Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

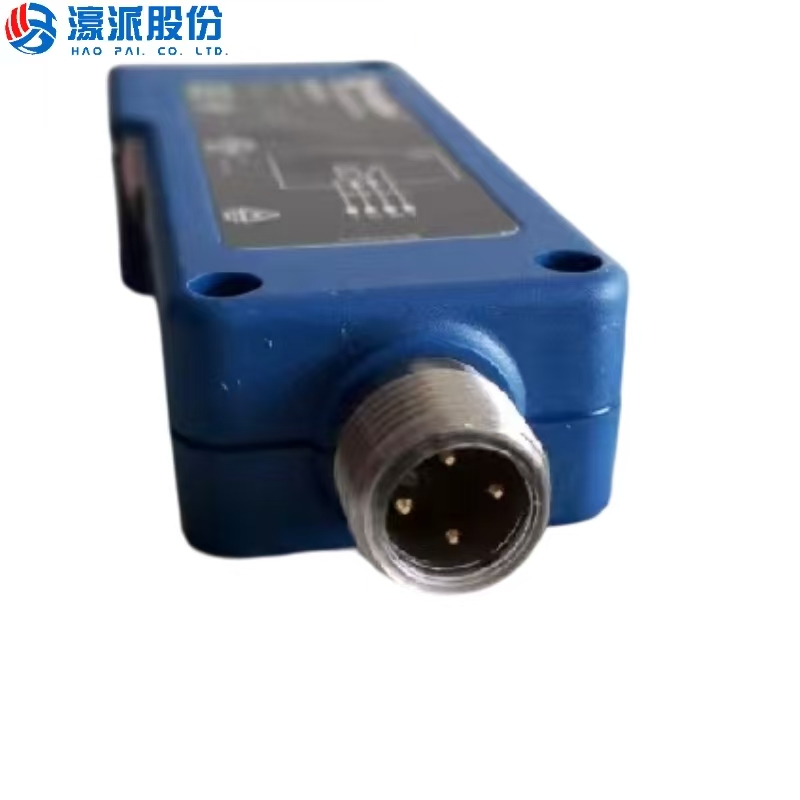

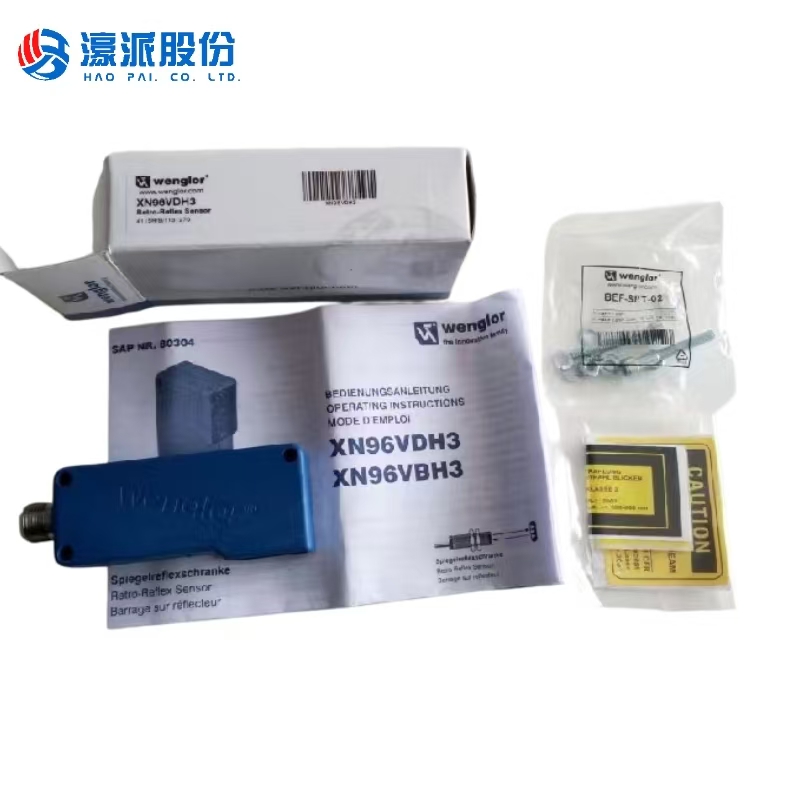

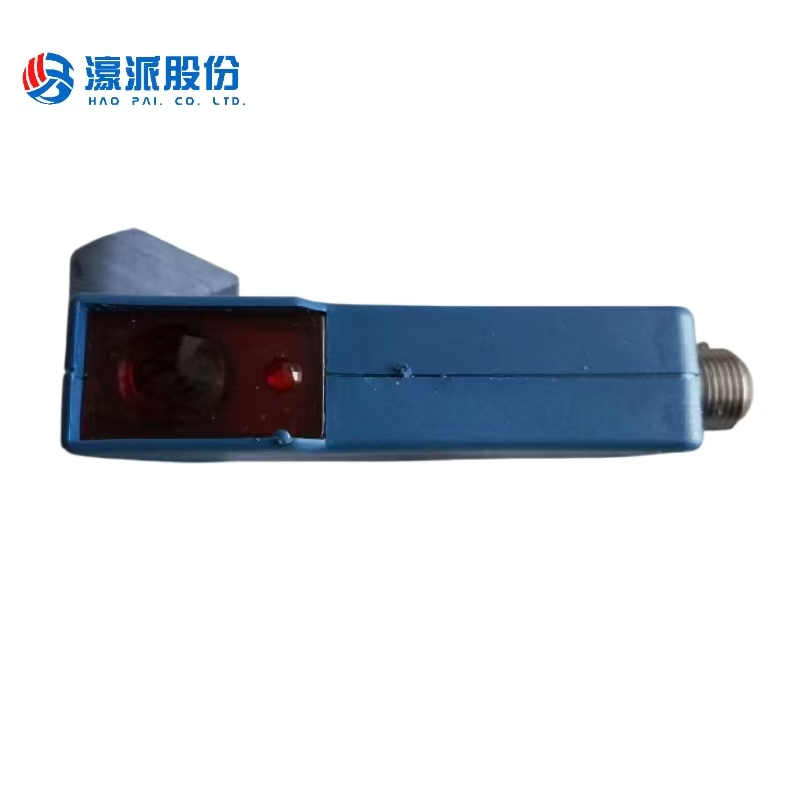

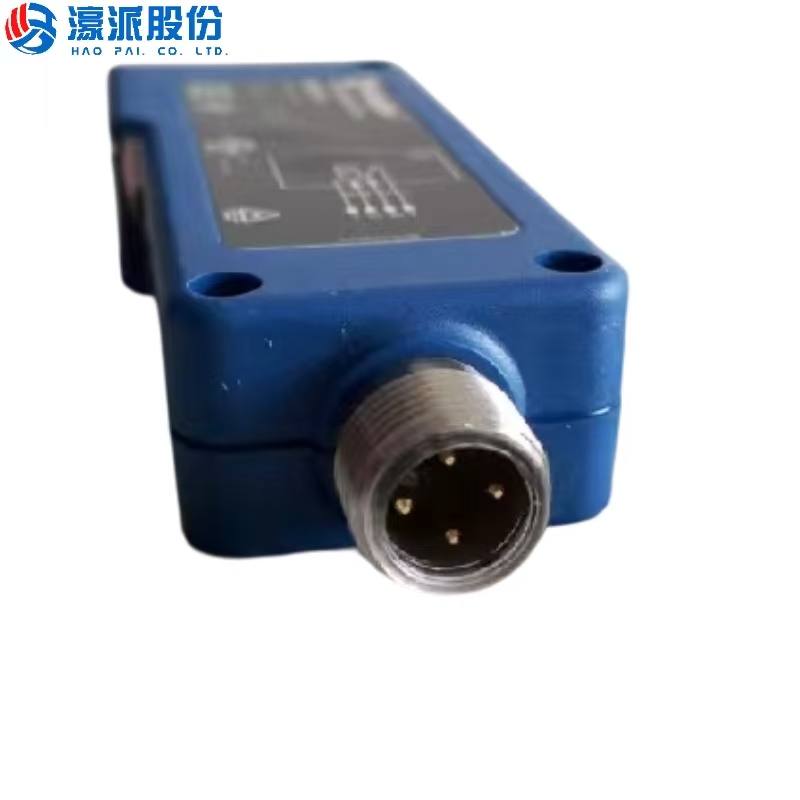

Homag Woodworking Machinery Spare Part Reflecting Light Barrier-2

- WENGLOR

- CHINA

- 5-10days

- 100PC/MONTH

- XN96VDH3

Product Advantages and Features

1.High Precision

WENGLOR sensors are renowned for their high precision in detecting and measuring various physical quantities. They can accurately capture and transmit data, ensuring reliable results in different application scenarios. For example, their optical sensors can precisely identify the position and shape of objects with minimal errors.

2.Durable and Robust Construction

These sensors are built with sturdy materials and advanced manufacturing techniques, enabling them to withstand harsh industrial environments. They have excellent resistance to shock, vibration, dust, and moisture, which means they can maintain stable performance over a long period even in tough working conditions.

3.Versatile Detection Capabilities

WENGLOR offers a wide range of sensors with diverse detection principles, such as photoelectric, inductive, capacitive, and ultrasonic detection. This versatility allows them to be applied to detect different types of objects, whether they are solid, liquid, or gaseous substances, and can handle various industrial processes like object positioning, level measurement, and flow monitoring.

4.Easy Integration

With standardized interfaces and compatibility with common industrial control systems, WENGLOR sensors can be easily integrated into existing production lines or automation systems. Their installation and configuration are straightforward, saving time and effort for engineers during the setup process.

5.Compact Design

Many of the WENGLOR sensors feature a compact size, which is convenient for installation in space-limited areas. Their small footprint doesn't sacrifice performance but instead makes them suitable for applications where space is at a premium, such as in cramped machinery compartments or on small production units.

Product Technical Parameters

Parameter | Details |

Model | XN96VDH3 |

Sensor Category | Photoelectric sensor (typical for WENGLOR) |

Operating Voltage | 10 - 30 V DC |

Output Type | Digital output (NPN/PNP, typical) |

Detection Range | Up to several meters (application - specific) |

Protection Class | IP67 (common for industrial use) |

Operating Temperature | -25°C to +55°C (typical range) |

Product Application Scope

Industrial Manufacturing

In industrial production lines, WENGLOR sensors are widely used for various purposes. For example, photoelectric sensors can be applied to detect the presence or absence of workpieces on conveyor belts, helping to control the production process and ensure the correct operation sequence. Inductive sensors are excellent for identifying metal parts during assembly processes, enabling precise positioning and efficient manufacturing.

Automotive Manufacturing

In the automotive industry, WENGLOR sensors are employed in multiple aspects. For instance, they can be used to detect the position of car parts during the assembly process, like ensuring that doors are properly aligned and installed. Additionally, sensors can monitor the movement of robotic arms in the production line to achieve accurate and efficient manufacturing operations.

Product Description

Advantage and Feature | Description |

High Precision Detection | It is capable of precisely detecting objects within its specified detection range, ensuring accurate recognition and measurement with minimal errors. |

Robust Construction | Built with durable materials, it can withstand harsh industrial environments, including resistance to shock, vibration, and exposure to dust, moisture, etc. |

Versatile Detection Modes | Supports multiple detection modes (depending on its specific design), enabling it to adapt to different types of target objects and application scenarios, whether for detecting solid objects, monitoring positions, or identifying movements. |

Fast Response Time | Has a relatively short response time, typically within [specific time value, e.g., milliseconds], allowing it to quickly react to changes in the detected environment and promptly output corresponding signals. |

Excellent Compatibility | Can be easily integrated with various industrial control systems, thanks to its standardized interfaces and compatibility with common communication protocols, facilitating seamless connection in automated production lines. |

Compact Design | Its compact size makes it convenient for installation in space-limited areas, such as in narrow machinery compartments or on densely arranged production equipment without taking up excessive space. |

High Sensitivity | Exhibits high sensitivity to the physical parameters or object characteristics it is designed to detect, enabling it to sense even slight changes or the presence of small objects effectively. |

Reliable Performance | Consistently delivers reliable performance over an extended period, with stable operation under normal operating conditions and a low failure rate, reducing maintenance costs and downtime. |

Adjustable Settings | Offers certain adjustable parameters (like detection distance thresholds, output signal formats, etc.), allowing users to customize it according to specific application requirements for optimal performance. |

The XN96VDH3 WENGLOR sensor has multiple advantages including high precision detection, robust construction, fast response time, excellent compatibility, compact design, high sensitivity, reliable performance and adjustable settings, making it suitable for various industrial applications.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.