Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

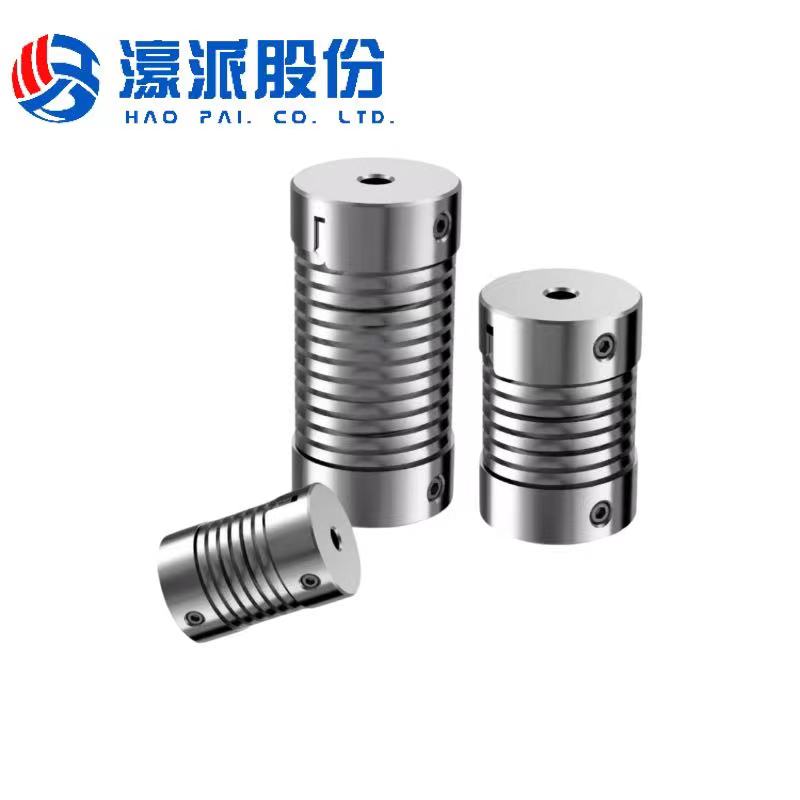

Spring-coupling eccentricity-angle encoder coupling

- Haopai

- Made in China

- 5-7days

- 100 pcs month

- 16*25

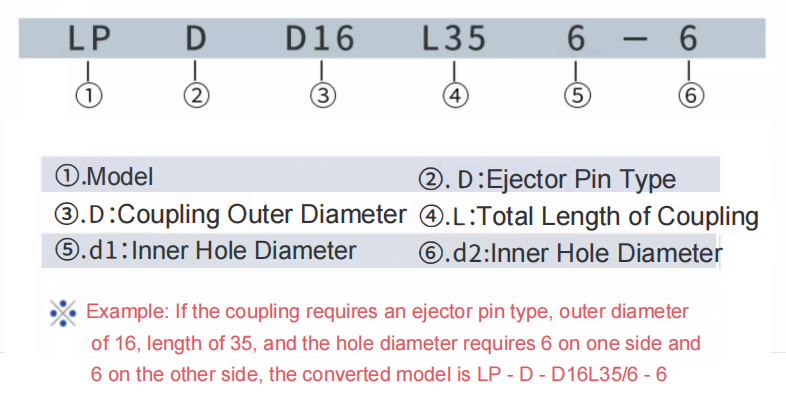

- LP-D-D16L25

Product Advantages and Features

1.High-precision torque transmission: It can usually achieve zero rotational backlash and accurately transmit torque, ensuring the operational accuracy of equipment such as stepping motors, enabling the system to run synchronously. It is suitable for occasions with high requirements for position accuracy, such as precision machining equipment and automated production lines.

2.Excellent eccentricity and deflection angle compensation capability: It has excellent flexibility. Its elastic thread design or special spring structure can effectively compensate for radial, angular and axial deviations when connecting equipment such as motors and encoders, allowing a certain degree of eccentricity and deflection angle. This reduces the impact of installation errors or deviations generated during equipment operation on the equipment and protects the equipment from additional stress damage.

3.Shock absorption and noise reduction: It can absorb vibrations generated during equipment operation, reduce the impact of vibrations on the system, make power transmission smoother, and reduce noise at the same time, creating a relatively quiet working environment. This is not only conducive to the stable operation of the equipment but also prolongs the service life of equipment components. It is often used in occasions with high requirements for operational stability and noise, such as optical equipment and medical equipment.

4.High torque carrying capacity: Some products are made of high-strength materials and undergo special technological treatments, such as shot peening of springs. This enables them to have high torque carrying capacity, which can meet the application needs of small motors and stepping motors that need to transmit large torques, adapting to various working loads.

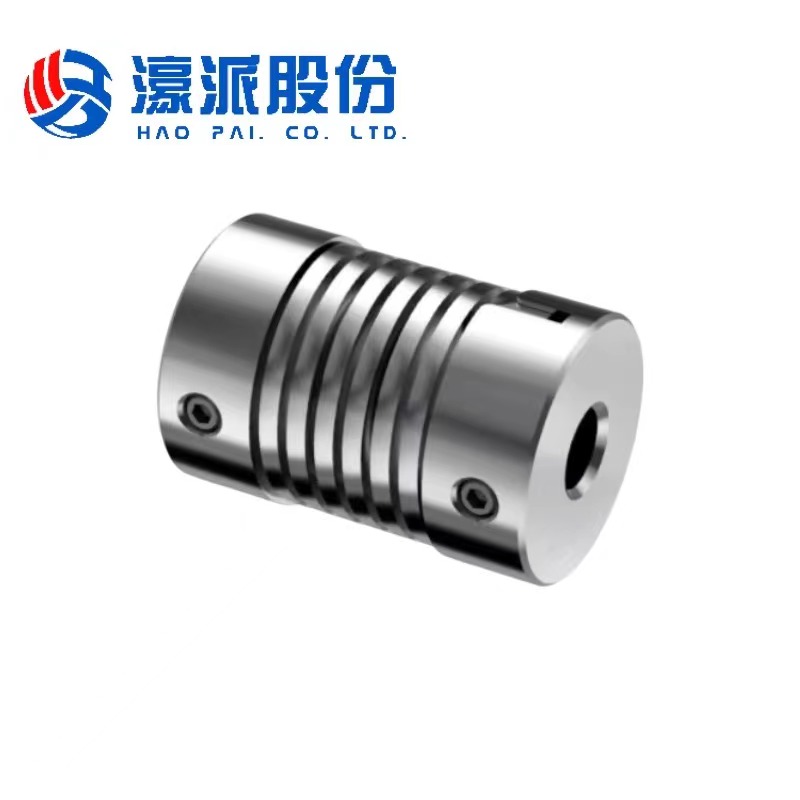

5.Compact and lightweight structure: Generally, it has a small volume and light weight, occupies little space, and is convenient to install in equipment with limited space. It will not bring too much burden to the overall structure of the equipment, and is especially suitable for miniaturized and precision mechanical equipment, such as small robots and portable instruments.

6.Easy installation and maintenance: The installation method is relatively simple. Some can be installed in a plug-in manner after the shafts are aligned, and there is no need for frequent maintenance. It has oil resistance, corrosion resistance and other characteristics, and can maintain stable performance in relatively harsh working environments, reducing the use cost and maintenance workload.

7.Long service life: It is made of high-quality materials such as high-strength alloy steel, undergoes heat treatment processes such as quenching and tempering, and is supplemented by surface shot peening treatment, which can enhance the fatigue strength of the material, improve the service life of the coupling, reduce the replacement frequency, and lower the long-term operation cost of the equipment.

Product Technical Parameters

Product Material | Zinc Alloy | Configured Screws | Grade 12.9 Screws |

Surface Treatment | Anodic Surface Oxidation Treatment | Product Temperature | -40°C ~ 100°C |

Regarding Customization | Please contact customer service to confirm the delivery time for customized items |

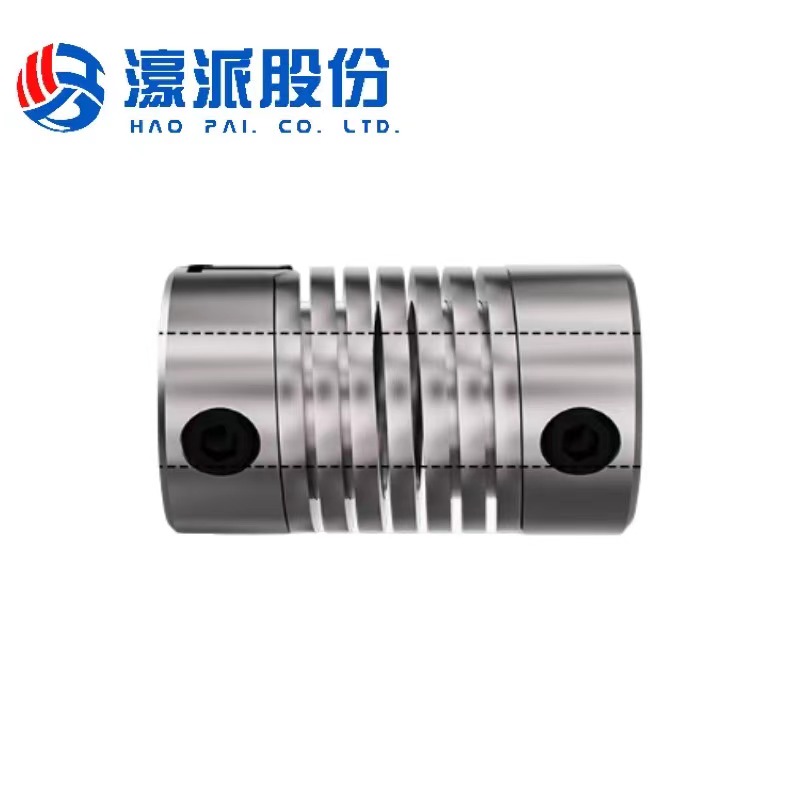

Dimension Comparison Table

Model | D (mm) | L (mm) | d1—d2 (Min Bore—Max Bore) | Installed Screws (M) | L1 (mm) | L2 (mm) | Screw Tightening Torque (N.m) |

LP - D - D16L25 | 16 | 25 | 4—10 | M4 | 4 | 13 | 4.9 |

LP - D - D16L35 | 16 | 35 | 4—10 | M4 | 4 | 13 | 4.9 |

LP - D - D26L38 | 26 | 38 | 5—16 | M5 | 6 | 18 | 10 |

LP - D - D26L50 | 26 | 50 | 5—16 | M5 | 6 | 18 | 10 |

Product Application Scope

Industrial Automation Field

· Automated production lines: In automated production lines for electronics, auto parts, etc., equipment requires precise position control and stable power transmission. This type of coupling can connect stepper motors with transmission mechanisms to achieve high-precision torque transmission, ensuring that robotic arms accurately grasp and place parts, as well as the stable operation of conveyor belts, thereby improving production efficiency and product quality.

· CNC machine tools: Used to connect motors with components such as lead screws and gearboxes, it compensates for eccentricity and deflection angles caused by installation errors, ensures the movement accuracy of tools or worktables, and enables precision machining of complex parts.

Electronic Equipment Manufacturing Field

· Semiconductor manufacturing equipment: Equipment such as lithography machines and wafer cutting machines have extremely high requirements for motion accuracy and stability. This coupling can effectively absorb shocks and reduce noise, minimize the impact of vibrations on precision optical and mechanical components, and meet the demand for nanoscale precision in semiconductor manufacturing processes.

· 3D printers: It connects the motor with the transmission mechanism of the print head, precisely transmits torque during printing, enables the print head to move accurately according to the designed path, ensures the precision and quality of the printed model, and at the same time absorbs vibrations generated during printing to ensure stable operation of the equipment.

Intelligent Robotics Field

· Service robots: Such as household cleaning robots and welcome robots, this coupling connects motors with components such as drive wheels and robotic arms to achieve flexible motion control. Meanwhile, its compact and lightweight structure does not bring excessive burden to the overall design of the robot.

· Industrial robots: In industrial robots such as palletizing robots and welding robots, it is used to connect motors with joints, ensuring that the robots can accurately perform actions during repeated operations, improving production efficiency and product quality. In addition, its excellent shock absorption and noise reduction performance helps reduce the noise generated when the robots are running.

Scientific Research and Experimental Equipment Field

· High-precision testing instruments: In instruments such as material mechanical property testing equipment and optical experimental platforms, the coupling connects the motor with the testing device, ensuring the stability and accuracy of power transmission during testing, and providing a guarantee for the accuracy of experimental data.

Product Description

Model | Rated Torque | Torque Upper Limit | Maximum Rotational Speed(r/min) | Moment of Inertia(kg.m²) | Allowable Eccentricity(mm) | Allowable Deflection Angle(°) | Weight(g) |

LP - D -D16L25 | 0.3 | 0.6 | 3000 | 2.5×10⁻⁷ | 1 | 5 | 24 |

LP - D - D16L35 | 0.25 | 0.5 | 3000 | 5.8×10⁻⁷ | 2 | 6 | 29 |

LP - D - D26L38 | 0.6 | 1.2 | 3000 | 1.8×10⁻⁶ | 1.5 | 6 | 64 |

LP - D - D26L50 | 0.45 | 0.9 | 3000 | 4.7×10⁻⁶ | 2.5 | 10 | 89 |

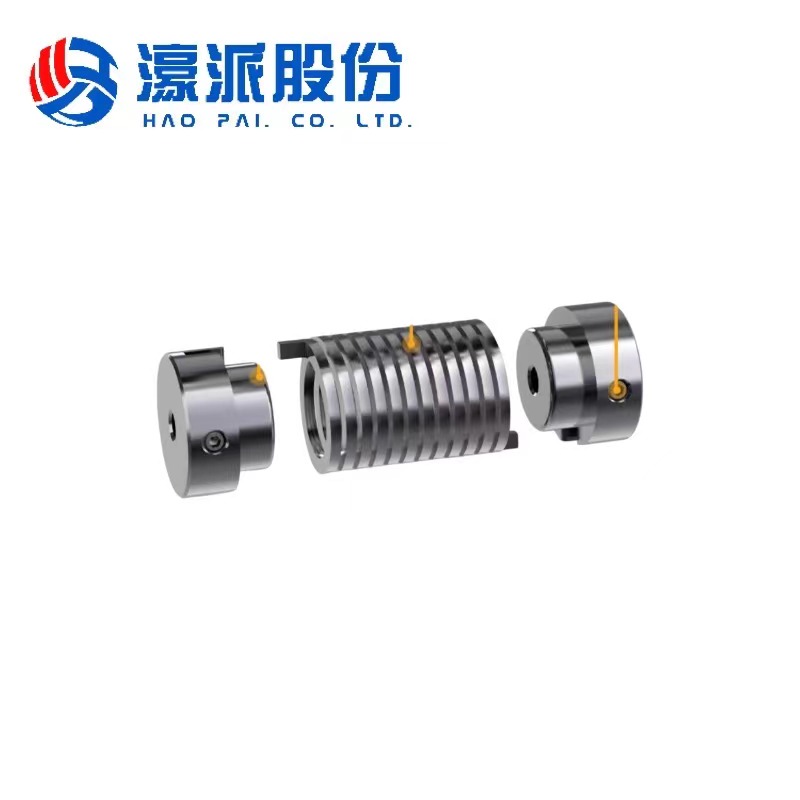

This spring coupling is a core component for achieving efficient and precise connection between small motors, elastic stepper motors, encoders and other equipment. With its excellent design and performance, it has become an ideal choice in the field of power transmission.

Its innovative integrated elastic structure is a major highlight. The core spring component is cleverly combined with the flexible thread layout to form a unique flexible transmission system. This design not only enables precise torque transmission to ensure no deviation in power transmission, but also can easily resolve radial, angular and axial deviations during equipment connection through its own elastic deformation. It effectively copes with eccentricity and deflection angle problems caused by installation errors or operation, providing a solid guarantee for the stable power connection of the equipment.

In terms of material selection, the product adheres to high-quality standards and adopts high-quality materials such as high-strength alloy steel. After multiple strict heat treatment processes such as quenching and tempering, the structural strength is greatly enhanced; the surface is further subjected to shot peening treatment to improve the fatigue resistance of the material, ensuring that the product can still maintain stable and reliable performance in the environment of long-term high-frequency operation. Some models are equipped with grade 12.9 high-strength screws, combined with a zinc alloy body and anodic oxidation surface treatment, endowing the product with excellent oil resistance and corrosion resistance. Even in a wide temperature range of -40°C to 100°C, it can work stably and cope with various complex working conditions with ease.

In terms of performance, this coupling can be called an "all-rounder in precision power transmission": first, its high-precision performance with zero rotational backlash perfectly meets the precise control requirements of stepper motors, ensures the synchronous operation of the system, and performs excellently in scenarios with extremely high requirements for position accuracy such as precision machining and automated production lines; second, its excellent shock absorption and noise reduction capabilities can effectively absorb vibration energy generated during equipment operation, reduce noise pollution, and are greatly beneficial to extending the service life of sensitive equipment such as optical equipment and medical instruments; third, while maintaining a compact and lightweight structure (with a weight of only 24-89g), some models can bear a torque of up to 1.2N・m, achieving a perfect balance between miniaturized design and high-strength power transmission.

In terms of installation and maintenance, the product adheres to the "convenience" design concept, supporting plug-in installation after shaft alignment, which can be quickly assembled without complex tools; daily use also does not require frequent maintenance, greatly reducing the operation and maintenance costs of the equipment. Whether it is connecting the driving components of small robots, the transmission system of 3D printers, or the precision mechanisms of semiconductor equipment, this spring coupling can significantly improve the overall operation efficiency and stability of the equipment with its comprehensive advantages of flexible compensation, high precision and high reliability, and is a high-quality choice for power connection of equipment in various fields.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.