Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

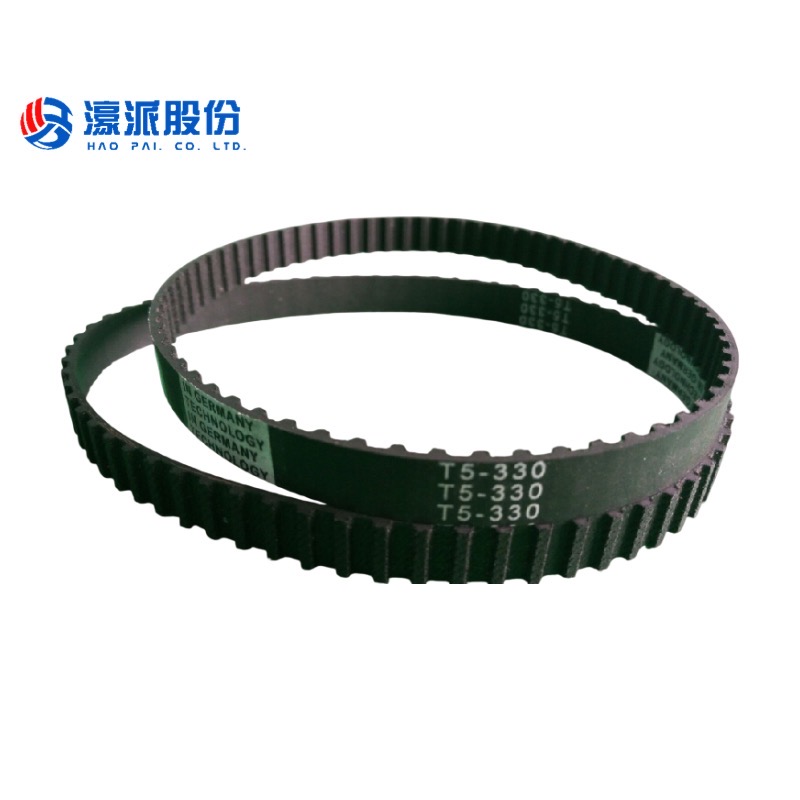

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

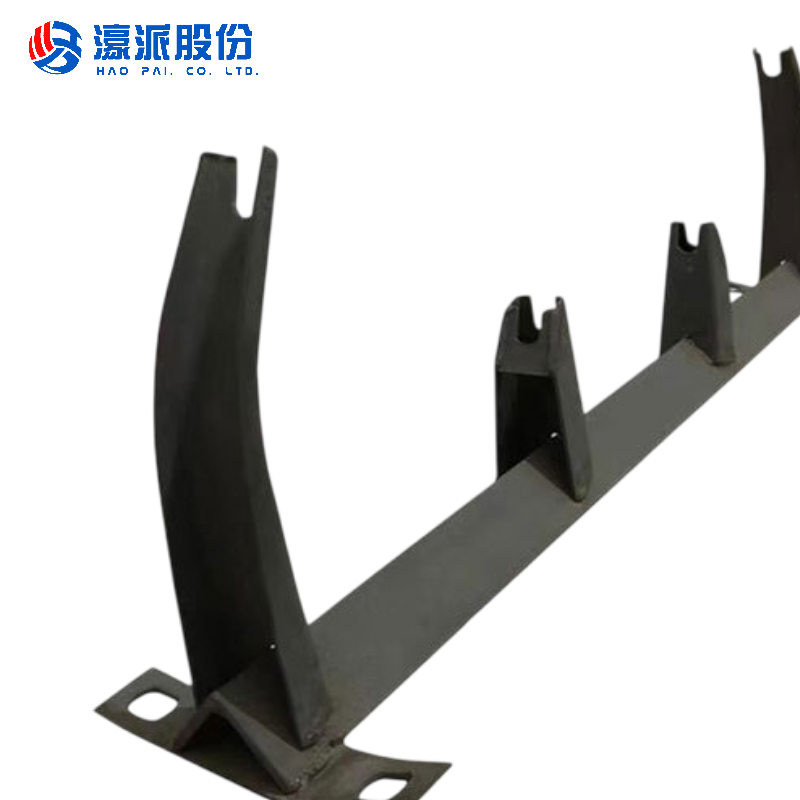

Adjustable Supports

- Haopai

- Foshan, Guangdong, China

- 20-30days

- 1000

- custom made

- custom made

Product Advantages and Features

1. Convenient and efficient adjustment

The adjustable bracket design allows users to quickly adjust the height without turning the support feet in turn, simplifying the operation process and significantly improving work efficiency.

2. Take into account the level adjustment

While adjusting the height, the bracket can also maintain its level stability, avoiding the tedious steps of requiring additional calibration levels after adjustment of the traditional bracket.

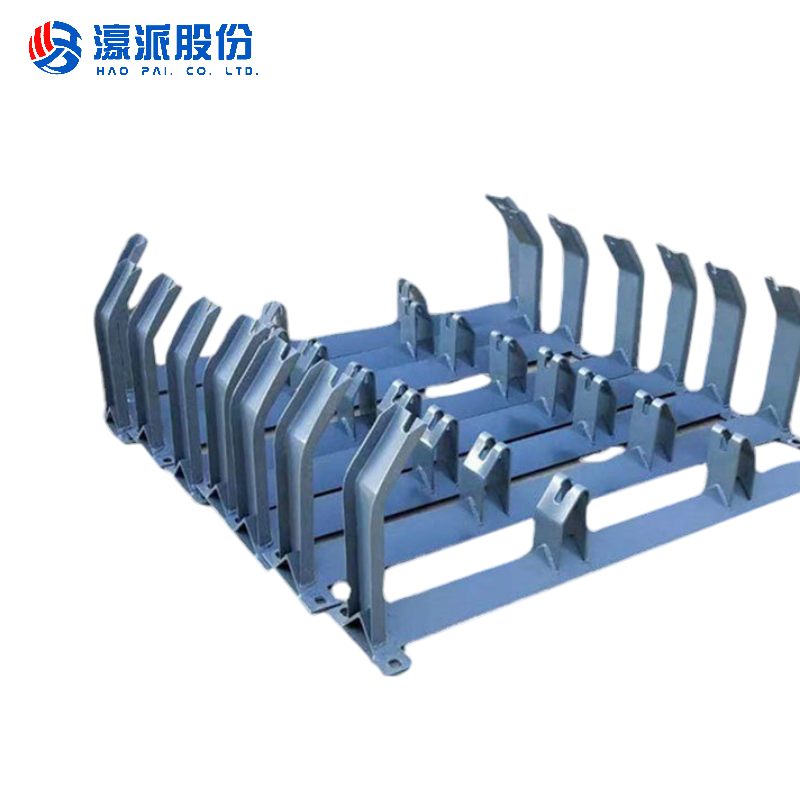

3. Strong adaptability

The bracket can flexibly adjust the conveying length according to different conveying needs, and is suitable for a variety of scenarios, enhancing the versatility and adaptability of the equipment.

4. Energy conservation and environmental protection

As part of the adjustable energy roller conveyor line, the bracket design focuses on energy efficiency, helps users reduce energy consumption, and is in line with the green production concept.

5. Structural optimization

The bracket is designed in a modular way for easy installation and maintenance while ensuring the stability and durability of the conveyor line.

Product Technical Parameters

Parameter Category | Specific parameters |

Specific parameters | Including the bracket body and positioning boss |

Adjustment method | The height can be adjusted freely through threaded lifting pipes, and some designs support horizontal adjustment and conveying length adjustment. |

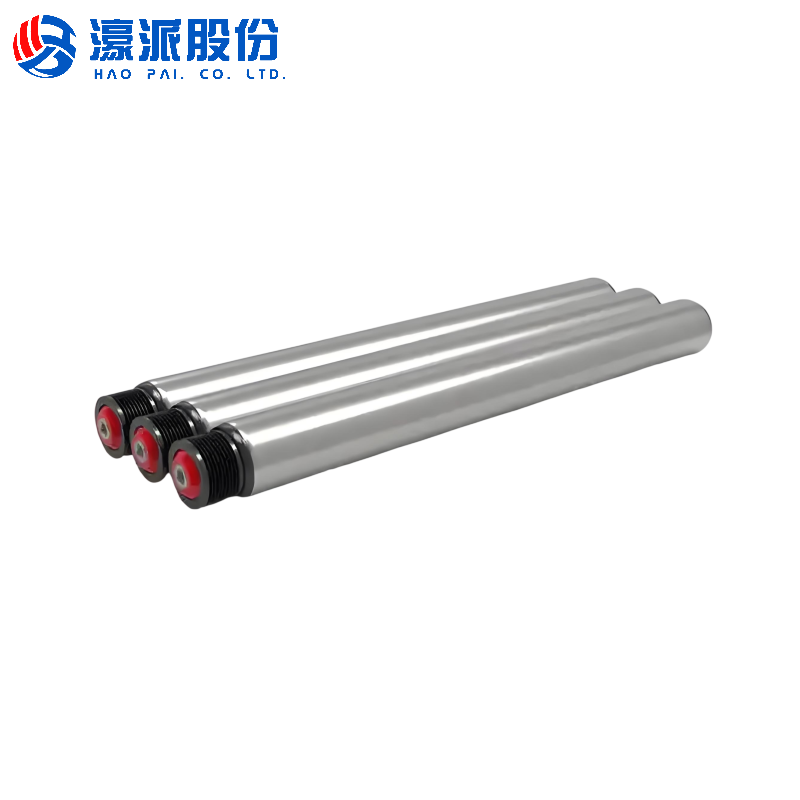

Material | The material of the bracket body is not clear, but the roller material can be galvanized, aluminum-plated, stainless steel, PVC, etc. |

Applicable scenarios | Suitable for the conveying of items on the bottom plane, it can form a complex logistics system with other conveying equipment. |

Driver form | Classified into powered, unpowered, electric rollers and other types. |

Product Application Scope

The adjustable brackets of roller conveyor lines have wide applications in many industrial fields, and their core value lies in their ability to flexibly adapt to different conveying needs and environments. The following are the relevant specific application scenarios:

1. Fully automatic packaging production line

In the fully automatic packaging production line, the drum conveys materials and products through the rotation of the drum, ensuring the smooth progress of the packaging process. The adjustable bracket plays a key supporting role in this scenario and can be adjusted according to the height requirements of the production line to ensure smooth connection between the conveyor line and other equipment (such as packaging machines and box sealing machines).

2. Conveyors of heavy-duty materials such as ceramic tiles

For heavy or fragile materials such as ceramic tiles, the conveying process requires high stability and accuracy. The adjustable bracket can achieve precise control of material transportation by designing the first bearing seat group and the second bearing seat group, and avoid material damage or transportation interruption caused by height mismatch.

3. Power transmission line installation

In the field of power delivery, adjustable brackets can be used to erect conveyor lines, and their side-mounted shells and crossbar designs can adapt to different terrain and installation conditions. By adjusting the height and angle of the bracket, ensure the stability and safety of the conveyor line.

4. Energy-saving roller conveying system

The adjustable bracket can solve the problem of cumbersome adjustment of traditional conveyor lines in the energy-saving drum conveyor line. By quickly adjusting the height and level of the bracket, not only improves work efficiency, but also flexibly expands according to the conveying length requirements, suitable for a diverse production environment.

5. Accumulation roller conveying system

In situations where materials need to be temporarily stopped or stored, the adjustable bracket and the accumulation roller can achieve accurate control and efficient transport of materials. This design is especially suitable for logistics sorting, warehousing and other scenarios, improving overall operating efficiency.

In short, the adjustable bracket of the drum conveyor line has shown a wide range of application prospects in many fields such as packaging, power, logistics, etc., and can meet the conveying needs in different scenarios.

Product Description

The adjustable bracket of the drum conveyor line is a support device that can flexibly adjust width and height. It is widely used in automated assembly lines to improve production efficiency and adapt to different conveying needs. The following describes it from three aspects: efficiency, cost and installation method:

1. Improve efficiency

The adjustable bracket can quickly adjust the width and height of the bracket through optimized design to meet the transportation needs of different materials. For example, some patented technologies adopt powerless adjustment method, simplifying the operating process and significantly improving the adjustment efficiency. In addition, the drum conveyor line itself has the characteristics of large conveying volume and fast speed. The stability of the adjustable bracket further ensures the conveying efficiency, which is particularly suitable for scenarios where multiple varieties of collinear shunt transportation are carried out.

2. Cost control

In terms of cost, the design of the adjustable bracket takes into account both economical and practicality. Its modular design reduces installation and maintenance costs, can quickly adapt to changes in production lines, and reduce downtime due to equipment adjustments.

3. Installation method

The installation ease of adjustable bracket is one of its major features. According to patent information, the bracket usually includes a lifting and sliding support trailer and a beam on the top of the frame. Some models are also equipped with reverse chains to facilitate users to adjust the height and position according to actual needs. In addition, some designs adopt symmetrical upper and lower bracket structures, which enable rapid fixing through adjustment devices, further simplifying the installation process.

In summary, the adjustable bracket of the drum conveyor line can significantly improve the flexibility and economy of the production line through efficient adjustment, low-cost design and convenient installation, and is suitable for all kinds of automated conveying scenarios.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.