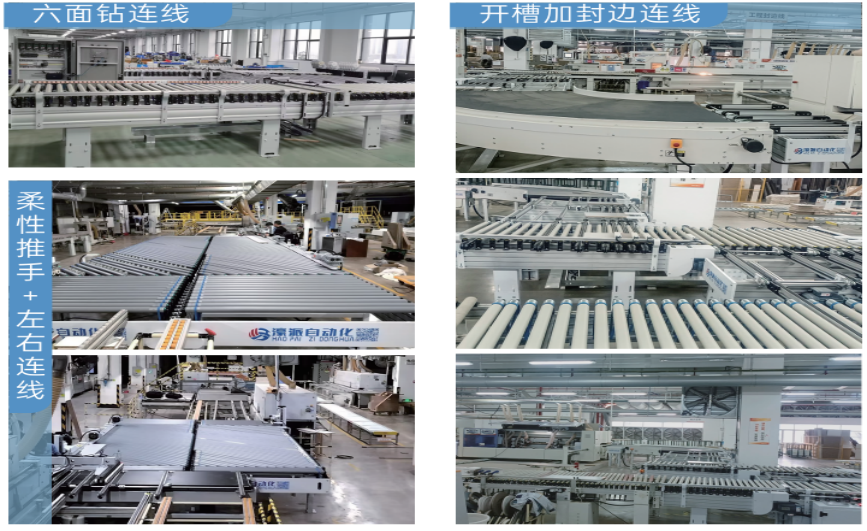

Accumulated over 200000 non-standard accessory categories, covering edge banding machine accessories, paint line accessories, etc., can quickly respond to the spare parts needs of woodworking enterprises. Independently develop intelligent factory information management systems (such as energy management and data collection) to assist enterprises in achieving digital production.

OPPEIN Six sided Diamond Connection+Slot Connection+Flexible Push Hands Case Study

2. Panas' handling solution

To address the pain points of heavy object handling in the woodworking industry, we provide special accessories such as anti-static sponge suction tools and high-temperature resistant rubber suction cups, which are suitable for different process environments. The robotic arm end effector can be integrated into the Haopai automation connection equipment to achieve seamless cross process connection.

Panas robotic arm end effector

One stop procurement: Customers do not need to connect with multiple suppliers. Haopai can work with Panas to provide a complete line solution of

"equipment+accessories+handling system", reduce procurement costs.Service collaboration: Both parties share a nationwide service network (consisting of a team of nearly 200 people from Haopai and a regional service provider from Punas), achieving a rapid response time of 48 hours.Market resonance:Collaborative expansion of specialized, refined, and innovative ecosystems

1. The industry status of Haopai

Serving over 10000 enterprises, covering multiple fields such as home furnishings, ceramics, and new energy, with the home furnishings industry accounting for over 60%, deeply binding with top customers such as Sofia and OPPEIN.

2. Punas' differentiated positioning

Focusing on the sub field of vacuum handling, our customers mainly consist of high-precision demand enterprises (such as customized furniture and precision woodworking), forming a complementary relationship with Haopai's customer base.Haopai's products include:Cutting Equipment Parts、General Woodworking Electrical Parts、Edgebander Machine Parts、CNC Series Parts、General Woodworking Components Parts.

In the critical period of economic transformation and innovation driven development, specialized and innovative customer centers have become a key force in promoting high-quality development of small and medium-sized enterprises. By integrating resources such as technology, talent, and funding, and building a shared platform, enterprises can obtain key elements at low cost and improve innovation efficiency. Our professional service team covers the entire life cycle of enterprises, from entrepreneurial planning to market expansion, providing one-stop solutions, and also promoting the transformation of achievements through collaboration between midwifery, academia, and research. Focusing on specific industries to form clusters, promoting collaborative cooperation among enterprises, reducing costs, enhancing competitiveness, and expanding markets through activities. Create an open and inclusive innovation culture, stimulate the vitality of enterprise innovation, establish a fault-tolerant mechanism to encourage bold experimentation. In addition, establishing channels for talent introduction and addressing concerns about talent retention. The specialized and innovative customer center is fully empowering enterprises, driving industrial upgrading, and injecting strong momentum into high-quality economic development.