Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

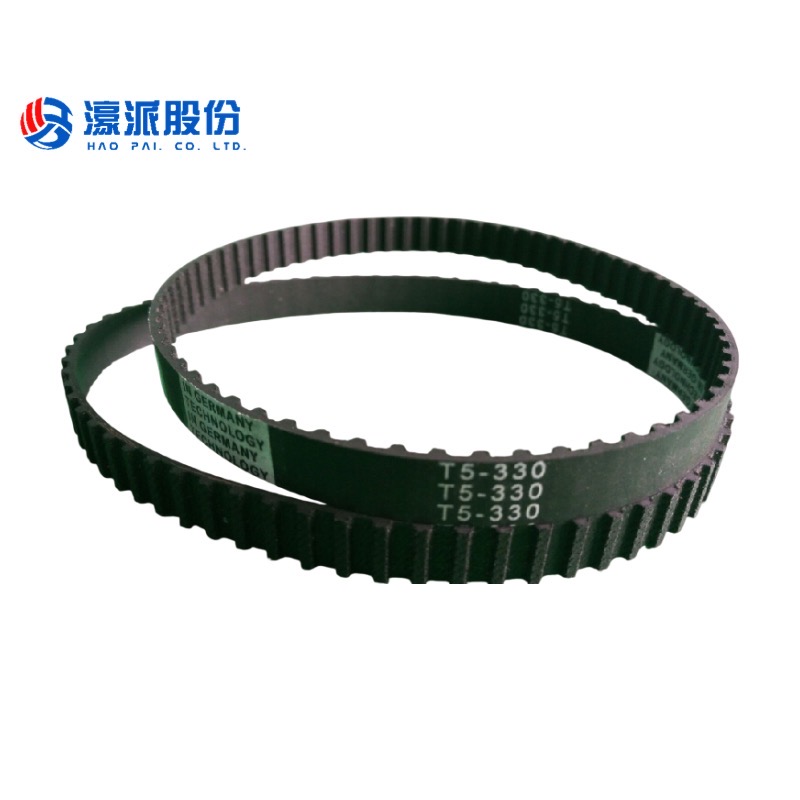

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

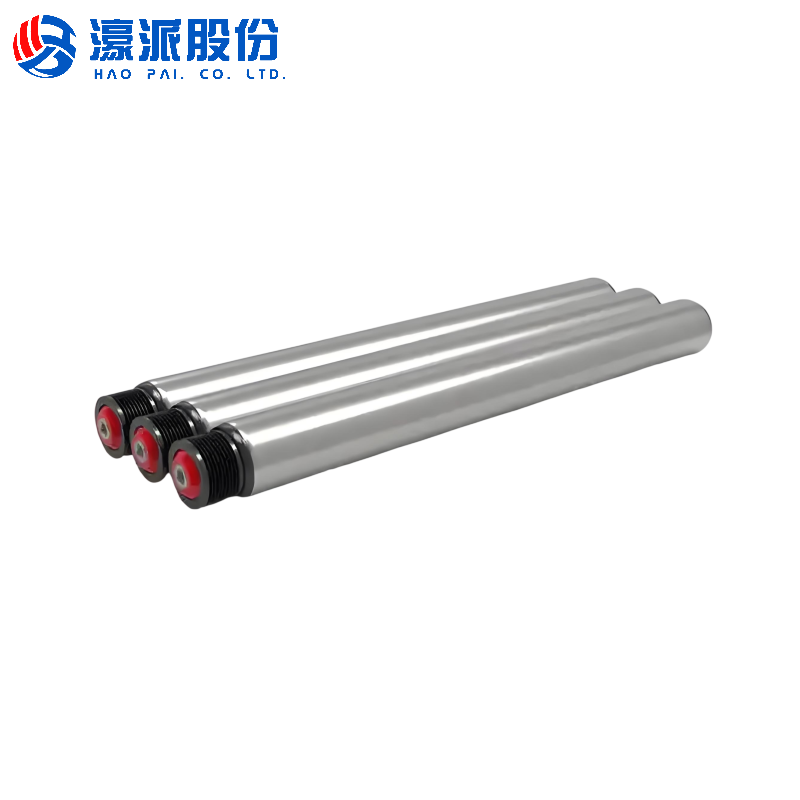

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

Roller Conveyor Motors

- TCG

- Guangdong,China

- 10-15 days

- 5 units

- TC8024-0.75KW-B3

Product Advantages and Features

1.Compact Size

The product features a compact design, occupying little space. It can be easily installed in limited mounting spaces, well meeting the requirements of equipment and occasions with high space constraints, and facilitating the miniaturization design of equipment.

2.Low Noise and Vibration

It generates extremely low noise and minimal vibration during operation, providing a quiet and stable running environment for the equipment. This not only helps improve the comfort of the working environment but also reduces wear and impact on other parts of the equipment caused by vibration, extending the overall service life of the equipment.

3.High Torque Output

It has high torque, enabling strong power output to drive heavy loads. It is suitable for occasions requiring large driving power, ensuring stable operation of the equipment.

4.Wide Speed Range

TIt boasts powerful speed change functionality and a wide speed range. It can easily adjust to different rotational speeds according to various work requirements, meeting multiple working conditions and enhancing the motor's appli

cability and flexibility.

5.Excellent Heat Dissipation

With a reasonable heat dissipation design, it has a good heat dissipation effect. It can effectively dissipate the heat generated during motor operation, avoiding performance degradation or failures caused by overheating, which helps maintain stable operation of the motor and prolong its service life.

Product Technical Parameters

| Brand | Model | Protection Level | F |

| TCG | TC8024-0.75KW-B3 | Power | 0.75KW |

| Rated Voltage | 380/220V | Current | 1.97/3.41A |

| Rotational Speed | 1400/1680 | Frequency | 50HZ |

Product Application Scope

| Comparison Items | TCG Motor (Gear Reduction Motor) | DC Brushed Motor | DC Brushless Motor | AC Induction Motor | AC Permanent Magnet Synchronous Motor |

| Structure | Integrated design of motor and reduction mechanism, compact structure | Composed of stator, rotor, brushes, and commutator | Consists of stator, rotor, and electronic controller | Composed of stator and rotor | Rotor embedded with permanent magnets, stator windings energized to generate magnetic field |

| Power Range | Commonly used in small-to-medium power applications | Generally low power | Wide power range | Large power range | Commonly used in medium-to-high power applications |

| Speed Regulation | Variable speed via speed regulating motor or frequency converter, wide speed range | Relatively simple and convenient speed control | Excellent speed regulation, precise control via electronic controller | Poor speed regulation, usually requires frequency converter | Good speed regulation, high-precision control achievable |

| Starting Torque | High starting torque, provides strong torsion | High starting torque | High starting torque | Relatively low starting torque | High starting torque, rapid startup |

| Lifespan | Long lifespan, good insulation, stable performance | Brushes prone to wear, shorter lifespan | No brush wear, long lifespan | Long lifespan, but may be affected under complex conditions (e.g., frequent startups) | Long lifespan, but permanent magnets may demagnetize under high temperatures |

| Maintenance Cost | Simple maintenance, no frequent upkeep required for reduction mechanism and motor body | Regular brush replacement needed, high maintenance cost | Minimal maintenance, periodic checks of electronic controller only | Low maintenance cost, mainly periodic stator/rotor inspections | Generally low maintenance, high repair cost if demagnetization occurs |

| Cost | Moderate overall cost (higher than standard motors due to reduction mechanism) | Low cost | Relatively high cost (due to electronic controller) | Low cost, high cost-performance ratio for high-power applications | High cost (due to rare earth permanent magnet materials) |

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.