Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

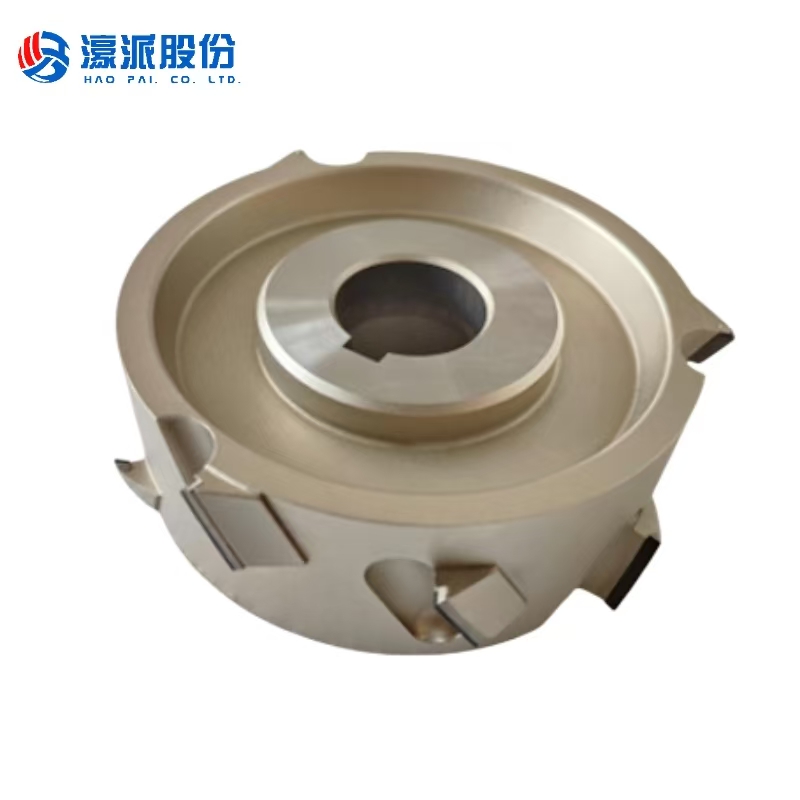

CNC Cutter

- Makita

- Made in Japan

- 2-3days

- 100 pcs month

- CB-153

- 181444-0

Product Advantages and Features

1.Genuine Makita OEM Part

-Exact OEM replacement (Part No. 181444-0).

-Precision-matched dimensions, spring force and contact angle for drop-in fit—no re-grinding required.

2.High-Performance Compound

-High-purity electro-graphite blended with copper powder.

- Low electrical resistance (< 0.8 mΩ) and high thermal conductivity keep running temperature low under continuous load.

-Self-lubricating surface limits commutation sparking to ≤ 1.5 grade, reducing EMI and protecting motor electronics.

3.Extended Service Life

-High-density impregnation: ≥ 1.85 g/cm³.

-Wear rate < 0.15 mm per 100 h—about 40 % better than conventional brushes.

-Silver-plated shunt contact reduces local heating and prevents edge chipping.

4.Tool-Free Quick Change

-Snap-on cap with integrated lead wire allows 30-second field replacement without tools.

-Standard 5.2 × 9.3 × 15 mm size minimizes inventory SKUs.

5.Broad Compatibility & Cost Efficiency

-Fits Makita 9557HN/9558HN angle grinders, 4310 jigsaw, BO3710 sander and more.

-Bulk price < 10 % of typical aftermarket tool repair cost, delivering superior value versus non-OEM alternatives.

Product Technical Parameters

| Item | Specification |

| Part Number | 181444-0 (OEM) |

| Series / Type | CB-153 (Makita genuine carbon brush) |

| Material | High-purity electro-graphite + copper-powder composite,silver-plated shunt tip |

| Dimensions | 5.2 mm (W) × 9.3 mm (T) × 15 mm (L) |

| Density | ≥ 1.85 g cm⁻³ |

| Bulk Resistivity | ≤ 0.8 mΩ·cm |

| Wear Rate | < 0.15 mm / 100 h (at rated load) |

| Commutation Spark Grade | ≤ 1.5 |

| Operating Temperature | –20 °C … +150 °C |

| Spring Pressure | 18 kPa ± 2 kPa (nominal) |

| Applicable Models | Makita 9557HN,9558HN angle grinders; 4310 jigsaw; BO3710 sander etc. |

| Origin | Made in Japan |

Product Application Scope

1.Primary Tool Models

-Makita 9557HN / 9558HN angle grinders.

-Makita 4310 curve saw.

-Makita BO3710 pad sander.

-9553/9554/9555/9556/9559 series 100–125 mm angle grinders.

-All Makita hand-held power tools that use 5.2 × 9.3 × 15 mm carbon brushes.

2. Industries & Applications

-Construction & renovation: wall sanding, metal cutting, stone chamfering.

-Automotive repair: weld seam grinding, sheet-metal shaping.

-Furniture manufacturing: wood surface finishing, lacquer polishing.

- Industrial maintenance: on-site equipment service, mold deburring.

-Home DIY: small-scale crafting and routine repairs.

3.Compatible Third-Party Equipment (same 5.2 × 9.3 × 15 mm size)

-Other brands’ 100–125 mm angle grinders.

-Mini cut-off saws, circular saws, planers, and any DC series-motor tools.

Product Description

| Advantage | OEM Perfect-Fit GuaranteePart No | 181444-0 is the official Makita reference. Dimensions, spring force and contact angle are 100 % matched to the original commutator—install and immediately restore factory performance with no post-grinding required |

| High-Conductivity, Low-Spark Formula | High-purity electro-graphite + copper-powder composite delivers bulk resistivity ≤ 0.8 mΩ·cm and lower temperature rise under continuous heavy load. Commutation sparking ≤ grade 1.5 effectively suppresses EMI and protects the motor controller | |

| Double-Life Engineering | High-density impregnation gives density ≥ 1.85 g/cm³ and wear rate < 0.15 mm per 100 h—about 40 % lower than standard brushes. A silver-plated shunt tip reduces contact resistance and prevents local overheating or edge chipping | |

| 30-Second, Tool-Free Replacement | Snap-on cap with integrated lead wire lets you swap the brush in 30 seconds without a screwdriver; the universal 5.2 × 9.3 × 15 mm footprint cuts spare-part SKUs | |

| Multi-Model Compatibility & Maximum Value | Fits Makita 9557HN/9558HN angle grinders, 4310 jigsaw, BO3710 pad sander and other 100–125 mm hand-held tools. Bulk OEM price is less than one-tenth of the after-market tool price, delivering far lower total cost of ownership than aftermarket alternatives. |

As long as your tool requires a 5.2 × 9.3 × 15 mm carbon brush, the CB-153 181444-0 is ready to drop in as an OEM-grade spare.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.