Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

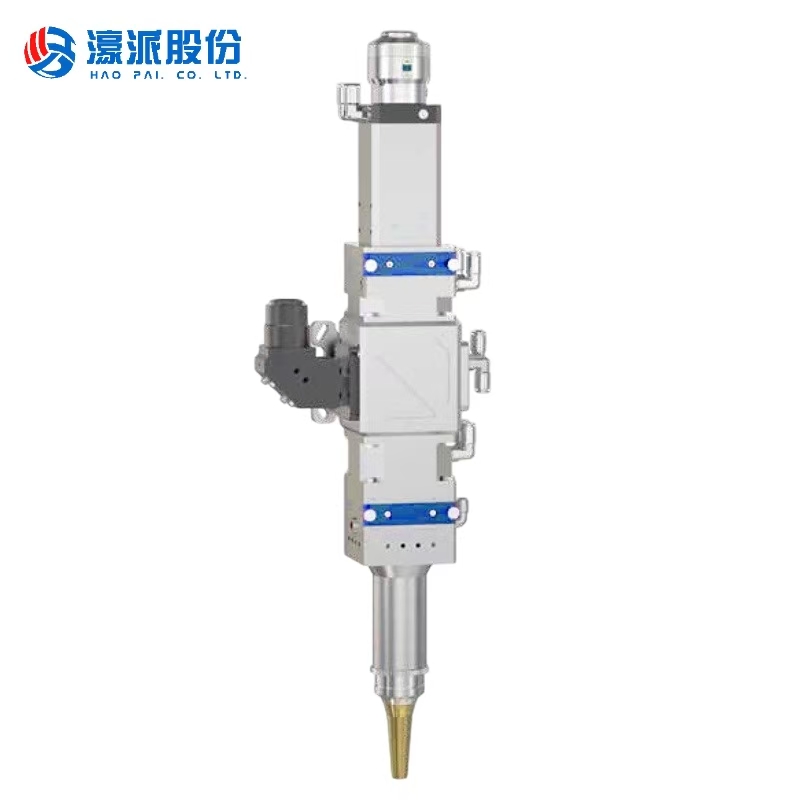

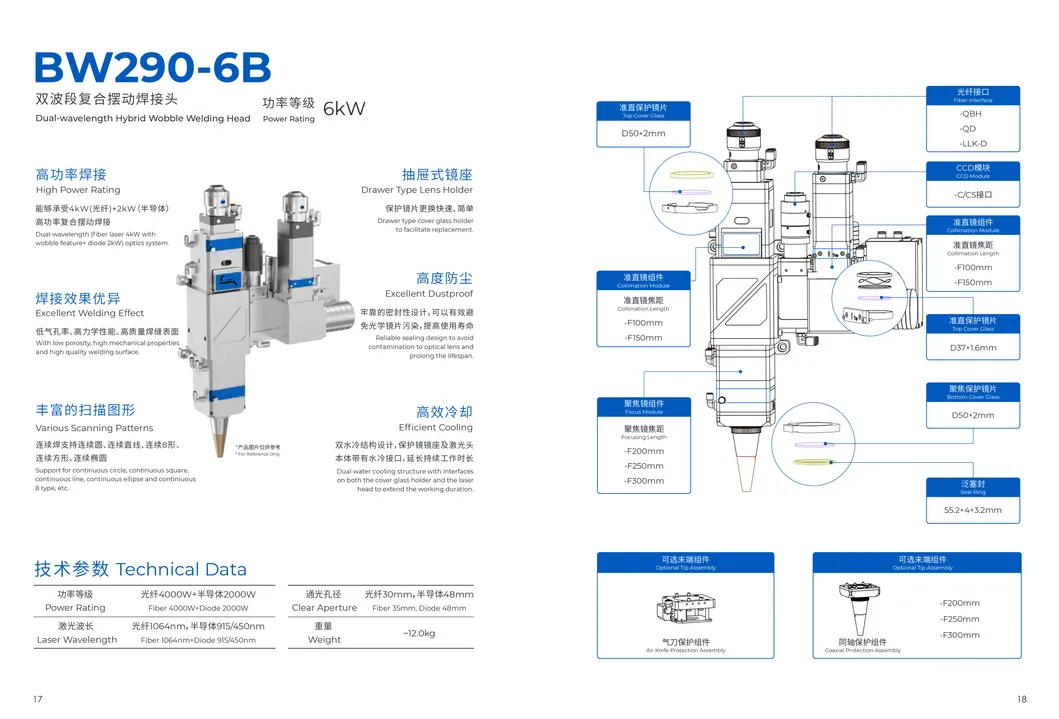

6kw Dual-Wavelength Hybrid Wobble Laser Welding Head

- 30days

- 10 per month

- 6kw Dual-Wavelength

Product Advantages and Features

1.Dual-Wavelength Synergy for Broad Material Compatibility

This welding head integrates two complementary laser wavelengths (typically 1064nm infrared + 1940nm near-infrared), leveraging their respective strengths to tackle challenging materials. The 1064nm laser delivers strong penetration, ideal for thick steel plates and high-hardness alloys, while the 1940nm laser ensures high absorption on highly reflective metals like copper and aluminum—minimizing energy loss and avoiding "cold solder" issues. This hybrid design eliminates the limitation of single-wavelength welding heads, enabling stable, high-quality welding across steel, aluminum, copper, titanium alloys, and dissimilar material combinations.

2.Wobble Technology Enhances Weld Adaptability & Quality

Equipped with a high-precision wobble module (driven by piezoelectric or motor systems), the welding head allows the focused laser spot to move in customizable trajectories (circular, figure-8, linear reciprocating) with adjustable amplitude (0.1-5mm) and frequency (10-500Hz). This feature effectively widens weld seams, fills gaps up to 0.5mm (reducing strict requirements for workpiece fitting), and eliminates defects like incomplete fusion. Additionally, the wobble motion optimizes molten pool flow, resulting in smoother, more uniform weld surfaces that meet strict aesthetic and structural standards.

3.6kW High Power for Efficient Heavy-Duty Welding

With a maximum output power of 6kW, the welding head excels in high-efficiency welding scenarios. It rapidly melts thick materials (e.g., 8mm steel plates, 6mm aluminum plates) and achieves a welding speed over 30% faster than medium-power counterparts. This performance significantly shortens processing cycles for mass production tasks—such as automotive frame welding and power battery module assembly—without compromising weld strength or consistency.

4.Precise Control & Stable Operation for Reliable Output

A built-in precise energy control system maintains power stability within ±1% of the set value, ensuring consistent weld quality across long production runs. The dedicated water-cooling interface (compatible with flow rates ≥3L/min) efficiently dissipates heat generated during 6kW high-power operation, preventing overheating-induced performance degradation or component damage. Combined with an IP54 dust-proof and splash-proof rating, the welding head guarantees reliable operation in harsh industrial environments.

5.Versatile Integration for Diverse Application Scenarios

The lightweight design (approx. 4.2kg, 15% lighter than same-power models) and standard digital communication interface enable seamless integration with 6-axis robotic arms and automated welding platforms—supporting flexible, high-precision welding of complex workpieces (e.g., aerospace structural parts, electronic component pins). It adapts to both micro-welding tasks (e.g., power battery tabs, minimum spot diameter 50μm) and heavy-duty thick-material welding, making it a one-stop solution for new energy, automotive, aerospace, and electronics industries.

Product Technical Parameters

Parameter Category | Parameter Item | Specification/Details |

Laser Performance | Maximum Output Power | 6kW |

Dual-Wavelength Combination | 1064nm (infrared) + 1940nm (near-infrared) (customizable for specific applications) | |

Focused Spot Diameter | 50μm - 200μm (adjustable via interchangeable lenses) | |

Welding Speed Range | 0.5m/min - 10m/min (varies by material type, thickness, and welding mode) | |

Energy Control Precision | ±1% of set power | |

Wobble Functionality | Wobble Trajectories | Circular, figure-8, linear reciprocating (selectable via control system) |

Wobble Amplitude | 0.1mm - 5mm (stepless adjustment) | |

Wobble Frequency | 10Hz - 500Hz (adjustable for weld quality optimization) | |

Wobble Drive System | Piezoelectric/motor-driven (high precision, low noise) | |

Structural & Physical | Weight | Approx. 4.2kg (15% lighter than same-power non-wobble welding heads) |

Product Application Scope

New Energy Power Battery Manufacturing

In the production of lithium-ion power batteries (for electric vehicles and energy storage systems), this welding head excels in critical processes such as battery tab welding and battery case sealing. Its dual-wavelength combination (1064nm + 1940nm) ensures high absorption of laser energy by copper and aluminum tabs—solving the problem of high reflectivity in traditional single-wavelength welding and avoiding defects like cold solder or burn-through. The wobble function (with 0.1-5mm adjustable amplitude) effectively fills small gaps between tabs, ensuring consistent weld strength and low internal resistance. Additionally, its 6kW power enables fast welding of multi-layer tab stacks, meeting the high-efficiency requirements of mass battery production lines.

Automotive Manufacturing

For automotive OEMs and component suppliers, this welding head supports key welding tasks across the vehicle body, powertrain, and electrical systems. It is ideal for welding thick steel plates (0.3-10mm) in automotive frames and chassis—leveraging 6kW high power to achieve deep penetration and high weld strength, while the wobble technology optimizes seam formation and reduces post-weld grinding. In electric vehicle (EV) motor production, it handles the welding of copper stators and aluminum housings: the dual-wavelength design adapts to the dissimilar material properties, and the precise energy control ensures no damage to delicate motor components. It also meets the automation needs of automotive production lines, seamlessly integrating with 6-axis robotic arms for continuous, high-precision welding.

Product Description

Description Category | Detailed Information |

Core Positioning | A high-performance laser welding core component designed for industrial manufacturing, integrating 6kW high power, dual-wavelength hybrid technology, and precise wobble function to address diverse welding challenges. |

Key Technologies | 1. Dual-Wavelength Hybrid Tech: Combines 1064nm (strong penetration for thick materials) and 1940nm (high absorption for reflective metals like Cu/Al) lasers to break single-wavelength limitations.2. Wobble Tech: Piezoelectric/motor-driven module supports customizable trajectories (circular/figure-8/linear), 0.1-5mm amplitude, 10-500Hz frequency for gap filling and weld optimization. |

Power & Performance | - Maximum Output Power: 6kW, enabling rapid melting of thick materials (steel up to 10mm, aluminum up to 8mm).- Welding Speed: 0.5-10m/min (varies by material), 30% faster than medium-power counterparts.- Energy Control Precision: ±1% of set power for consistent weld quality. |

Structural & Protective Features | - Weight: Approx. 4.2kg (15% lighter than same-power non-wobble models) for easy automation integration.- Housing: High-strength aluminum alloy with anti-corrosion/heat-resistant coating.- Protection Rating: IP54 (dust-proof, splash-proof) for industrial environments.- Cooling: Water-cooling (≥3L/min flow rate, 5-30℃ inlet temp) for stable high-power operation. |

Compatibility & Integration | - Fiber Interface: QD100/QBH (compatible with standard high-power laser fibers).- Automation Compatibility: Seamless integration with 6-axis robotic arms via EtherCAT/Profinet digital interfaces.- Material Compatibility: Steel, aluminum, copper, titanium alloys, and dissimilar material combinations. |

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.