Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

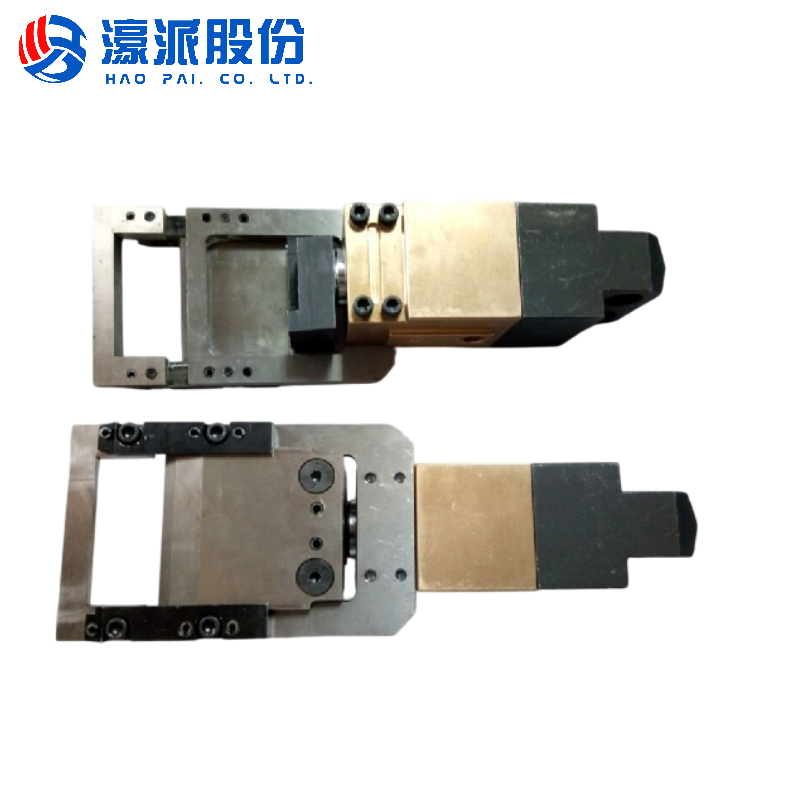

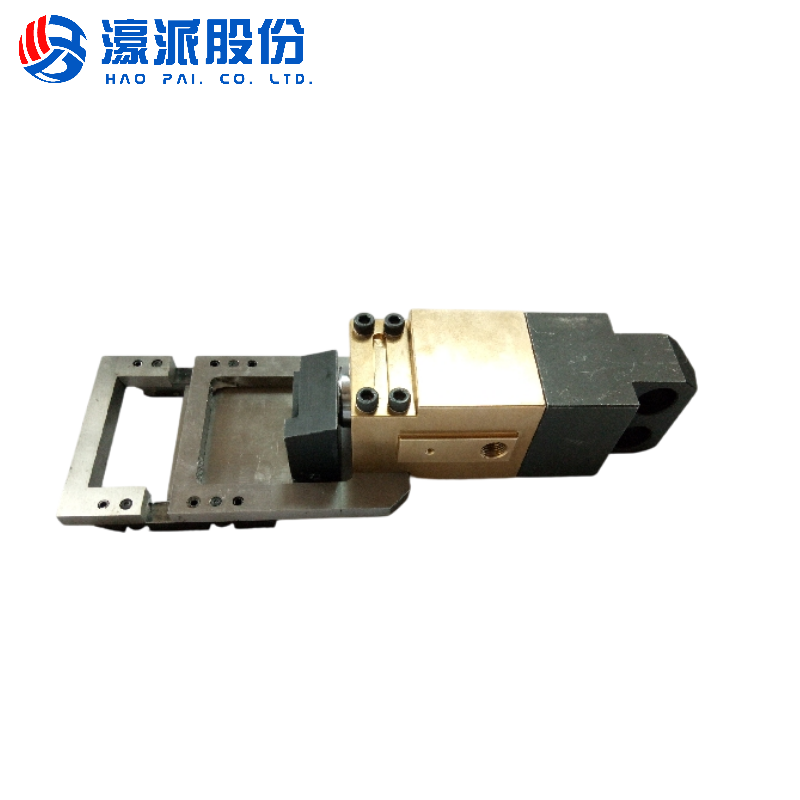

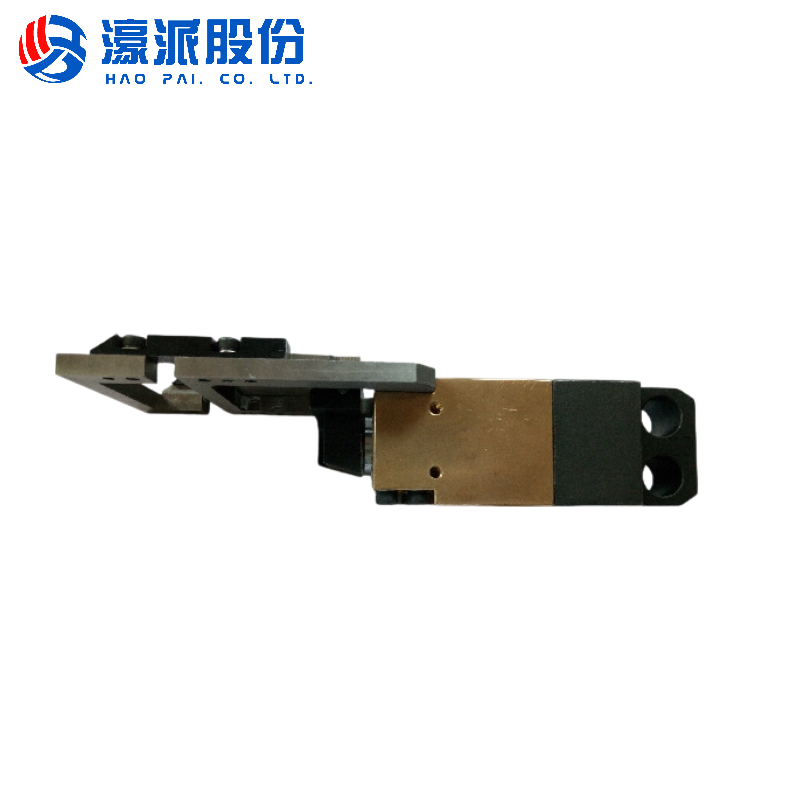

2013141100 A3 PC Homag Woodworking Machine Snipping Blade

- Haopai

- Guangdong, China

- 15-20days

- 1000

- 2013141100 right

- Used on the right side of the double-end edge sealing machine

Product advantages and feature

1. Material Advantages

The cutting knife made of high-strength alloy has outstanding durability and cutting performance.

2. Process advantages

The product adopts advanced manufacturing technology to ensure the sharpness and service life of the blade.

Product Technical Parameters

Used on the right side of the double-end edge sealing machine.

Product Description

1. Accurate control system

The cutting blade unit adopts a heavy-duty edge sealer precision cutting control system, which is specially designed for edge sealing operations to ensure the stability and accuracy of the cutting process. By optimizing the control logic, this system solves the accuracy problems that may arise in the belt cutting process of traditional edge sealing machines, which significantly improves the processing quality of furniture products.

2. Technical background and application

The cutting blade unit is an important part of the edge sealing machine and is mainly used for cutting and trimming after the sealing. In the manufacturing process of panel furniture, the accuracy of the cutting belt directly affects the aesthetics and practicality of the final product. The Haomai cutter unit meets the modern furniture industry's demand for fine processing through advanced technical design.

3. Work in concert with other units

The cutting blade unit usually works in coordination with other units of the edge sealing machine (such as premilling cutters, finishing cutter units, etc.) to form a complete edge sealing processing process. For example, in the Haomai KAL210 edge sealing machine, the cutting knife unit cooperates with the front and rear edge unit, the finishing knife unit, etc. to ensure that the edges of the workpiece after the edge sealing are flat and burrs-free.

4. Industry advantages

As a well-known brand in the field of woodworking machinery, Haomai has been widely used in the furniture manufacturing industry with its cutting blade units due to their efficiency and reliability. The design of this unit fully takes into account the requirements of operational complexity and fineness, can adapt to the processing needs of different workpieces and improve overall production efficiency.

Product application scope

A wide range of products

Cutter cylinder, used to cut the edge band, diameter 40, stroke 36:

Adapting model

TVL100

KFL526

KFL525

KFL326

KFL325

KAR610

KAR370

KAR350

KAR330

KAR310