Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

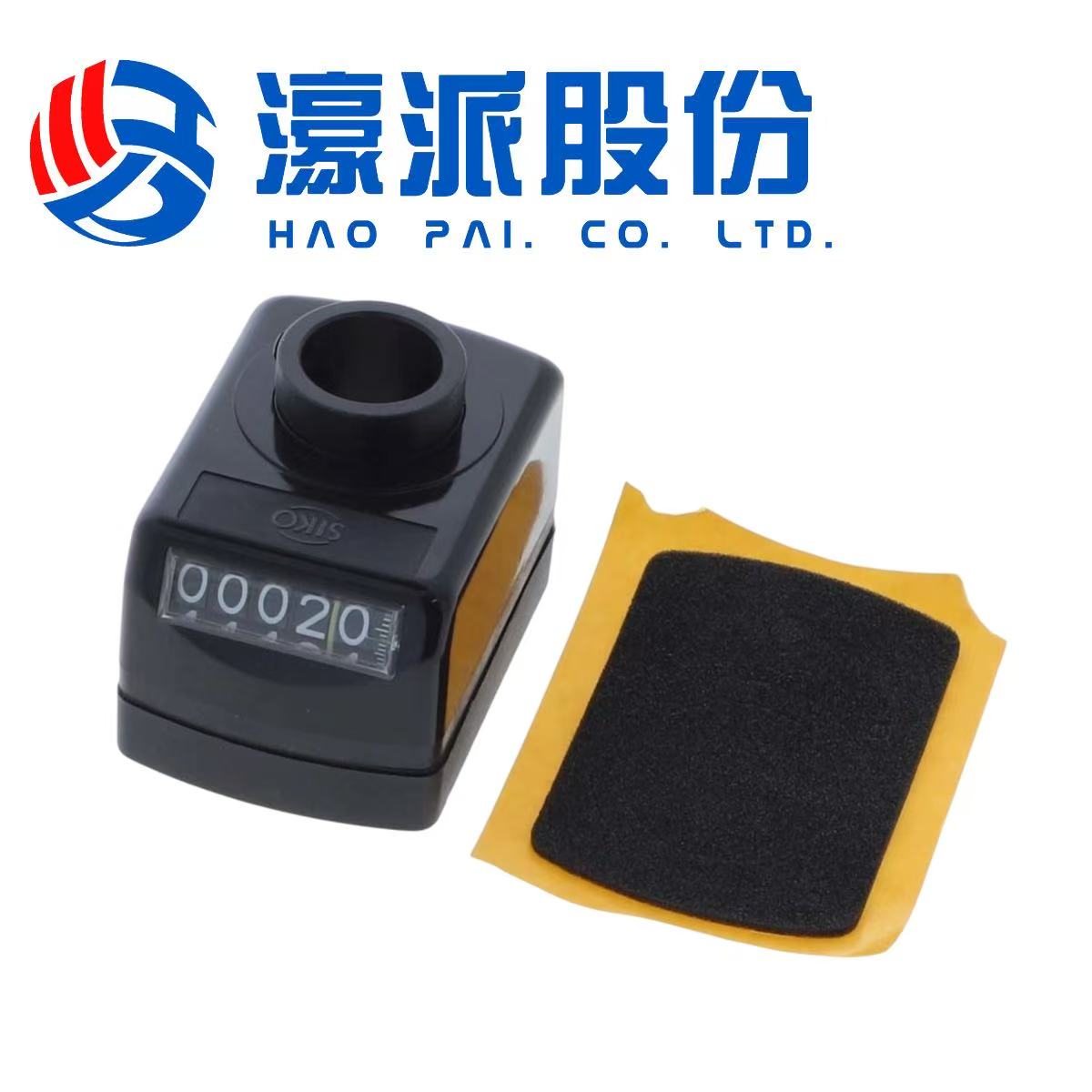

4022030022 Edge Banding Machine Woodworking Accessories Indicator Counter

- Haopai

- Guangdong, China

- 5-10days

- 30 per month

- 0914-2.0-I-20-S-B

Product Advantages and Features

1.Ultimate Accuracy, Zero Errors

Automated Counting: Utilizes high-sensitivity photoelectric sensors for non-contact detection of every panel. Achieves 100% counting accuracy, eliminating human errors like miscounts, duplicates, or forgotten batches associated with manual tracking.

2.Effortless Batch Management, Multiplied Efficiency

Preset Functionality: Easily set your desired batch quantity (e.g., 100 pcs). The counter automatically increments, allowing the operator to focus entirely on loading/unloading and quality inspection, significantly boosting individual productivity.

Audio-Visual Alarm: Upon reaching the preset count, a loud buzzer and bright warning light activate instantly. This provides clear notification that the batch is complete, enabling a seamless transition to the next job and minimizing machine idle time.

3.Data-Driven Insights, Informed Decisions

Visual Production Data: The clear digital display shows real-time output, providing direct and reliable data for shift production statistics, job costing, and order progress tracking. Empowers managers to monitor efficiency and make informed decisions based on accurate data.

4.Robust Reliability, Built to Last

Industrial-Grade Build: Engineered to perform reliably in harsh workshop environments with dust, chips, and interference. Offers excellent durability and very low failure rates.

Broad Compatibility: Designed for standard voltages (e.g., DC12V/24V) and features universal mounting options (e.g., DIN rail), making it easy to install and compatible with most automatic and semi-automatic edge banding machines.

5.Smart Integration, Enhanced Operation

Auto-Stop Interface (Advanced Feature): Select models support an output signal that can automatically command the machine to stop after the preset count is completed. This enables intelligent, closed-loop operation and is a key step towards fully automated production.

Product Technical Parameters

Parameter | Details | |

General Specifications | Display Type | High-brightness red LED digit (0.56 inch) |

Counting Range | 0 ~ 999,999 | |

Preset Range | 0 ~ 999,999 | |

Counting Speed | ≤ 500 counts/minute | |

Power Supply | DC 12V (±10%) or DC 24V (±10%) (Please confirm based on the specific model) | |

Power Consumption | ≤ 3W | |

Dimensions (H x W x D) | 48mm x 48mm x 80mm (Panel cutout: 45mm x 45mm) | |

Mounting Style | Panel-embedded mounting | |

Input Characteristics | Trigger Signal | Supports NPN (Normally Open NO) signal type |

Input Method | Photoelectrically isolated input for superior anti-interference performance | |

Signal Source | Compatible with mechanical contacts, photoelectric sensors, proximity switches, etc. | |

Minimum Pulse Width | ≥ 10ms | |

Output Characteristics (Available on models with auto-stop function) | Output Type | Relay contact output |

Contact Rating | 250V AC / 3A or 30V DC / 5A | |

Output Action | Relay engages upon reaching preset value (Provides NO/NC signal) | |

Alarm Function | Alarm Method | Built-in piezoelectric buzzer (Volume ≥ 70dB) and multi-function indicator light |

Alarm Trigger | Automatically activates when count equals preset value (PV) | |

Environmental Specifications | Operating Temperature | -10℃ ~ +50℃ (14°F ~ 122°F) |

Storage Temperature | -20℃ ~ +70℃ (-4°F ~ 158°F) | |

Operating Humidity | 35% ~ 85% RH (non-condensing) | |

Protection Rating | IP54 (Dust and water splash protected) |

Product Application Scope

Can be applied in large panel furniture manufacturing plants:

It is part of the standard configuration on the production line. The combination of counters and ERP/MES systems provides accurate output data for each shift and production line, which is used for efficiency analysis, hour accounting, and performance management. It is a fundamental part of realizing a digital factory.

Product Description

Comparison Dimension | Professional Electronic Indicator Counter | Mechanical Counter / Manual Counting |

Accuracy & Reliability | Superior Accuracy: Utilizes photoelectric sensors for non-contact detection, eliminating missed or double counts. Accuracy reaches 100%. | Prone to Error: Manual counting is susceptible to distraction, leading to forgotten or repeated counts. Mechanical types can fail due to jamming or poor contact. |

Productivity & Automation | Efficiency Multiplier: Features auto audio-visual alarm upon reaching the preset value, and can trigger machine auto-stop. Operators focus on loading/unloading and quality, enabling seamless batch changeover. | Inefficient: Requires constant mental tallying. Frequent stops to check progress interrupt the production rhythm. Offers zero automation. |

Production Management & Data | Data-Driven Management: Provides precise, real-time output and batch data. Serves as the objective basis for shift reports, labor costing, performance evaluation, and order tracking, enabling lean production. | Management Opaqueness: Relies on paper records or memory. Data is inaccurate and difficult to trace, leading to vague, uninformed management. |

Functionality & Intelligence | Feature-Rich: Supports preset values, accumulation, reset, alarm output (for auto-stop), and multiple signal inputs. Acts as a fundamental unit for smart manufacturing. | Limited Functionality: Mechanical counters only add up; they cannot preset alarms. Manual counting offers no functionality. |

User Experience | Excellent UX: Bright LED display is clear and intuitive. unmistakable audio-visual alerts significantly reduce operator mental burden and lower work intensity. | Poor UX: Requires high concentration, is mentally fatiguing, and is a monotonous task with low error tolerance. |

Long-Term Cost & ROI | Cost Reduction & Efficiency Gain: A one-time investment with long-term returns. Rapid ROI is achieved by preventing material waste and rework from over-production, under-production, or errors, plus the gains from increased productivity. | High Hidden Costs: The hidden costs associated with counting mistakes—material waste, delayed orders, customer complaints—are substantial and costly in the long run. |

Though a small component, this indicator counter is a powerful tool for reducing costs, improving quality, and optimizing management. It transforms your edge bander from a basic processing unit into a smart production cell through precision, automation, and data-driven insights, making it an indispensable efficiency-booster for the modern woodworking shop.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.