Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

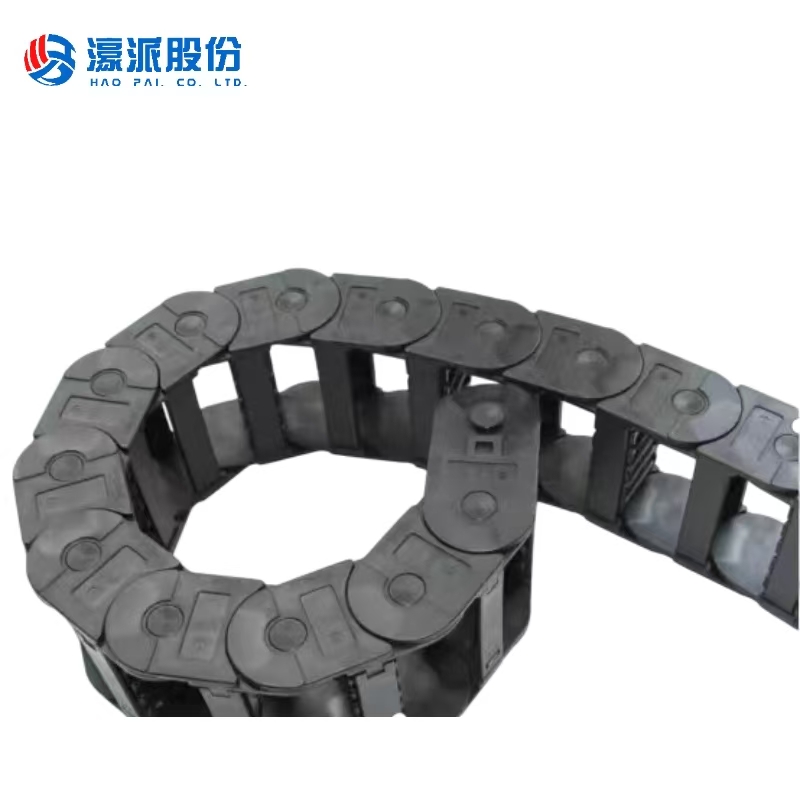

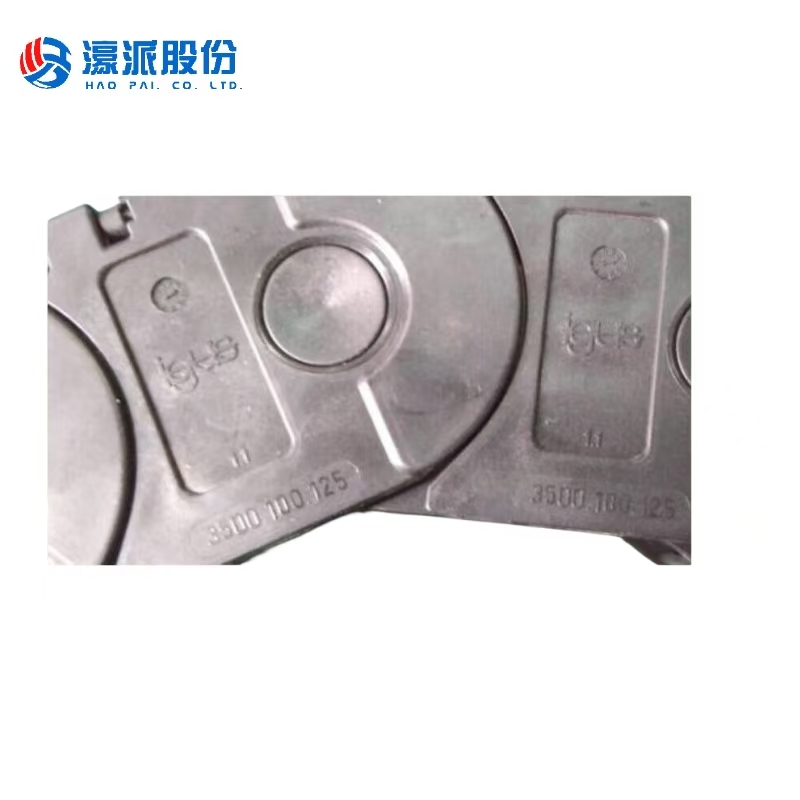

4-007-22-2283 Igus Power Chain 350.100.125.0 Flexible Cable Channel for Hpp180 Homag

- Haopai

- Guangdong, China

- 5-10days

- 100000

- 4007222283

- 350.100.125.0

Product Advantages and Features

Excellent protective performance: The electronic saw chain ensures reliable traction and protection for internal cables, oil pipes, air hoses, etc., preventing damage from friction, impact, and stretching during the reciprocating motion of the electronic saw, thereby extending the lifespan of the pipelines.

Convenient installation and maintenance: The chain consists of numerous interconnected units, each of which can be opened without threading wires. After opening the cover plate, cables, oil pipes, and other components can be placed inside the chain, making installation very convenient. This structure also facilitates later maintenance and replacement of pipelines, reducing maintenance costs and difficulty.

Superior movement performance: The links of the chain rotate freely, producing low noise and high wear resistance, allowing for high-speed movement. It can adapt to the high-frequency reciprocating motion during rapid cutting by the electronic saw, ensuring stable operation of the equipment.

Excellent material properties: Typically made from reinforced nylon and other materials, it has high pressure and tensile load capacity, good toughness, high elasticity, and wear resistance. It also has flame retardant, oil-resistant, salt-resistant properties, as well as certain acid and alkali resistance, maintaining stable performance at high and low temperatures, suitable for use in various environments.

Flexible structural design: Chains in the same series have the same internal height, external height, and pitch, but the internal width and bending radius R can be chosen differently. Partition plates can also be provided to divide the internal space of the chain as needed, facilitating the reasonable arrangement of pipelines of different specifications and types.

Aesthetic and tidy appearance: The chain can organize and protect the cables and other pipelines of the electronic saw, making the equipment look more aesthetically pleasing and tidy, enhancing the overall image of the equipment.

Product Technical Parameters

| Inner Height | The maximum vertical internal space height of the tank chain, determining the maximum diameter of pipelines it can accommodate |

| Outer Height | The overall vertical external height of the tank chain, affecting the adaptability of equipment installation space |

| Inner Width | The horizontal internal space width of the tank chain, which should be selected based on the total number and diameter of pipelines |

| Pitch | The length of a single chain link; the larger the pitch, the fewer the number of chain links per unit length, with slight differences in movement flexibility |

| Bending Radius | The minimum bending arc radius that the tank chain can achieve, which must be larger than the minimum bending radius of the pipeline to avoid pipeline damage |

| Rated Load | The maximum traction and pressure that the tank chain can withstand under normal working conditions, divided into dynamic load and static load |

| Running Speed | The maximum speed of the tank chain when moving with the electric saw, usually in meters per minute (m/min), which needs to match the equipment running speed |

| Operating Temperature Range | The ambient temperature range in which the tank chain can work stably; different materials (such as reinforced nylon, engineering plastics) have different temperature ranges |

| Wear Resistance Coefficient | An indicator to measure the wear resistance of the tank chain material; the lower the coefficient, the better the wear resistance and the longer the service life |

| Material | The core material for making the tank chain, commonly including reinforced nylon 66, nylon PA, engineering plastics, etc., which affects its strength, corrosion resistance, etc. |

| Flame Retardant Grade | The flame retardant performance grade of the tank chain material, usually classified according to the UL94 standard (such as V0, V1 grades), suitable for scenarios with fire protection requirements |

| Corrosion Resistance | The ability of the tank chain to resist erosion by chemicals such as oil, salt, acid, and alkali, which should be selected according to the use environment (such as humid, oily environment) |

Product Application Scope

The core function of an electronic saw chain (also known as an electronic saw-specific cable protection drag chain) is to provide traction and protection for cables, oil pipes, air pipes, and other pipelines during the equipment's movement process. Its application scenarios are highly focused on various working environments and supporting equipment for electronic saws, which can be specifically categorized into the following types:

1. Woodworking processing scenarios

This is the most core application area for electronic saw chains, suitable for various woodworking-specific electronic saws, mainly including:

Furniture manufacturing workshops: Used for table saws, panel saws, precision cutting saws, etc. These types of electronic saws require high-frequency reciprocating movement of the saw blade or worktable. The chain can protect motor cables, CNC signal cables (such as positioning sensor cables), avoiding wear from wood chips and wood dust, while preventing the cables from tangling and affecting cutting accuracy.

Solid wood processing production lines: Suitable for curve saws, reciprocating saws, etc., used for solid wood cutting. When dealing with irregular wood (such as chair legs, curved decorative pieces), the saw head needs to move at multiple angles. The chain can flexibly bend with the saw head, protecting power supply and control pipelines, adapting to complex cutting paths.

Plywood processing field: Targeting cutting equipment for particleboard, medium-density fiberboard, and multi-layer solid wood boards (such as electronic panel saws), the chain needs to withstand possible glue residues and slight oil stains in the workshop, while protecting pipelines from being scratched by board edges, ensuring the stability of continuous batch processing.

2. Metal and non-metal material cutting scenarios

With the expansion of electronic saw applications, chains are also adapted to specialized electronic saws for non-wood cutting, typical scenarios include:

Metal thin plate cutting workshops: Used for small electronic metal saws (such as stainless steel plate, aluminum plate cut-off saws), the chain needs to have a certain ability to withstand metal debris impact, while protecting cables from the slight high temperatures generated during cutting (such as metal friction heat). In some scenarios, enhanced nylon material chains with better heat resistance are selected.

Plastic / Acrylic processing scenarios: Suitable for electronic saws cutting plastic sheets, acrylic sheets. In such processing environments, there may be a risk of plastic slag sticking. The chain's closed structure can prevent slag from entering the chain and damaging the pipelines, while its smooth movement characteristics can avoid pipeline breakage caused by plastic debris jamming.

Composite material cutting field: Such as glass fiber boards, carbon fiber boards, and other high-strength materials' specialized electronic saws, the chain needs to withstand higher dynamic loads (due to greater cutting resistance, the traction force on pipelines is stronger when the equipment moves). Typically, high tensile strength models are chosen to ensure no deformation over long-term use.

3. Automation and CNC cutting production line scenarios

In modern industrial production, electronic saws often work in conjunction with automation systems, and the application of chains needs to match the efficiency and precision requirements of the production line:

CNC electronic saw production lines: Such as the "cutting - edge banding - drilling" integrated production line in the furniture industry's CNC cutting saw, the chain needs to protect the signal cables between the CNC system and the saw head, feed mechanism (such as servo motor control cables, position feedback cables), ensuring stable signal transmission, avoiding cutting size deviations caused by pipeline interference.

Automated loading and unloading electronic saw equipment: Equipped with robotic arms or automatic feed devices, the chain needs to run synchronously with the feed mechanism / robotic arm's reciprocating and lifting movements, protecting the equipment and external power supply.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.