Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

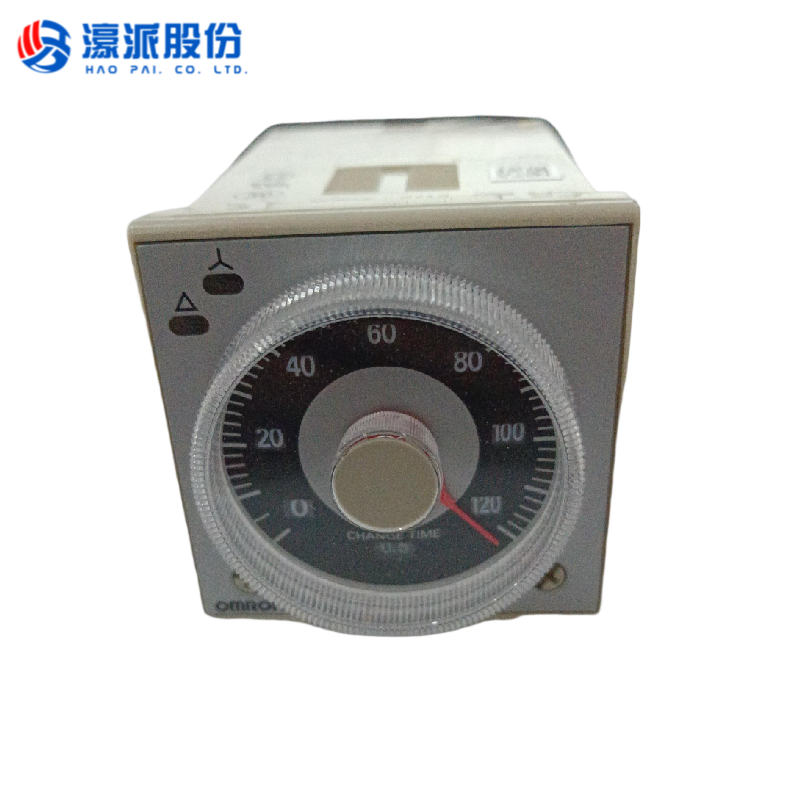

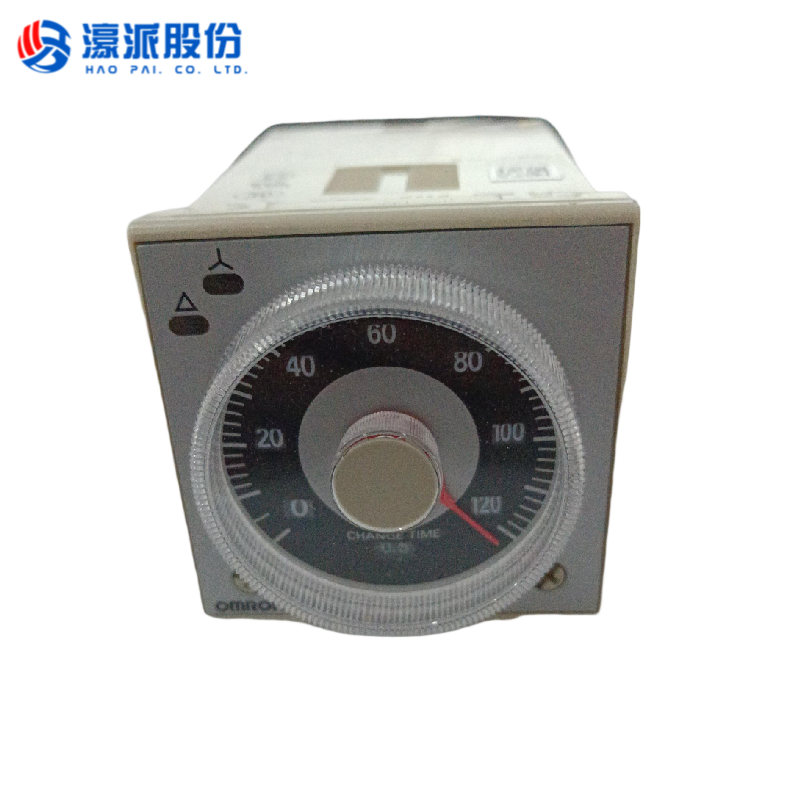

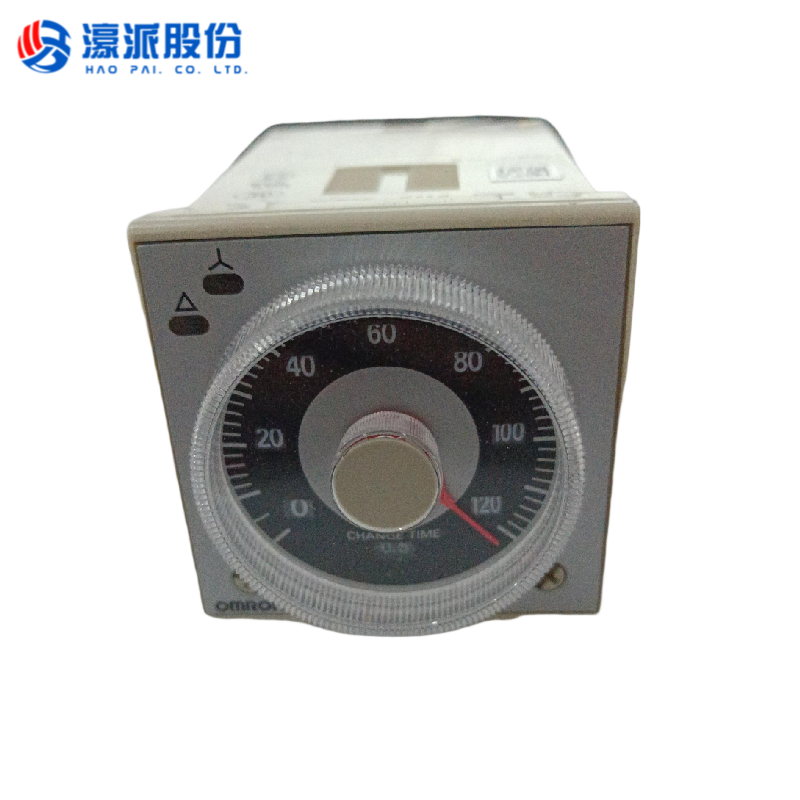

Woodworking Timers

- OMRON

- JAPAN

- 3-5DAYS

- 1000PC/MONTH

- H3BG-N8

- 84*48*4mm

Product Advantages and Features

1.Precise timing and time management

High precision: Especially hardware timers, which are usually based on crystal oscillators, can provide very high timing (microsecond or even nanosecond level), far beyond that of software loop delay.

Independent operation: Hardware timers operate independently of the CPU, not significantly by the execution speed of the main program, interrupt latency, or operating system scheduling load (within reasonable limits), ensuring the reliability and consistency of timing.

Time reference: a reliable time reference for the entire system, used to measure time intervals, calculate speed, frequency, duty cycle, etc.

2.Automation and Background Operation

CPU Liberation: Actions can be triggered automatically (e.g., interrupt, set flag bit, change level) when the timer reaches the preset value, without the need for continuous CPU polling to consume resources. The CPU can perform other tasks during the timer counting period.

Period Tasks: An ideal way to implement periodic tasks (e.g., data sampling, state scanning, LED blinking, screen refreshing). Once the timer period is, the task will automatically repeat.

Timeout Detection: Monitor whether an operation is completed within a specified time (e.g., communication wait for response, key debounce watchdog 💥).

3.Real-time response

Interrupt-driven: The timer interrupt provides the capability for real-time response to time-critical events. When timer overflow or match occurs, the CPU can immediately pause the current task to handle the event, which is crucial for real-time applications such as control systems, data acquisition, etc

4.Complex waveform generation and measurement (hardware timers)

PWM: Pulse width modulation is the core technology for driving motors, controlling LED brightness and generating analog signals, and hardware timers are key to efficiently and precisely generating PWM signals.

Input capture: Accurately measure the pulse width, period, or of external signals.

Output compare: Change the state of the output pin or trigger an event at a precise time point.

Encoder interface: Direct hardware decoding of rot encoder signals.

5.Building system foundations

The operating system clock tick: The operating system kernel relies on the system tick, a timer interrupt, for task scheduling, timeslice round-robin, and maintaining system time.

Scheduler core: Real-time operating systems or schedulers use timers to manage tasks' time constraints periodic execution.

Product Technical Parameters

woodworking Timers parameters | Precision of working hours | ±0.3%FS below |

Voltage effect | ±0.5%FS below | |

Temperature influence | ±2%FS below | |

Environmental temperature | During operation: -10°C~55°C (without icing); During storage: -25°C~65°C (without). | |

Environmental humidity | When working: 35%~85% | |

life span | Mechanical: Over 20 million times (1,800 times/hour at no load) Electrical: Over 100,00 times (AC250V 5A resistive load, 1,800 times/hour) | |

Shell color | Light gray | |

protection level | IEC: IP40 (panel surface) | |

Weight | About 110g |

Product Application Scope

The core advantage of the timer lies in providing high-precision, automated, non-blocking, and CPU-saving time management and event triggering capabilities, are the cornerstone of achieving real-time, periodic tasks, complex waveform control, and efficient systems. Its features are reflected in the differences in hardware/software implementation, diverse triggering, rich configurable options (clock, division, mode), and the powerful multi-functional integration of hardware timers (PWM, capture/compare, etc.)

Product Description

Advantage | woodworking Timers | Different input sources |

Precision and stability | The hardware timer is based on a crystal oscillator and can time up to microsecond/nanosecond level. | Depending on the CPU instruction cycle, it is susceptible to interrupt blocking or interference from system load, and the error significantly increases. |

CPU resource usage | The timer operates independently of the CPU, with the counting process taking zero CPU time. | Continuous consumption of computing resources, resulting in system response latency |

Functional extensibility | Support PWM waveform generation, input capture (measure pulse width), encoder interface, and other hardware-level functions. | Only basic delay can be achieved |

In scenarios requiring high-precision time reference, low latency response, and multi-channel coordination, such as industrial automation, hardware timers are the only reliable solution.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. It is currently a one-stop procurement platform with a complete range of categories in the industry.We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories.We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.