Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

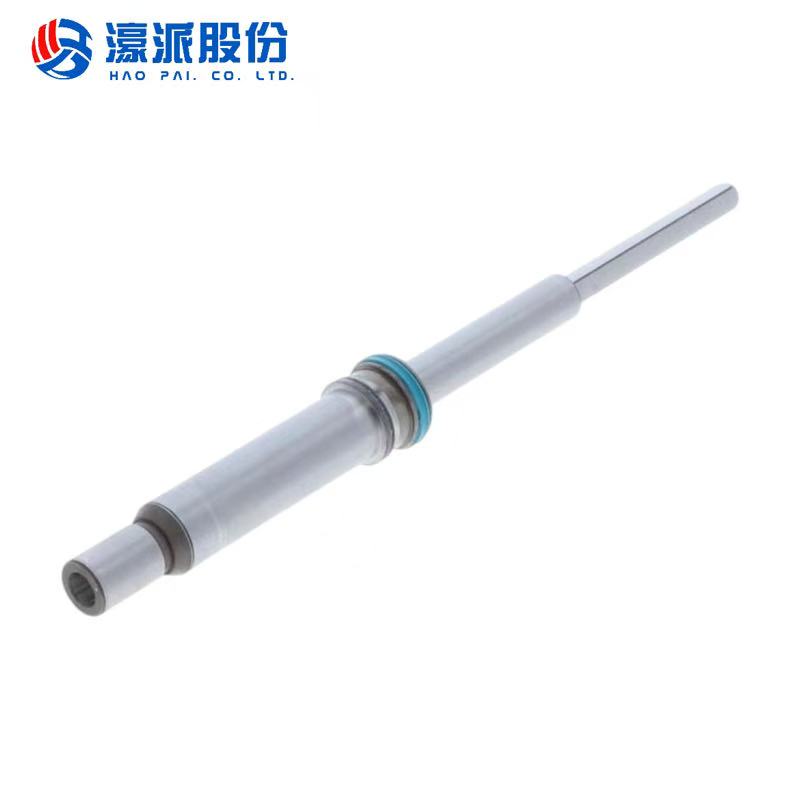

Vertical Drilling Spindle Hub60 Weeke CNC Machining Center

- Haopai

- Product origin Made in Foshan, ChinaGuangdong, China

- 5-10days

- Supply capacity 100 pcs month

- 2-031-95-4331

Product Advantages and Features

1. High-Precision Drilling Technology

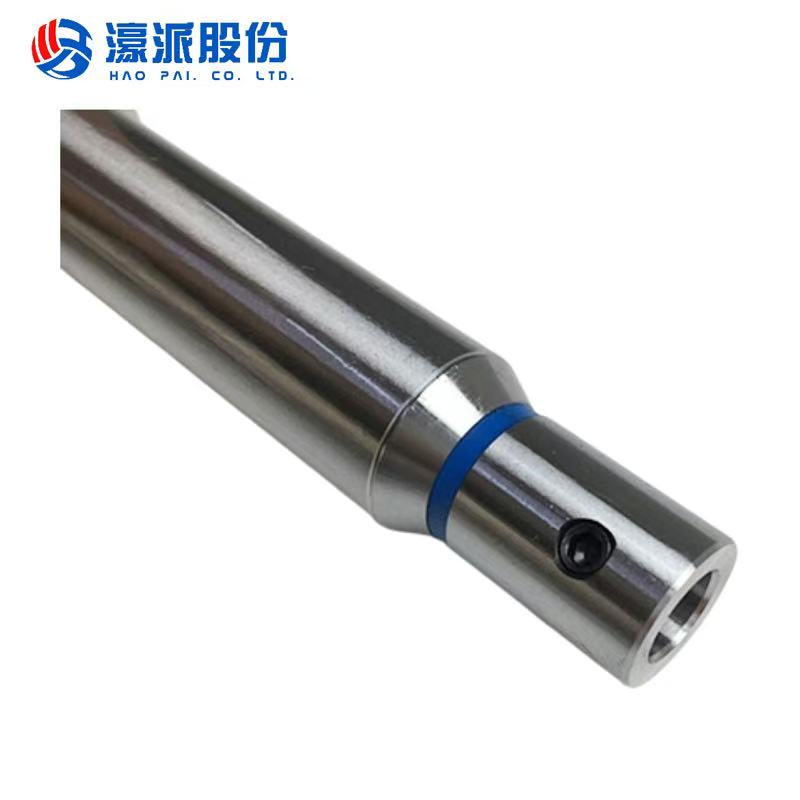

Utilizing imported ultra-precision spindle bearings with radial runout controlled within ≤0.01mm, this system guarantees exceptional positional accuracy in drilling operations.

It is ideally suited for industries with stringent hole-location requirements—including precision hardware, electronics, and furniture manufacturing.

An integrated dynamic calibration system automatically compensates for tool wear, ensuring sustained machining accuracy over extended periods.

2. High-Efficiency Multi-Axis Linkage

Featuring a V4+V5 combined architecture, the machine supports synchronous multi-axis operation (e.g., configurations with 9 or more axes), enabling single-setup completion of complex hole patterns.

This improves productivity by over 50% compared to conventional drilling systems. An optional automatic tool changer further reduces idle time and enhances adaptability to multi-process workflows.

3. Intelligent CNC System

The machine is equipped with an open-architecture CNC system (compatible with Siemens or premium domestic brands), allowing direct import of CAD/CAM files and support for complex graphic programming.

With its user-friendly touch-screen interface, built-in fault self-diagnosis, and machining parameter memory functions, operational complexity is significantly reduced.

4. Rigid and Stable Construction

Built with high-strength cast aluminum and subjected to aging treatment, the main body delivers outstanding vibration resistance and maintains structural integrity under prolonged heavy-duty operation.

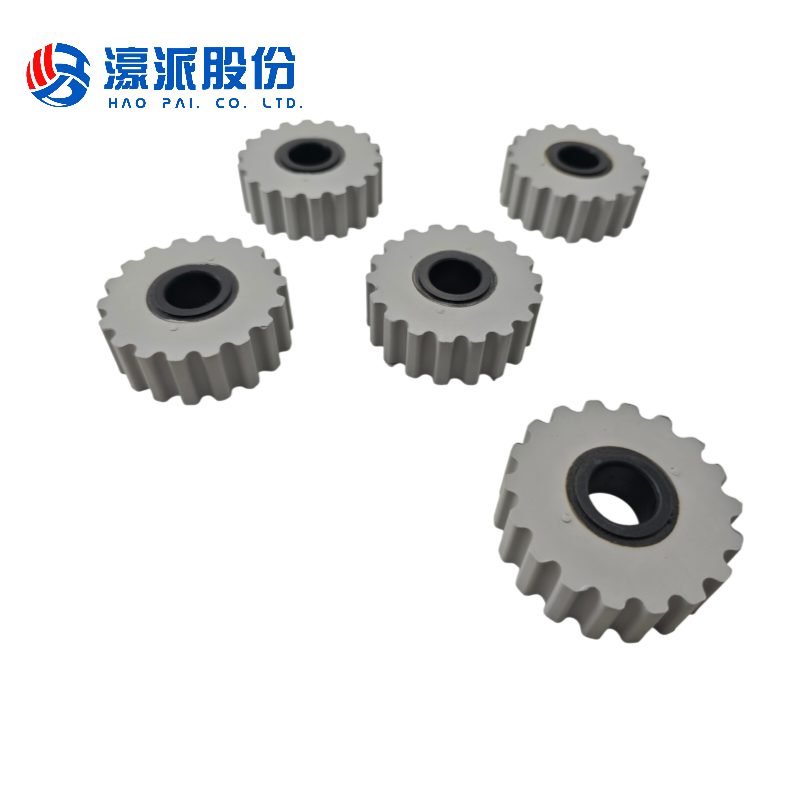

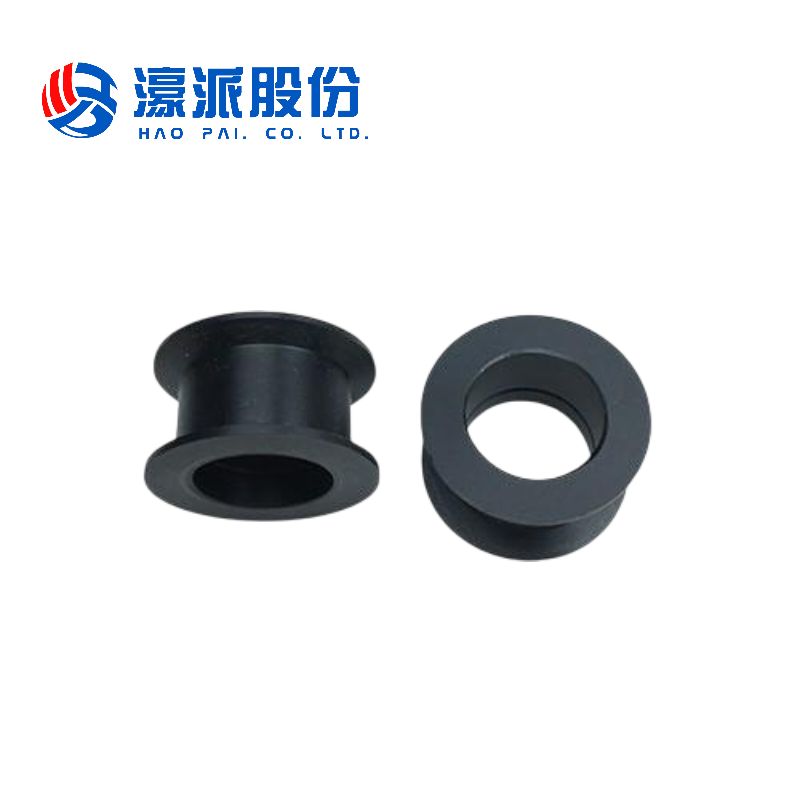

The modular drilling unit design simplifies maintenance and provides effective protection against dust and debris.

5. Flexible Adaptability

The system supports customized configurations—such as drill shaft quantity, spacing, and aperture range—to accommodate diverse materials including panels, metals, and composites.

Optional add-ons such as automatic feeding systems or robotic arm interfaces enable seamless integration into automated production lines.

Product Technical Parameters

Motor parameter | Rated power of motor | 1.7kw(S6) |

Rated voltage of motor | 380V | |

Rated power of motor | 50 Hz | |

Rated current of motor | 4.3A | |

Motor revolution | 2800 rpm | |

Unit parameter | Number of vertical drilling revolutions | 4083rpm |

Cylinder stroke | 60mm | |

Cylinder lubrication | R22 | |

Cylinder thrust | 460 N | |

Minimum air pressure requirements | 7.0bar | |

Gear lubrication | Grease 5cc every 40 hours | |

Gear lubrication | (specified grease) krub isoflex Topasl 32 n | |

Bit size | Φ10 hole depth17 | |

Bit mounting hole | Φ10 +0.009 | |

Vertical drilling run out | ≤0.03mm(manual rotation) | |

Maximum noise | 85db |

Product Application Scope

Engineered for precise vertical boring operations, our CNC drilling unit accommodates a wide spectrum of processing applications. Designed to integrate seamlessly with core woodworking machinery—including hexagonal drilling systems, cutting equipment, and PTP machining centers—it delivers comprehensive drilling solutions for panel furniture, custom cabinetry, solid wood manufacturing, and related sectors. This module empowers highly efficient, accurate, and adaptable production workflows.

Exemplary Application:

Fully-automated six-face drilling – optimized for high-efficiency operation.

Use Case: Successfully deployed in Nanxing six-sided drilling systems, specializing in vertical boring processes.

Product Description

| Advantage | Traditional drilling method | CNC drilling |

| Accuracy | ± 1mm or more, relying on worker experience | 0.1mm, CNC controlled |

| Efficiency | Single hole drilling one by one, slow speed | Synchronized processing with multiple drill bits increases efficiency by 5-10 times |

| Flexibility | Changing production requires adjusting molds, which is time-consuming | One click program switching to adapt to different products |

| Labor cost | Requires skilled workers, high training costs | Automated operations reduce the skill requirements for workers |

| Quality stability | Easy to miss or misplace drilling | The system automatically detects to ensure the pass rate |

In the fiercely competitive woodworking manufacturing industry, CNC drilling is your best choice to improve efficiency, reduce costs, and ensure quality! Choosing CNC drilling is choosing an efficient, precise, and worry free production method! Whether it's panel furniture, cabinets, wooden doors, or whole house customization, it can help you seize market opportunities and win customer trust!

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.