Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

Protean CNC Drilling Head Milling Woodworking Boring Head-9

- Puden

- Guangdong, China

- 15days

- 20 a month

- PD-cnc A9B3C1

- 180mm×150mm×120mm

Product Advantages and Features

1、Super long durability.

Core components are made of hardened alloy material, and the surface of the drill holder is nitrided, with a hardness of HRC58-62. Under normal working conditions, the service life is more than 50% longer than that of ordinary drill heads.

2、Low energy consumption design.

The motor power matching is optimized, the power consumption during no-load operation is reduced to below 80W, and the energy consumption during full-load processing is 15%-20% less than that of similar products, which can significantly save electricity costs in long-term use.

3、Humanized operation experience.

Equipped with a 7-inch touch screen, the interface supports Chinese and English switching, and the operation steps are guided by visualization. Novices can master basic operations in only 30 minutes. At the same time, a custom shortcut key function is reserved, allowing skilled workers to call common processing parameters with one key.

4、Comprehensive safety protection.

Built-in overload protection system, which automatically stops when the processing resistance exceeds the set threshold (default 80N); the drill head cover is made of transparent explosion-proof PC material, which not only does not affect processing observation, but also prevents iron chips from splashing and hurting people.

Product Technical Parameters

1 | Applicable plate thickness | 15–80 mm |

2 | Maximum drilling diameter | φ12–φ50 mm |

3 | Spindle speed range | 120–560 r/min |

4 | Spindle motor power | 5.5 kW |

5 | Table size | 1600×3000 mm |

6 | Maximum positioning speed | 8000 mm/min |

7 | Number of tool holders | 3 |

8 | Lubrication method | Automatic Power-Off Protection |

Product Application Scope

1、Wooden materials.

It is compatible with solid wood panels, particle boards, MDF (Medium Density Fiberboard), and multi-layer solid wood boards. It can stably process wooden workpieces with a thickness of 5-50mm, meeting the drilling needs of the furniture industry.

2、Plate materials.

It supports PVC boards, acrylic boards, and thin aluminum-plastic composite boards (thickness ≤10mm). It can avoid material cracking or rough edges during drilling, adapting to decorative building material processing scenarios.

3、Metal thin plates.

It can process cold-rolled steel plates and galvanized steel plates with a thickness of 1-6mm. When matched with a dedicated metal drill bit, it can ensure hole position accuracy without damaging the plate surface, suitable for hardware accessory production.

4、Furniture manufacturing industry.

It is used for drilling side panels and top panels of panel furniture such as wardrobes, cabinets, and bookcases. It can complete the processing of multiple types of holes including hinge holes, connection holes, and positioning holes, adapting to mass production lines.

5、Custom home furnishing industry.

It supports the processing of custom-sized home workpieces, such as special-shaped holes (non-standard hole diameters or distances) of custom dressers and entrance cabinets, and can flexibly match the custom parameters of the panel splitting software.

6、Decorative building materials industry.

It is used for processing installation holes of decorative panels, ceiling panels, and partition panels, adapting to scenarios requiring high hole position consistency in engineering decoration, such as hotel and office building decoration projects.

Product Description

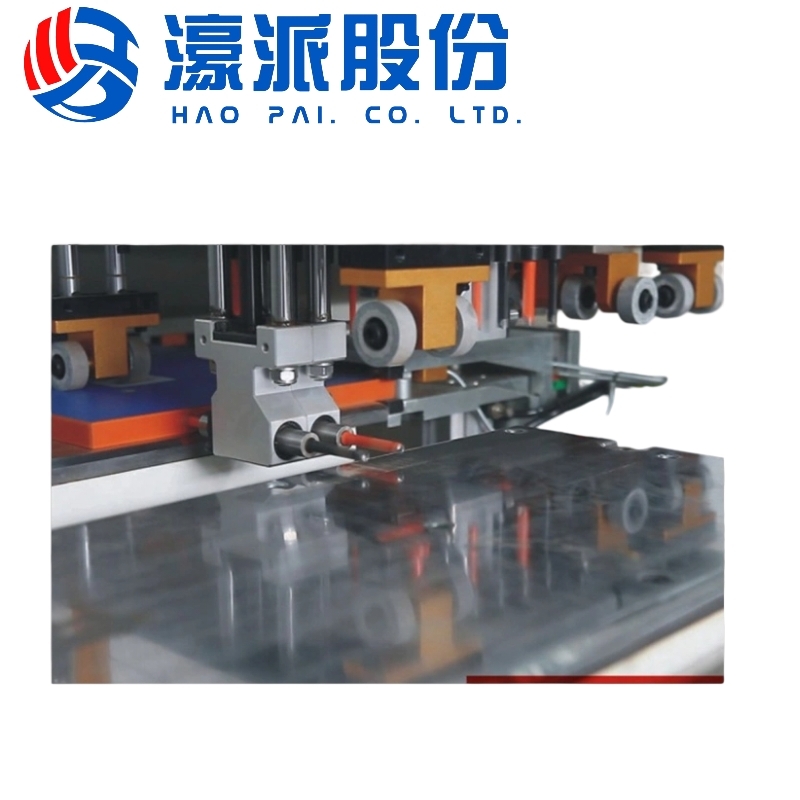

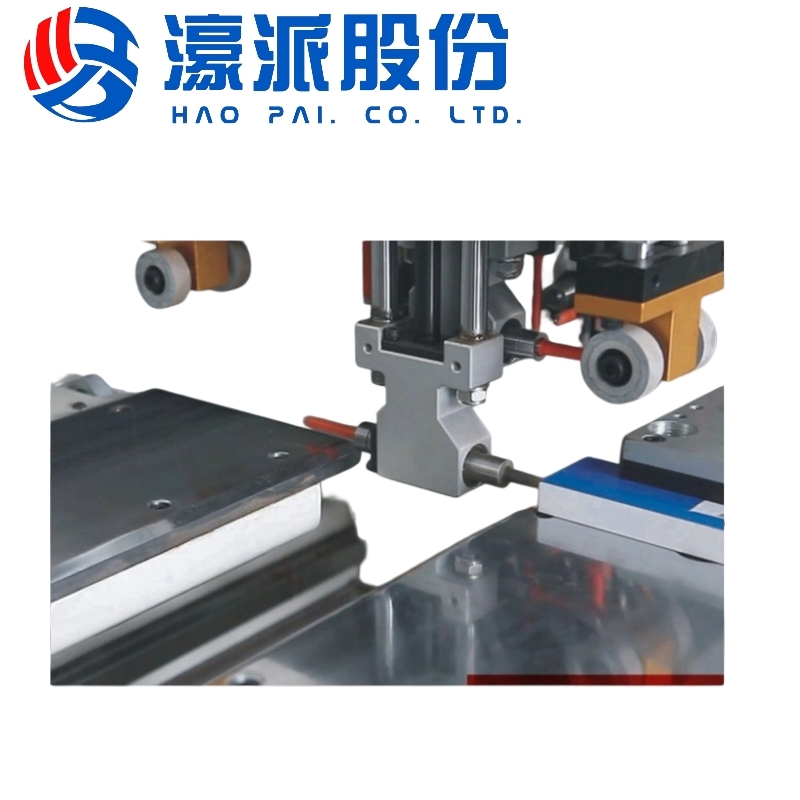

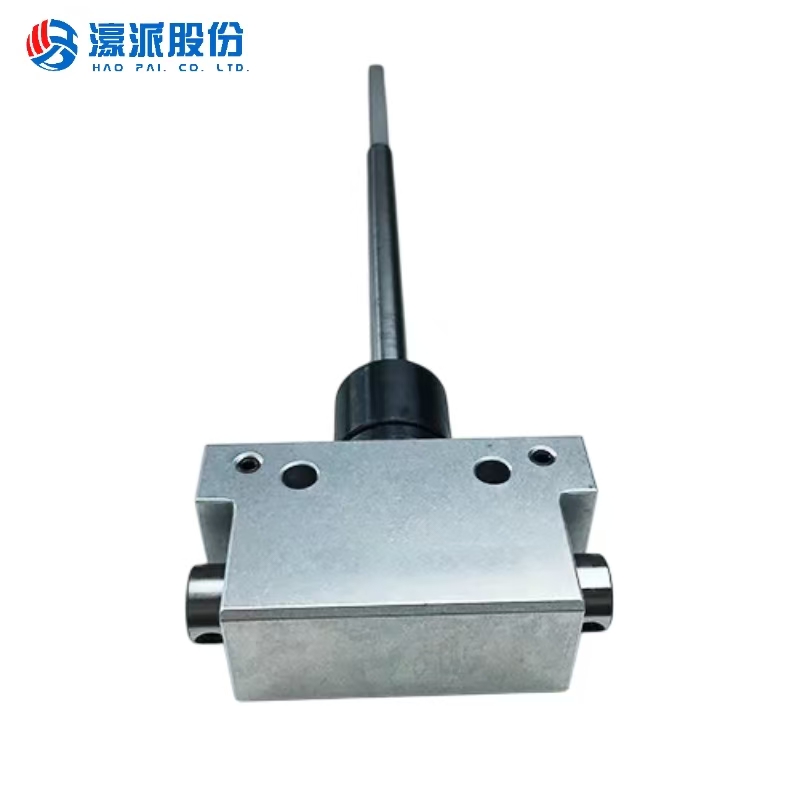

1、Transmission system

Adopts double ball screw transmission, matched with a servo motor (power 0.75KW), with a transmission gap ≤0.02mm to ensure precise movement of the hole position without deviation; the drill holder is a 3-jaw self-centering structure, compatible with drill bits of φ3-16mm specification, with a clamping force of up to 500N to prevent the drill bit from slipping during drilling.

2、Control unit:

Built-in independent CNC module, supporting G-code and M-code programming, which can be seamlessly connected with the PLC control system; equipped with a temperature sensor to monitor the motor temperature in real time (warning threshold 85℃), and automatically trigger frequency reduction protection when the temperature exceeds the limit.

3、Appearance and dimensions:

The whole body adopts a die-cast aluminum alloy shell, and the surface is treated with anodization (color is industrial gray); the overall dimensions are 280mm×160mm×220mm (length × width × height), with a net weight of 12.5kg, which is convenient for equipment installation and space adaptation.

4、Drilling precision

Positioning accuracy ±0.05mm, repeat positioning accuracy ±0.03mm, capable of processing equidistant hole groups with a hole pitch error ≤0.1mm, meeting high-precision needs such as furniture hinge holes and hardware accessory fixing holes.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.