In the world of high-end custom furniture, architectural woodcraft, and precision interior manufacturing, efficiency is no longer measured only by spindle speed or feed rate—it is measured by how many complete operations can be executed in a single setup. As demand grows for complex designs, curved surfaces, fine details, and zero-defect precision, the traditional woodworking CNC setup—often dependent on multiple tools, multiple spindles, or even multiple machines—struggles to keep pace.

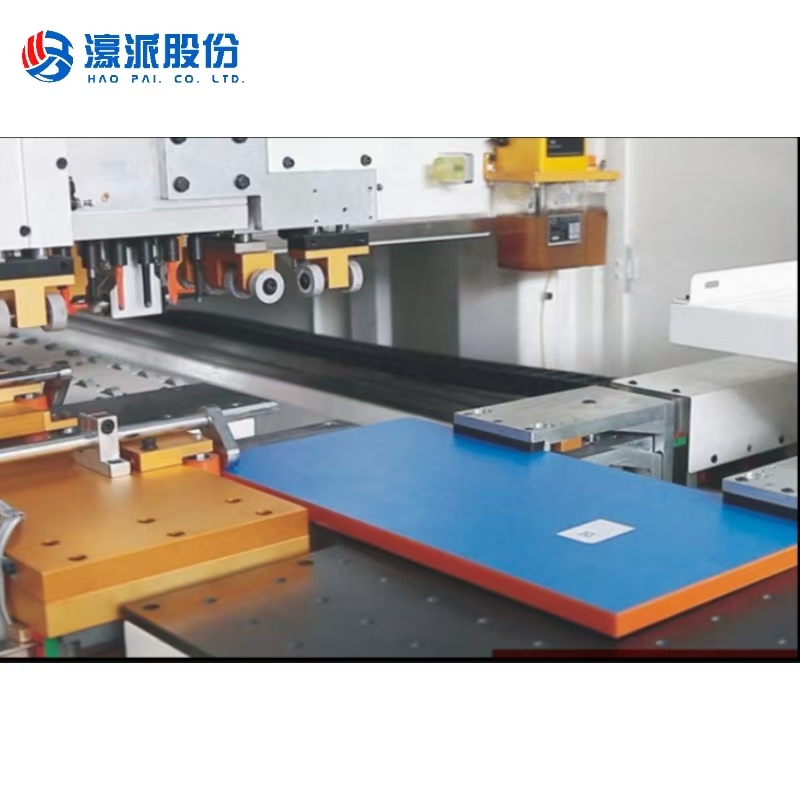

Foshan Haopai Mechanical and Electrical Equipment Co., Ltd., a company that has transformed over the past decade into an industry-leading high-tech enterprise, is now pushing CNC boundaries with the 8-in-1 CNC Woodworking Head. Backed by independent R&D capabilities, advanced machining workshops, and a strong technical team, Haopai is positioning its newest innovation as a breakthrough that challenges long-held assumptions about CNC machining limits. At its core is a simple but powerful promise: one clamping, all processes completed.

1. Deep Dive Into the Pain Points of Modern Woodworking Manufacturing

Accumulated Error from Multi-Stage Processes

When a workpiece must be moved from drilling to milling to boring and then to slotting or engraving, every repositioning introduces deviation. Even a fraction of a millimeter adds up, especially with curved panels or complex three-dimensional contours. Traditional heads and spindles cannot eliminate this cumulative error, leading to tolerances slipping beyond acceptable limits.

Time Lost to Frequent Tool Changes and Re-zeroing

Switching between tools for drilling, milling, routing, and chamfering can consume 20–40% of total machining time. Even automated systems struggle when too many separate heads or spindles are involved. Operators also face constant re-positioning tasks, making productivity unpredictable.

Precision Difficulties With Irregular or Artistic Wood Components

Carved furniture components, decorative door panels, structural wood elements, and irregular-profile parts demand more than a basic spindle upgrade. They require a CNC Compound Processing Head capable of shifting instantly between functions while maintaining a stable positioning accuracy across operations.

2. Breakthrough Technologies Behind the New Era of CNC Innovation

Haopai’s engineering team has condensed eight major woodworking processes into a single integrated architecture—embodied in the groundbreaking Protean Milling Drilling Head.

Eight-Function Integrated Design

Within the Multi-function CNC Spindle, milling, drilling, boring, slotting, chamfering, carving, edge trimming, and special-shape processing coexist without mechanical conflict. This eliminates the historical need for multi-machine involvement.

Ultra-Fast Automatic Tool Change (<2 seconds)

A newly developed servo-driven shifting mechanism allows the 8-in-1 CNC Woodworking Head to switch tools in under two seconds, minimizing downtime and enabling continuous, uninterrupted machining workflows.

High-Precision Spindle Positioning (±0.01mm Repeatability)

The precision-locking mechanism guarantees stable tool orientation and perfect repeatability. Even under heavy loads or long processing cycles, the Woodworking Boring Milling Head maintains a repeat positioning accuracy of ±0.01mm—critical for expensive materials and intricate components.

3. Performance Gains Backed by Quantitative Data

The results of Haopai’s tests across various application scenarios demonstrate remarkable efficiency improvements.

CNC Processing Performance Comparison Table

| Category | Traditional Single-Function Head | Haopai 8-Function Protean System | Improvement |

| Total Processing Time per Complex Panel | 45–60 min | 22–30 min using the CNC Compound Processing Head | 45–55% faster |

| Tool Change Frequency | 5–12 times | Near zero with Multi-function CNC Spindle | 100% eliminated |

| Positioning Error Accumulation | 0.1–0.25 mm | ≤0.02 mm with high-precision system | 80–90% reduction |

| Waste Material Rate | 6–9% | 2–3% using Woodworking Boring Milling Head | Up to 65% reduction |

| Machining Stability | Medium fluctuation | High-stability 8-in-1 CNC Woodworking Head | Significant improvement |

These numbers highlight an undeniable shift: the combination of integrated design and ultra-high precision produces not incremental gains, but a full-scale leap in CNC capability.

4. Real-World Applications: Transforming How Manufacturers Work

High-End Custom Cabinet Door Production

Raised panels, relief carvings, decorative frames, and detailed edge features can be produced in a single mounting using the Protean Milling Drilling Head, eliminating re-clamping errors and boosting consistency.

Complex Carved Furniture Components

Chair legs, armrests, decorative trims, lattice patterns, and artistic moldings benefit from the precision and fast tool-switching of the Multi-function CNC Spindle.

Architectural Decorative Wood Structures

Columns, arches, intricate grooves, and structural profiles gain the dimensional integrity that the CNC Compound Processing Head was engineered to deliver.

Small-Batch Custom Work with High Variability

With the 8-function capability consolidated, even workshops handling diverse SKUs can rely on the streamlined workflow of the Woodworking Boring Milling Head.

FAQ: Answers to Common Technical Questions

Q1: Can the new head be installed on existing CNC machines?

Yes. Most machines can be upgraded to the 8-in-1 CNC Woodworking Head with minor structural adjustments.

Q2: How does Haopai maintain high-accuracy positioning?

A reinforced locking mechanism ensures repeatability of ±0.01mm across all Protean Milling Drilling Head functions.

Q3: Does integrated design reduce rigidity?

No. The Multi-function CNC Spindle uses a reinforced housing and optimized internal geometry for maximum strength.

Q4: What happens if one function encounters overload?

The CNC Compound Processing Head includes overload-protection algorithms and smart fault diagnostics.

Q5: Is it suitable for long production cycles?

Yes. The Woodworking Boring Milling Head is built for continuous, long-duration industrial workloads.

Conclusion: A Redefinition of CNC Limits

The launch of Haopai’s new 8-function composite head marks more than a product upgrade—it represents a turning point for CNC woodworking. The integration of milling, drilling, boring, and complex shaping into one 8-in-1 CNC Woodworking Head creates an ecosystem where precision, efficiency, and consistency converge. With the Protean Milling Drilling Head, manufacturers can break free from the constraints of multi-machine setups. With the Multi-function CNC Spindle, they gain continuity. With the Woodworking Boring Milling Head and CNC Compound Processing Head, they gain accuracy, speed, and reliability at levels previously unattainable.

Haopai is not just redefining one CNC component—it is redefining the limits of what CNC woodworking can achieve.

Call to Action

Manufacturers ready to push their CNC performance to a new frontier are invited to explore the technical possibilities of the Protean system.

Contact Haopai to experience how an 8-function integrated head can transform modern woodworking production lines from the ground up.