Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

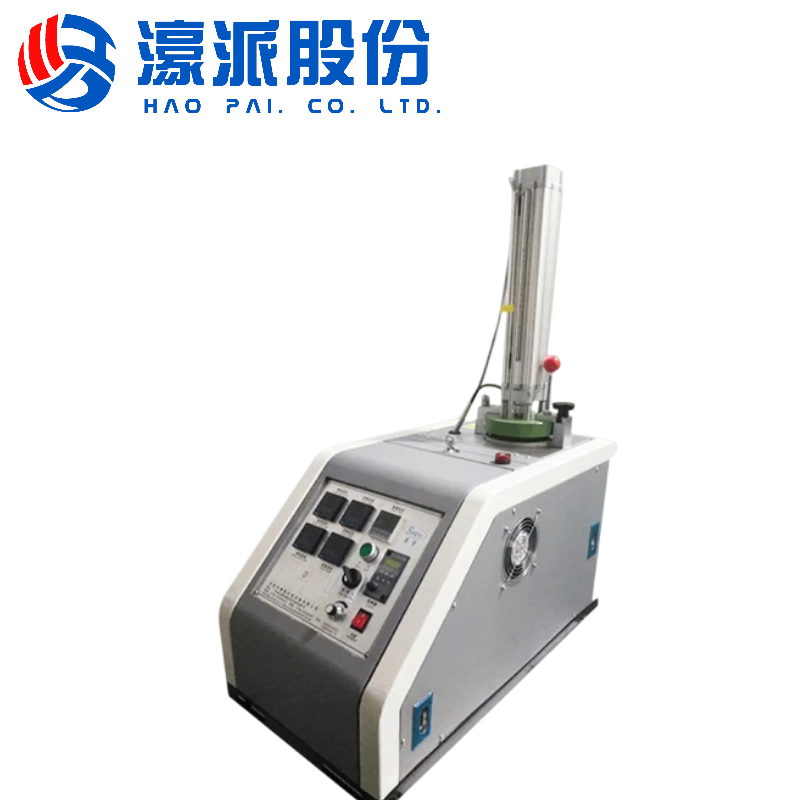

Homag Woodworking Edge Banding PUR Hot Melt Adhesive Machine

- Haopai

- Product origin Made in Foshan, ChinaGuangdong, China

- 5-10days

- Supply capacity 100 pcs month

- SP-PUR2.5P

- SP-PUR2.5P

2.5P PUR Hot Melt Glue Machine

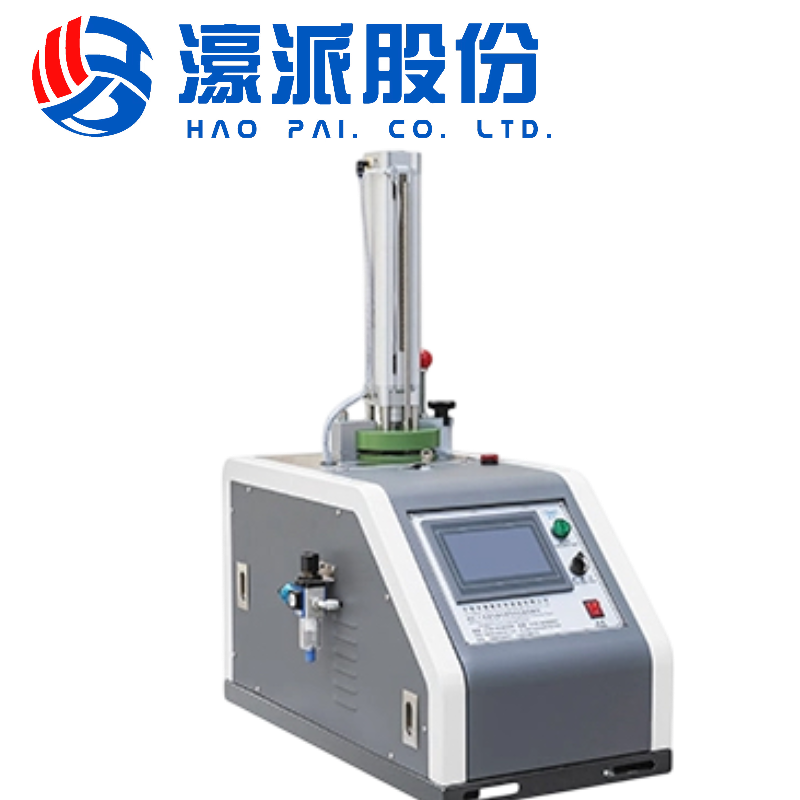

Powerful capacity and efficient performance

(1) Large capacity design

The 2.5p PUR Hot Melt Glue Machine is equipped with a convenient 2.5kg capacity glue bucket that can hold a sufficient amount of PUR (polyurethane reactive) polyurethane reactive hot melt adhesive. This high-capacity design eliminates the need for frequent glue replenishment during the production process, effectively reducing downtime. It is particularly suitable for production environments that require long-term continuous operation, greatly improving overall production efficiency. Whether it is large-scale industrial production or small-scale, multi batch precision operations, this machine can ensure the smooth progress of the production process with its excellent capacity performance.

(2) Efficient operation mechanism

Fast heating: The machine has a fast heating function, which can quickly heat PUR hot melt adhesive from room temperature to the appropriate working temperature. This feature not only saves time waiting for the glue to melt, but also enables the equipment to be quickly put into production, meeting the needs of enterprises with high production rhythm requirements. In some industries that are extremely sensitive to order delivery time, such as electronic product manufacturing and packaging, the rapid heating function can help companies seize business opportunities and complete order tasks in a timely manner.

Basic Info.

Product Description

1.High strength integrated melting glue goove, radiated heating pieces, increase heat transmission area, and glue melting rate.

2.The temperature control system is displayed by touchscreen, featured with even heating and no easy to be carbonized.

3.Special design of gear pump with large releasing amount, with stable glue discharging.

4.Built-out independent suspending system of gear pump to facilitate the repairing and save time.

5.Full open flow amount control valve, which can obtain the highest efficiency of glue pumping.

6.Modular design, which is easy to change different model of gear pump or reflow valve.

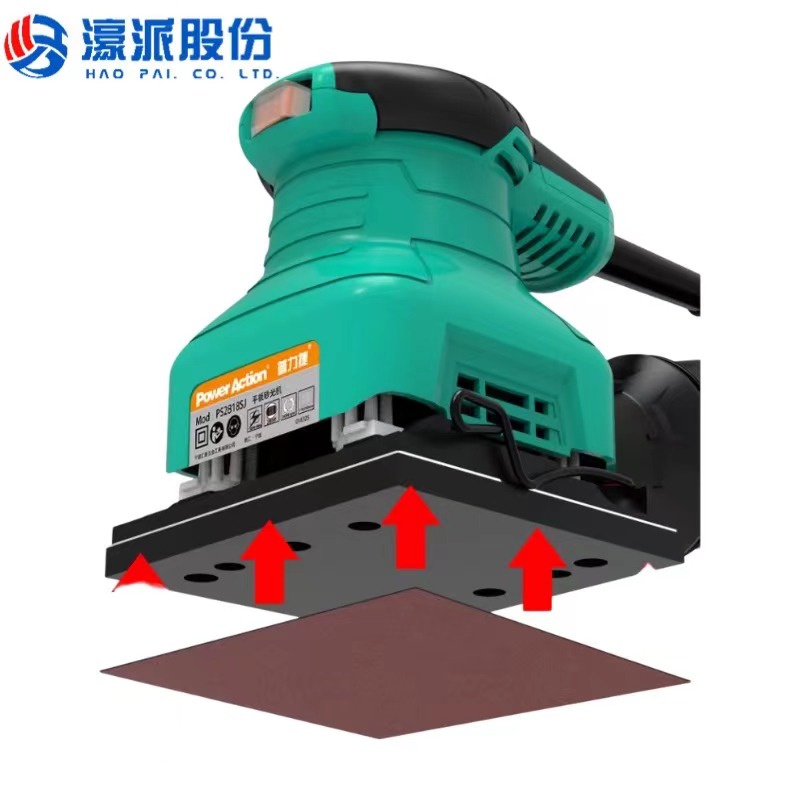

Application scope: Wood coating fitting, textiles lamination, PET transparent boxes, auto inner decoration pieces, bookbinding, household appliance assembly etc.

| System | Speed control AC motor gear pump |

| Barrel diameter | ¢128mm |

| Maximum glue supply amount | 3kg/H |

| 3kg/H | 1(2)1 line (or 2lines) |

| Maximum working pressure | 8.5Mpa |

| Operating temperature scope | 40-250ºC |

| IEnvironment temperature scope I | -20-50ºC |

| Temperature control precision | ±1ºC |

| Temperature sensor | Pt100 |

| Power supply | 220V |

| Maximum system power | 3.7KW |

| Air pressure applied | 0.5~0.8Mpa |

| Weight | 80kg |

| Connection signal | 2input,2output |

| Installation size | 750mm*400mm*940mm |

| Level of prevention | IP54 |