Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

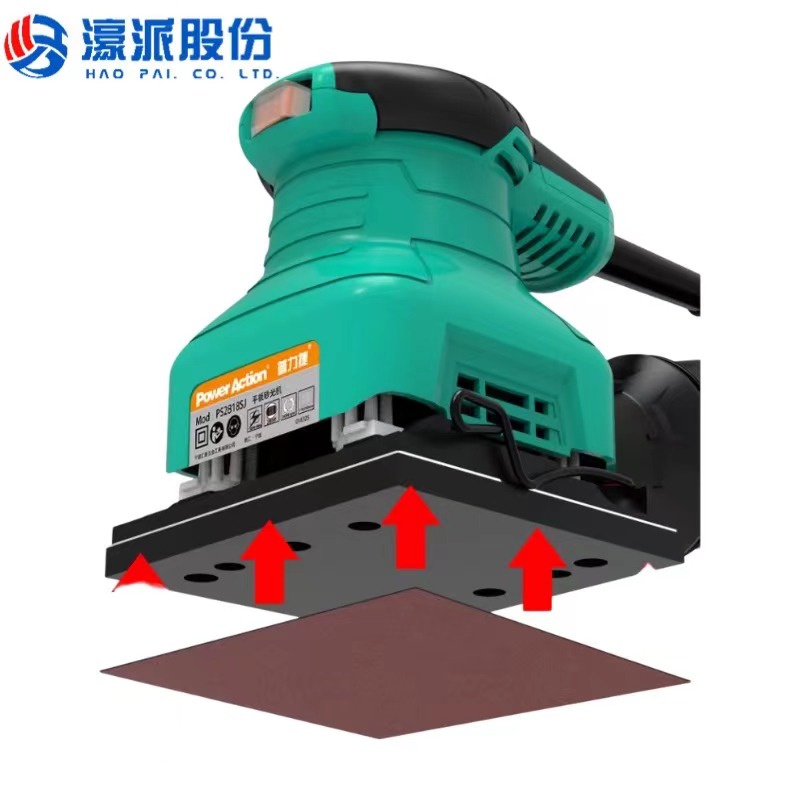

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

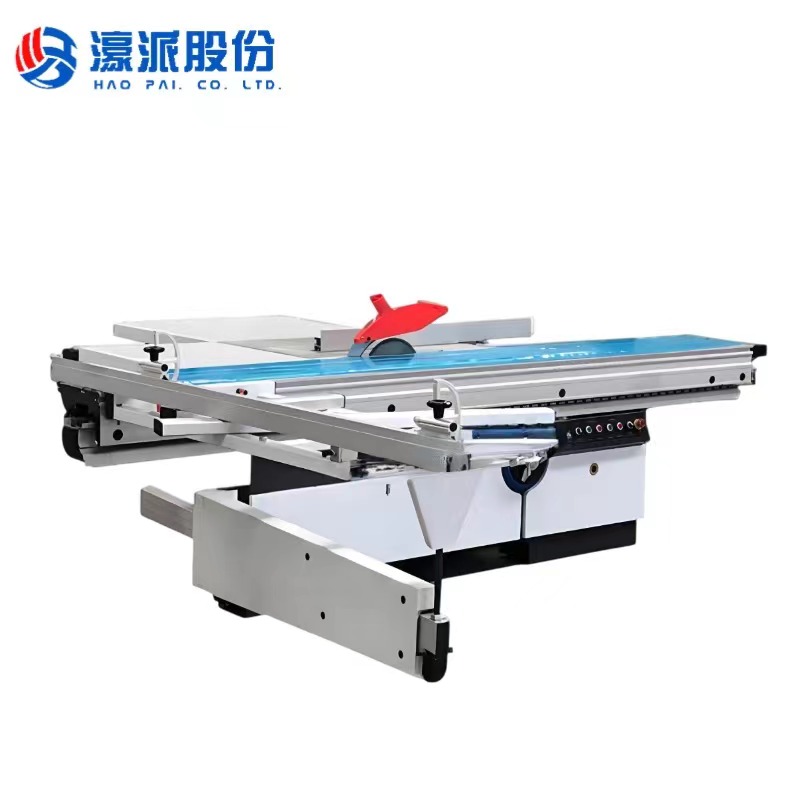

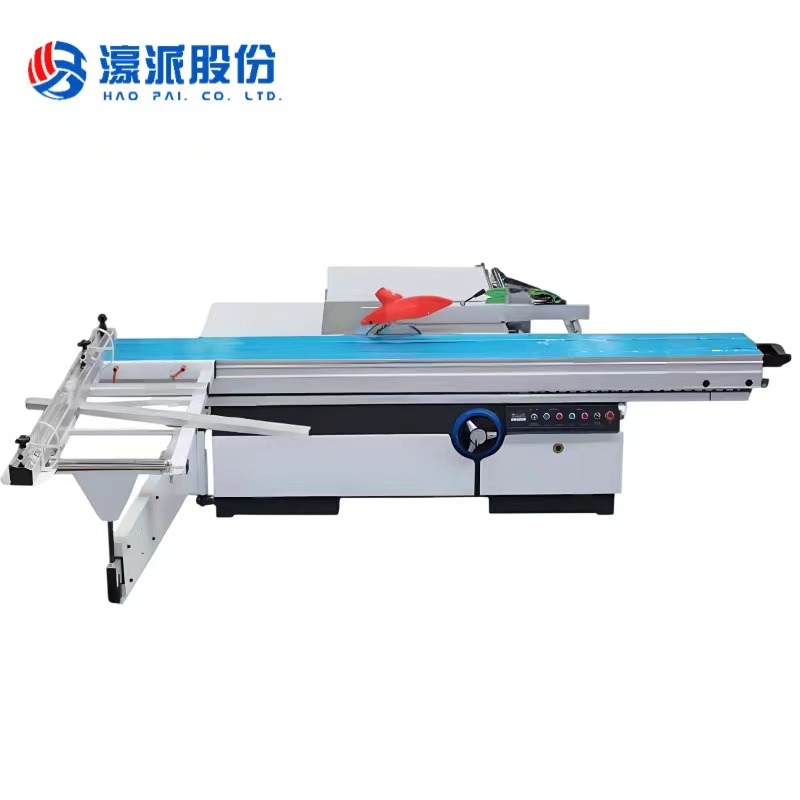

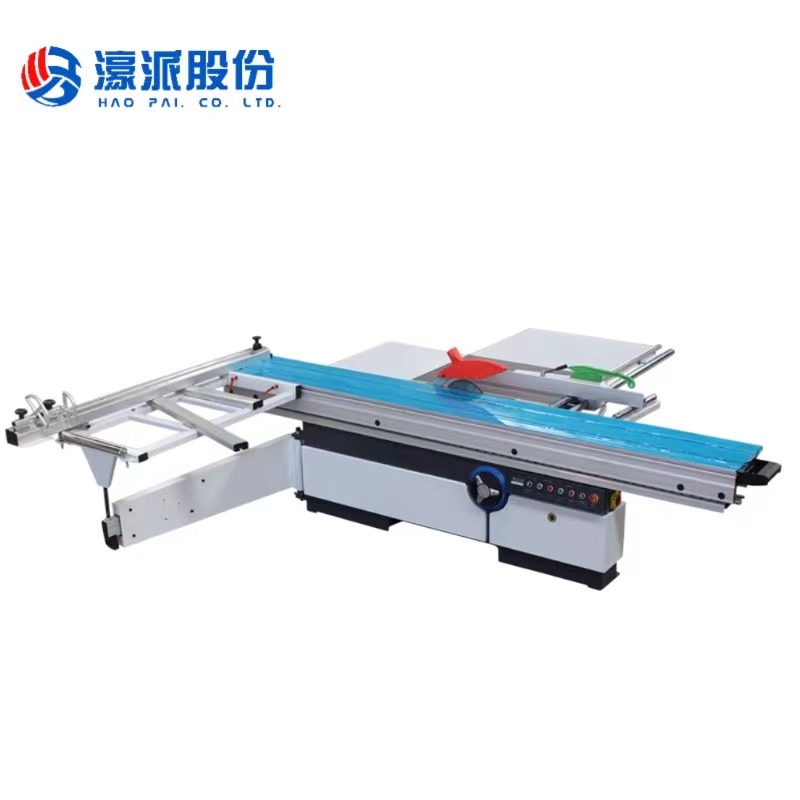

Mas 90-degree sliding table saw

- Mas

- Made in Foshan, China

- 10-15days

- 10 pcs month

- MJ6130

- 2800*1110*900mm

Product Advantages and Features

1.High-Precision Processing

· Advanced Guide Rail Structure: Adopts linear round guide rail with ball bearing structure or European-style high-seat round rod push table guide rail. Compared with traditional guide rails, it features higher precision, effectively ensuring that processed products meet high-quality and high-standard requirements. It solves the problem of guide rail degumming and maintains good precision even after long-term use.

· Precise Transmission Mechanism: The reasonably and exquisitely designed internal transmission mechanism reduces error accumulation during transmission, making movements such as push table sliding and saw blade lifting more accurate, ensuring that the dimensional precision of each sawing meets high-standard requirements.

· Aging Treatment of Components: Key components such as the machine body, fixed workbench, and movable push table undergo aging treatment to eliminate internal stress in the material, improve structural stability, and ensure that the equipment maintains high precision during long-term use.

2.Excellent Performance

· Imported Rotating Components: Uses imported rotating components, which feature low temperature rise, low noise, and low vibration. They not only extend the service life of the equipment but also create a relatively quiet and comfortable working environment for operators. Meanwhile, they help improve processing quality and reduce sawing deviations caused by vibration and other factors.

· Dual Saw Blade Design: The main saw blade and the scoring saw blade are used in conjunction. The grooving saw blade performs scoring and sawing in advance, cutting a groove with a depth of 1-2mm and a width 0.1-0.2mm thicker than the main saw blade on the bottom surface of the processed plate. This prevents the edge of the saw cut from tearing when the main saw blade is cutting, resulting in better sawing quality.

· High Power and High Rotating Speed: The main motor power is generally 4kW-5.5kW, matched with a main saw blade with a diameter of 300mm, and the spindle rotating speed can reach 4000-6000rpm. At the same time, the grooving saw blade also has high power, with a rotating speed of 7000-8000rpm. The strong power and high rotating speed make the sawing process smoother, enabling it to easily cut various materials such as density boards, particleboards, and solid wood boards, thus improving work efficiency.

3.Humanized Design

· Streamlined Push Table: The movable push table adopts a novel streamlined integral design and undergoes surface oxidation treatment. It is not only aesthetically pleasing but also made of high-strength extruded aluminum alloy, featuring high strength, no deformation, and durability.

· Easy and Labor-Saving Operation: The reasonably and exquisitely designed internal transmission mechanism makes operations such as push table sliding and saw blade lifting easier and more labor-saving, reducing the labor intensity of operators, so they are not easy to fatigue even after long hours of work.

· Clear Angle Display: The saw blade can be tilted at 0-45° and can be optionally equipped with a 0-45° digital display device. Using pulse induction, the angle tilt is very accurate. Operators can accurately know the tilt angle of the saw blade through a clear dial or digital display screen, facilitating precise adjustment according to different processing needs.

4.Multifunctionality and Expandability

· Optional Dust Collection Device: Can be equipped with a unique and novel upper dust collection device, which can automatically lift and lower as plates of different thicknesses are pushed, achieving a good dust collection effect, keeping the working environment clean, reducing dust pollution, and improving operational safety.

· Multiple Optional Accessories: Such as electric lifting for sawing, electric tilting device, right fence digital display device transmission system, etc. These can be selected according to the user's actual needs and processing requirements, further enhancing the functionality and adaptability of the equipment to meet the diverse needs of different users in different processing scenarios.

5.Wide Applicability

· Processing of Various Materials: Suitable for processing various materials with wooden structures and similar hardness, such as density boards, particleboards, artificial boards, ABS boards, PVC boards, organic glass boards, and solid wood. It has a wide range of applications and can meet the diverse processing needs of different industries and users.

Product Technical Parameters

parameter | Equipment Model | 3000×375mm |

Overall Dimensions | 2800*1110*900mm | |

Push Table Size | MJ6130 | |

Main Motor Power | 5.5KW | |

Secondary Motor Power | 1.1KW | |

Maximum Sawing Length | 2700mm | |

Maximum Sawing Width | 1250mm | |

Spindle Speed | 4500/6000rpm | |

Saw Blade Lifting | Electric Lifting | |

Sawing Angle | 90° | |

Working Voltage | 380V/220V |

Product Application Scope

Urniture Manufacturing: It can perform precise sawing and cutting of various boards such as solid wood boards, particleboards, and fiberboards. It is a common equipment in furniture factories for producing various furniture components, such as tables, chairs, wardrobes, and bookshelves. It can accurately cut out the required size and shape of the boards. Moreover, with the bevel cutting and miter cutting functions, it can produce special components like beveled tables and sloped picture frames. Meanwhile, it is also an ideal equipment for cabinet factories to cut cabinet panels, side panels and other components, helping to improve the manufacturing precision and quality of cabinets.

Wood product processing: It can be used for tenon-and-mortise processing of wood, making the tenon-and-mortise joints more tight and improving the stability of wood products. It can also cut notches on the wood surface to facilitate the embedding of tenons and mortises. In addition, when making woodworking samples and prototypes of wood products, it can display the texture, structure and shape characteristics of wood through fine cutting.

Building decoration: In the building decoration industry, it can be used to cut plywood, blockboard and other materials to meet the needs of door and window production, interior decoration modeling, etc. For example, it can cut wood for door and window frames and make decorative lines, providing wood components with precise sizes for decoration projects.

Vehicle and ship manufacturing: In the process of vehicle and ship manufacturing, some wooden interior materials or structural components need to be processed. The Maser sliding table saw MJ6130 can accurately saw the relevant boards, meeting the precision and quality requirements of wood processing in vehicle and ship manufacturing.

Other scenarios: In wood distribution stores, it can be used to cut wood according to customer needs. In addition, some small woodworking studios or individual woodworking enthusiasts can also use this equipment for various wood processing creations. With its high precision and good performance, it can help complete various woodworking projects.

![]()

Product Description

Feature Category | Specific Description |

Core Positioning | A professional woodworking equipment specially designed for high-precision plate processing, suitable for industries such as furniture manufacturing, wood product processing, and architectural decoration |

High-Precision Processing | 1. Adopts linear round guide rail with ball structure or European-style high-seat round rod push table guide rail, with much higher precision than traditional guide rails, solving the problem of guide rail degumming and maintaining stable precision during long-term use; |

Performance Advantages | 1. Equipped with imported rotating components, featuring low temperature rise, low noise, and low vibration, which extends the service life of the equipment and reduces sawing deviations; |

Humanized Design | 1. The movable push table has a streamlined overall design, with surface oxidation treatment and high-strength extruded aluminum alloy material, which is beautiful, firm, non-deformable, and durable; |

Multifunctionality and Expandability | 1. Can be equipped with an upper dust collection device that automatically lifts and lowers according to the thickness of the plate, which efficiently collects dust, keeps the environment clean, and improves safety; |

Material Applicability | Suitable for processing various materials such as density boards, particleboards, artificial boards, ABS boards, PVC boards, organic glass boards, and solid wood, meeting diverse processing needs |

The Maser 90° sliding table saw MJ6130 is a professional woodworking equipment specially designed for high-precision panel processing. With its excellent performance, user-friendly design and wide applicability, it has become an ideal choice for industries such as furniture manufacturing, wood product processing, and architectural decoration.

The equipment excels in high-precision processing: It adopts a linear round guide rail with ball bearing structure or European-style high-seat round rod sliding table guide rail, which not only has much higher precision than traditional guide rails, solves the industry pain point of guide rail degumming, but also maintains stable precision during long-term use. The internal precision transmission mechanism reduces error accumulation, making movements such as sliding table movement and saw blade lifting more accurate. Combined with the aging treatment (to eliminate internal stress of materials) of key components such as the machine body, fixed workbench and movable sliding table, it ensures that the equipment always maintains high-standard sawing dimensional accuracy.

Its performance advantages are also remarkable: Equipped with imported rotating components, it features low temperature rise, low noise and low vibration, which not only prolongs the service life of the equipment, but also creates a comfortable working environment for operators and reduces sawing deviations caused by vibration. In the double saw blade design, the scoring saw blade pre-saws a groove 1-2mm deep and 0.1-0.2mm wider than the main saw blade on the bottom surface of the panel, effectively avoiding edge tearing when the main saw blade cuts, and greatly improving the sawing quality. The main motor power reaches 4kW-5.5kW, matched with a 300mm diameter main saw blade with a rotation speed of 4000-6000rpm, and the grooving saw blade has a rotation speed of 7000-8000rpm. The strong power makes the cutting of various materials such as density boards, particleboards and solid wood boards smoother and more efficient.

User-friendly design runs through the details of the equipment: The movable sliding table adopts a streamlined overall design, undergoes surface oxidation treatment, and is made of high-strength extruded aluminum alloy, ensuring it is beautiful, firm, non-deformable and durable. The precision transmission mechanism makes the operation of sliding table movement and saw blade lifting labor-saving and convenient, reducing the labor intensity of operators. The saw blade can be tilted at 0-45°, and an optional 0-45° digital display device (pulse induction) is available, with clear and accurate angle display, facilitating precise adjustment according to processing needs.

In terms of multi-functionality and expandability, the equipment supports the installation of an upper dust collection device that can automatically lift and lower according to the thickness of the panel, which efficiently collects dust, keeps the environment clean and improves safety. It can also be equipped with optional accessories such as electric lifting for sawing, electric tilting device and right fence digital display device according to needs, further enhancing functionality and adaptability to meet diverse processing scenarios.

Its wide material applicability enables it to process various materials such as density boards, particleboards, artificial boards, ABS boards, PVC boards, organic glass boards and solid wood, covering multiple fields including furniture manufacturing, wood product processing, architectural decoration, and vehicle and ship manufacturing. Whether it is mass production in large factories or fine creation in small workshops or by woodworking enthusiasts, it can complete various woodworking processing tasks with its stable performance and high-precision performance.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.