Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

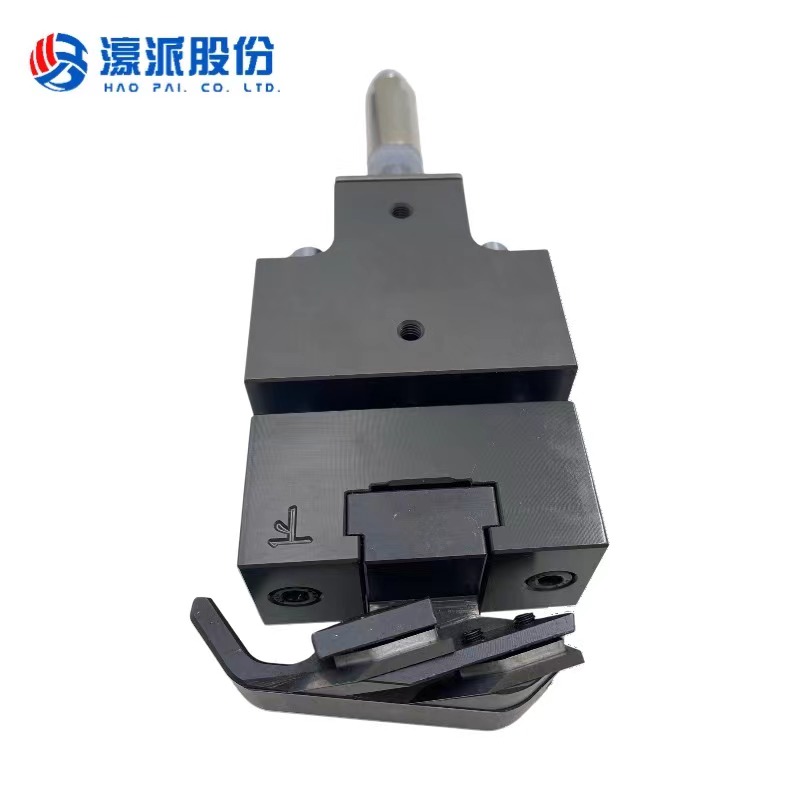

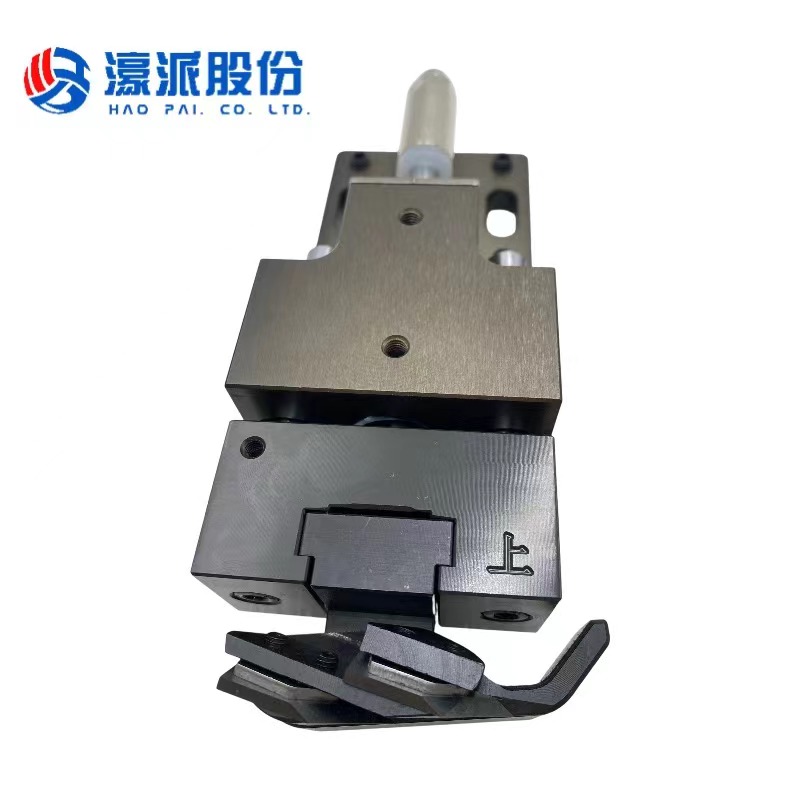

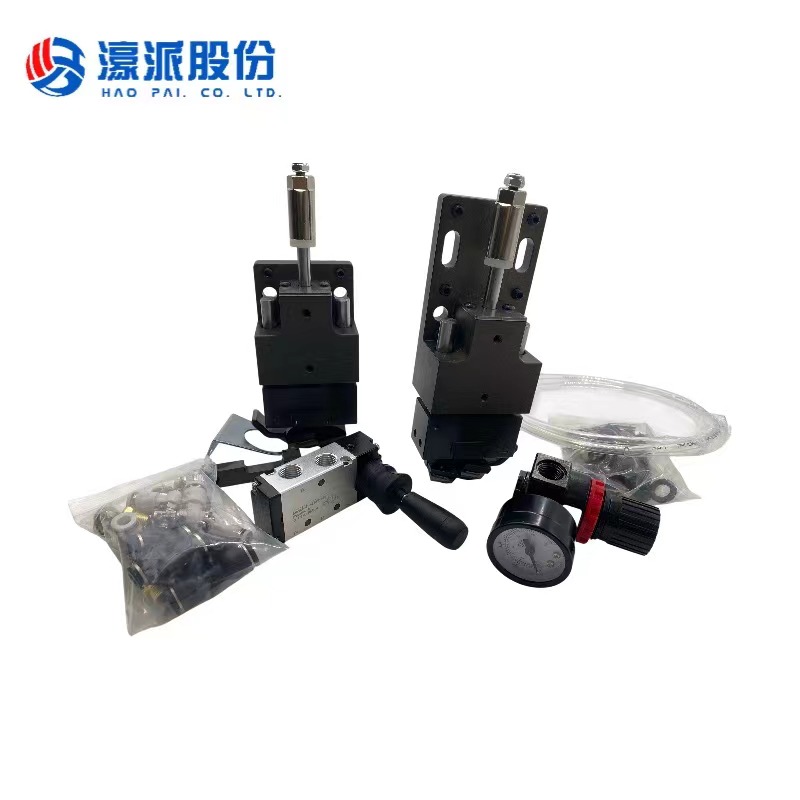

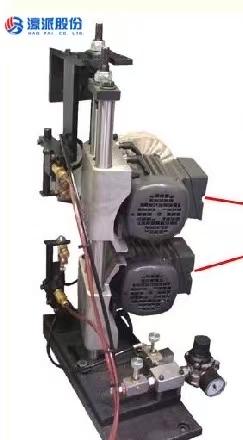

Flexible Horizontal Scraping Unit

- Haopai

- China

- 3-5days

- 50 pcs month

- HOPS

Product Advantages and Features

1. Precise Adaptability:Designed exclusively for crawler machines in woodworking machinery, with dimensions and installation interfaces that perfectly match the operation process of crawler machines. It can be quickly assembled without additional modification, significantly reducing equipment commissioning time, ensuring stable collaborative operation with crawler machines, and avoiding processing errors caused by adaptability issues.

2. Excellent Flexible Material:Made of high-elasticity and wear-resistant flexible polymer materials, it has outstanding deformation capacity. When in contact with the wood surface, it can closely fit the irregular contours of wood (such as curved surfaces and special-shaped edges), effectively removing impurities like wood chips and wood glue remaining on the crawler surface. At the same time, it prevents scratches on the crawler body and wood workpieces, protecting the integrity of equipment and processing materials.

3. Efficient Cleaning Capacity:The scraper edge is treated with a special process, achieving a proper balance between sharpness and flexibility. During the high-speed operation of the crawler machine, it can quickly scrape off various contaminants attached to the crawler surface without easy accumulation of debris. It continuously keeps the crawler clean, ensuring stable traction of the crawler for wood conveying, and reducing the decline in processing efficiency and workpiece positioning deviation caused by crawler slipping.

4. Long-term Durability:The material itself has excellent anti-aging and anti-fatigue properties, which can withstand the long-term high-frequency operation intensity of woodworking machinery, as well as the erosion of dust and slight moisture in the wood processing environment. Its service life is much longer than that of ordinary rigid scrapers, reducing the frequency of scraper replacement and lowering equipment maintenance costs and downtime losses.

5. Protection of Workpiece Quality:The flexible material will not cause hard friction or indentation on the wood surface during operation, making it especially suitable for wood processing scenarios with high surface requirements such as solid wood and veneered boards. It ensures that the surface of processed wood workpieces is smooth and flat, improving the product yield and meeting the quality standards of high-end wood products.

Product Technical Parameters

| Basic Information | Product Name | Flexible Scraper for Crawler Machines in Woodworking Machinery |

| Applicable Equipment | Woodworking crawler conveyor/processing integrated machine, crawler sander, and other woodworking crawler machines | |

| Core Function | Crawler surface cleaning (removing wood chips, wood glue), workpiece surface protection | |

| Material Performance | Scraper Body Material | High-elasticity polyurethane (PU)/nitrile rubber (NBR) (optional) |

| Temperature Resistance Range | -20℃~80℃ (continuous operation) | |

| Wear Coefficient | ≤0.08 (per GB/T 3960-2016 standard) | |

| Dimension Specifications | Scraper Length | 300mm, 500mm, 600mm (standard models), customizable (max. 2000mm) |

| Scraper Thickness | 8mm, 10mm, 12mm (standard models), customizable 5mm-20mm | |

| Mounting Hole Spacing | 50mm/100mm (standard), adaptable to crawler machine mounting positions | |

| Adaptation Range | Adaptable Crawler Width | 150mm-1200mm (covering mainstream woodworking crawler specifications) |

| Adaptable Crawler Speed | 0-15m/min (meeting high-frequency woodworking operation needs) | |

| Cylinder-Type Specific Parameters | Working Air Pressure | 0.4MPa-0.8MPa |

| Pressure Adjustment Precision | ±0.02MPa | |

| Response Time | ≤0.3s (pressure adjusted to set value) |

Product Application Scope

1. Woodworking Crawler Conveyor/Processing Integrated Machine Scenario: It is compatible with various woodworking crawler conveyor and processing integrated equipment. During wood conveying, it can real-time remove wood chips, wood powder generated from wood cutting and sanding, and wood glue particles remaining from the gluing process. It avoids problems such as crawler slipping and conveying jams caused by impurity adhesion, ensures the positioning accuracy of wood in processing links like cutting, drilling, and grooving, and is suitable for batch operation scenarios such as panel furniture production lines and solid wood door and window processing lines.

2. Crawler Sander Scenario: Aiming at the operation characteristics of crawler sanders (including wide-belt sanders, curved sanders, etc.), the flexible scraper can closely fit the crawler surface of the sander, and remove wood fiber debris and sandpaper wear particles generated during the sanding process. It prevents debris from embedding into the crawler texture to affect the uniformity of sanding pressure, avoids defects such as sand marks and missed sanding on the wood surface, and is suitable for crawler cleaning needs before/after sanding of various materials such as solid wood boards, laminated wood, and veneered boards.

3. Woodworking Crawler Gluing Machine Scenario: In the wood gluing operation of crawler gluing machines, the flexible scraper can efficiently scrape off liquid wood glue and hot-melt glue residues remaining on the crawler surface, preventing hard blocks formed after glue layer curing from scratching the wood surface or affecting the uniformity of subsequent gluing. It is especially suitable for the veneer gluing process in the production of plywood and blockboard, ensuring continuous and stable conveying of the crawler and reducing equipment downtime for cleaning caused by glue accumulation.

4. Crawler Woodworking Engraving Machine Scenario: It is compatible with the crawler conveying system of crawler woodworking engraving machines. Before wood engraving processing, it removes dust and tiny wood chips on the crawler surface to ensure that the wood does not shift during the engraving process; after engraving, it further cleans the engraving debris remaining on the crawler to provide a clean environment for the next batch of workpiece conveying. It is suitable for high-precision processing scenarios such as customized wood carvings and furniture decorative part engraving.

5. Other Woodworking Crawler Auxiliary Equipment Scenarios: It can also be applied to auxiliary equipment such as woodworking crawler panel turnover machines and crawler sorters. It removes impurities generated from wood transfer and sorting on the crawler surface, ensures the smoothness of the equipment in wood turnover and classified conveying links, reduces equipment maintenance frequency, and is suitable for multi-link crawler equipment supporting needs in production processes such as whole-house custom furniture and solid wood flooring.

Product Description

Product Positioning | Exclusive supporting cleaning component for crawler machines in woodworking machinery, focusing on solving the problem of impurity residues on the crawler surface to ensure equipment operation accuracy and workpiece quality |

Core Structure | The main body is a flexible scraping layer (high-elastic polymer material), matched with a metal/engineering plastic mounting base; the cylinder type additionally integrates a cylinder drive module and a pressure adjustment component |

Working Principle | Relying on the adhesion of flexible materials, it closely contacts the crawler surface and removes impurities such as wood chips and wood glue through scraping action; the cylinder type can adjust the scraping force through air pressure to adapt to different working conditions |

Core Advantages | 1. Flexible material prevents scratches (protects crawler and workpieces); 2. Precise adaptation without modification; 3. Efficient cleaning reduces failures; 4. Durable and anti-damage reduces maintenance |

Applicable Scenarios | Woodworking crawler conveyor/processing integrated machine, crawler sander, crawler gluing machine, crawler engraving machine and crawler auxiliary equipment |

The flexible scraper for crawler machines in woodworking machinery is a core cleaning component specially developed for woodworking crawler equipment, aiming to solve equipment failures and workpiece quality problems caused by impurity residues during crawler operations. Its main body is made of high-elasticity and wear-resistant polymer flexible material, matched with a base structure adapted to the crawler machine's mounting interface, which can be quickly assembled without additional modification to achieve "ready-to-use".

During operation, relying on the excellent adhesion of the flexible material, the scraper can closely follow the surface contour of the crawler, efficiently scraping off wood chips and wood powder generated from wood cutting and sanding, as well as wood glue particles and hot-melt glue residues remaining from the gluing process. It avoids impurities embedding into the crawler texture, which may cause conveying slippage and positioning deviation, and at the same time eliminates the risk of scratches on the crawler body and wood workpieces caused by rigid components. It is especially suitable for processing scenarios with high surface requirements such as solid wood and veneered boards.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.