Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

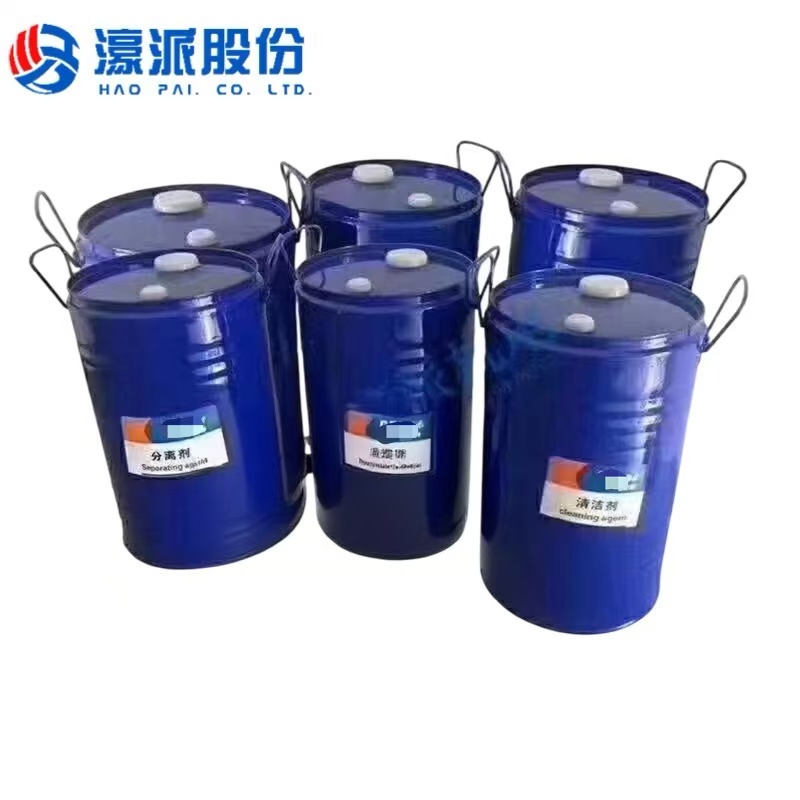

Traditional hydrocarbon cleaning agent

- Reynolds

- British brand

- 7-15 days

- 30 per month

- 30L

- 30L

Product Advantages and Features

1.Compatibility and Security

Broad-spectrum compatibility: By optimizing surfactants and buffers (including glycerol, ethylene glycol butyl ether, etc.), it is compatible with metals, plastics, and precision electronic components, with a surface tension of ≤28mN/m and a neutral pH value (6.5-7.5) to avoid corrosion risks. Biological safety: Free of DNAse, RNase, and pyrogens, meeting medical device cleaning standards and ensuring zero pollution risk in the experimental environment.

2.Optimization of cleaning efficiency

Multi-scenario application: Supports spray, ultrasonic, and immersion cleaning, effectively removing oil stains, biological residues, and nozzle blockages

Filter protection design: The filter-type product effectively prevents cross-contamination between the sample and the pipette, enhancing the safety of sample aspiration

3.Production and supply guarantee

Precision Manufacturing: Produced in a Class 100,000 clean room, with stable batch quality, we offer a wide range of specifications in stock from 10μL to 1000μL.

Economic benefits: Large-capacity packaging (such as 5000ml) reduces the cost per use to 0.1 yuan/ml, accommodating high-frequency maintenance needs

Product Technical Parameters

Scene | Cleaning Effect | Technical Support |

Nozzle Blockage Removal | Blockage removal rate >95%Drying time <3 minutes | Low surface tension(s28mN/m)improves permeability |

Biological Contamination Control | No DNA enzyme/RNA enzymeresidue, Meeting thesterilization standard formedical device low- temperature sterilization | Biodegradability meets OECD301B standard |

Metal Equipment Protection | Ainum corrosion loss≤0.03g/m? Copper corrosionloss s0.08g/m? | BTA + TTA + Molybdate composite corrosion inhibition system |

Heavy Oil Stain Decomposition | At 70 - 80°C, Dirt removalefficiency improved by 40% under working conditions | Synergistic effect of emulsifierand dispersant |

Product Application Scope

Production and supply guarantee

1. Core applicable scenarios

Precision instrument maintenance

Printing equipment nozzle cleaning: Efficiently removes pigment condensation residue, restores inkjet precision, and is compatible with mainstream inkjet systems such as Epson and Canon.

Medical analysis equipment pipeline cleaning: The filter cartridge can prevent cross-contamination of the pipette, eliminate residual biological samples, and ensure detection accuracy.

Metal processing equipment maintenance: quickly decompose industrial oil stains such as cutting oil and rust preventive oil, extending the lifespan of gearboxes, compressors, and other precision components.

High-sensitivity material cleaning

Electronic component cleaning: The neutral formula (pH 6.5-7.5) poses no corrosion to PCB boards and sensors, effectively removing dust and flux residues.

Optical lenses and 3C products: Achieving the removal of particles down to 0.1μm level, thereby enhancing the yield rate of coating to 99.3%5.

Industrial heavy oil contamination treatment

Supports ultrasonic/immersion cleaning, capable of decomposing a 3mm oil and dirt layer at room temperature within 5-15 minutes, with an annual corrosion rate of less than 0.1mm for carbon steel.

II. Key performance advantages

SceneCleaning EffectTechnical Support

Nozzle blockage removal: Blockage removal rate >95%, drying time <3 minutes. Low surface tension (≤28mN/m) enhances permeability

Biological pollution control: Free of DNAse/RNase residue, meeting medical device sterilization standards. Biodegradability meets OECD 301B standard

Metal equipment protection: Corrosion amount of aluminum material ≤ 0.03g/m², copper material ≤ 0.08g/m²; BTA+TTA+molybdate composite corrosion inhibition system5

Heavy oil stain decomposition: Decontamination efficiency is increased by 40% under working conditions of 70-80℃. Emulsifier and dispersant synergize.4

III. Comparison with traditional solvents

Efficiency improvement: The cleaning rate of the water-based formula at low temperature (45°C) reaches 97%, with a time reduction of 67% compared to solvent-based products.

Cost optimization: The cost per single use for large packaging (5000ml) is as low as 0.1 yuan/ml, reducing waste liquid disposal costs by 60%.

"Safety breakthrough": Non-combustible design to avoid combustion and explosion risks, supporting live operation; no halogen/benzene series/VOC emissions

Product Description

| Advantage | Traditional drilling method | CNC drilling |

| Accuracy | ± 1mm or more, relying on worker experience | 0.1mm, CNC controlled |

| Efficiency | Single hole drilling one by one, slow speed | Synchronized processing with multiple drill bits increases efficiency by 5-10 times |

| Flexibility | Changing production requires adjusting molds, which is time-consuming | One click program switching to adapt to different products |

| Labor cost | Requires skilled workers, high training costs | Automated operations reduce the skill requirements for workers |

| Quality stability | Easy to miss or misplace drilling | The system automatically detects to ensure the pass rate |

In the fiercely competitive woodworking manufacturing industry, CNC drilling is your best choice to improve efficiency, reduce costs, and ensure quality! Choosing CNC drilling is choosing an efficient, precise, and worry free production method! Whether it's panel furniture, cabinets, wooden doors, or whole house customization, it can help you seize market opportunities and win customer trust!

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.