Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

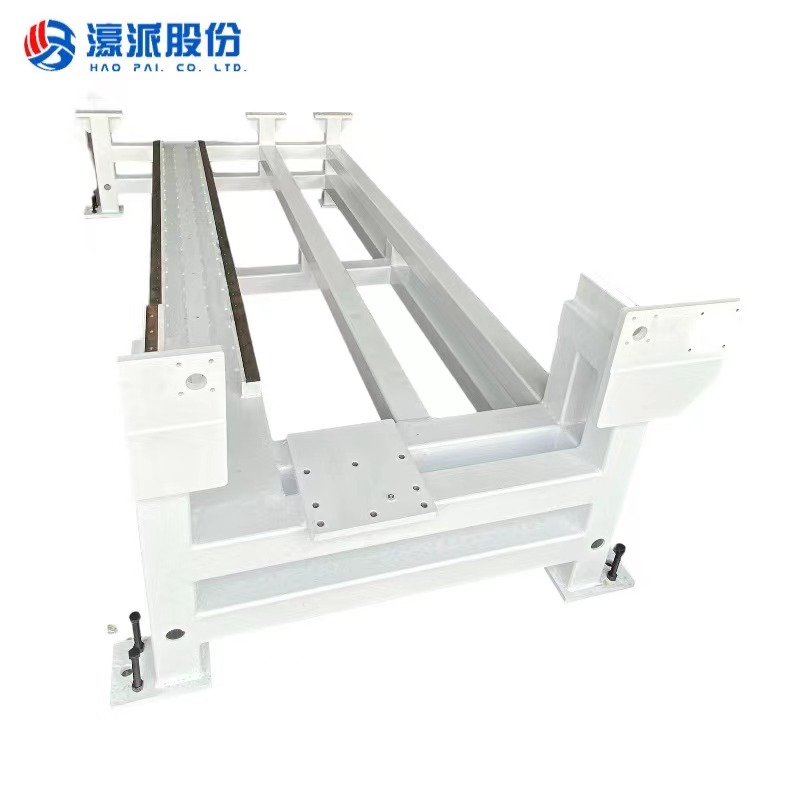

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

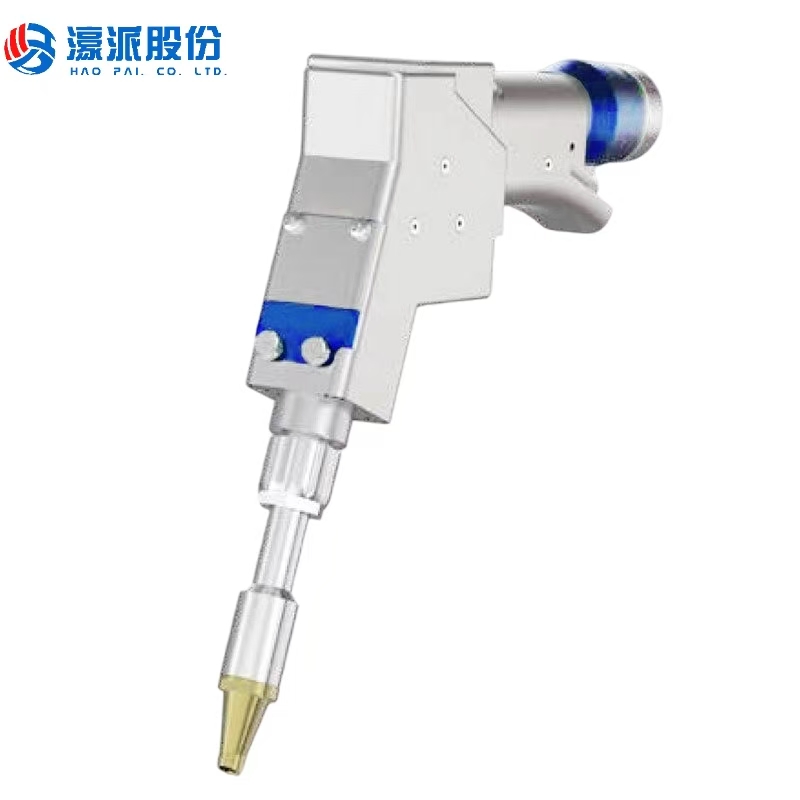

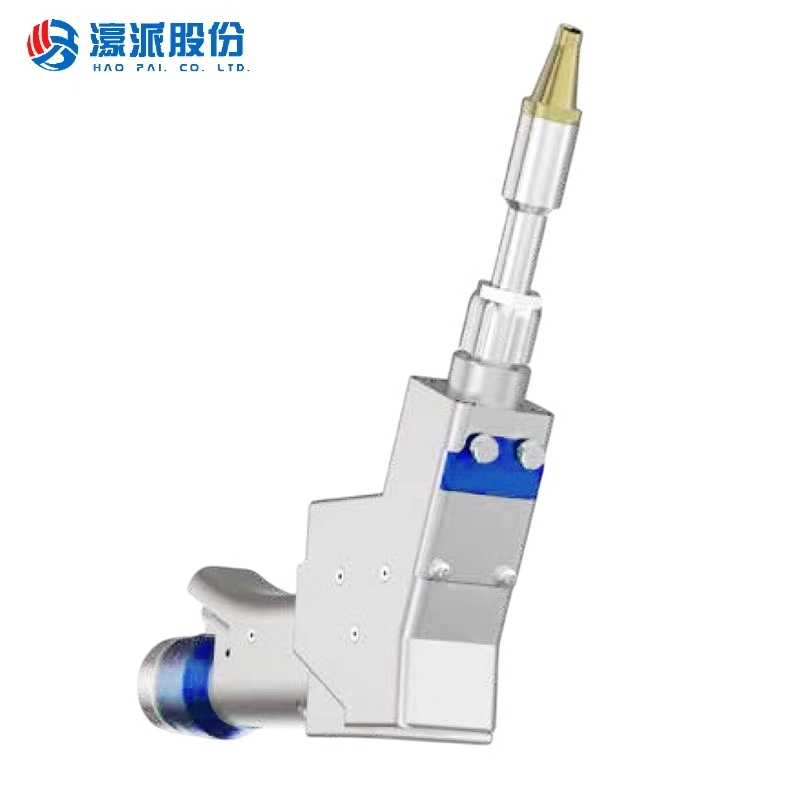

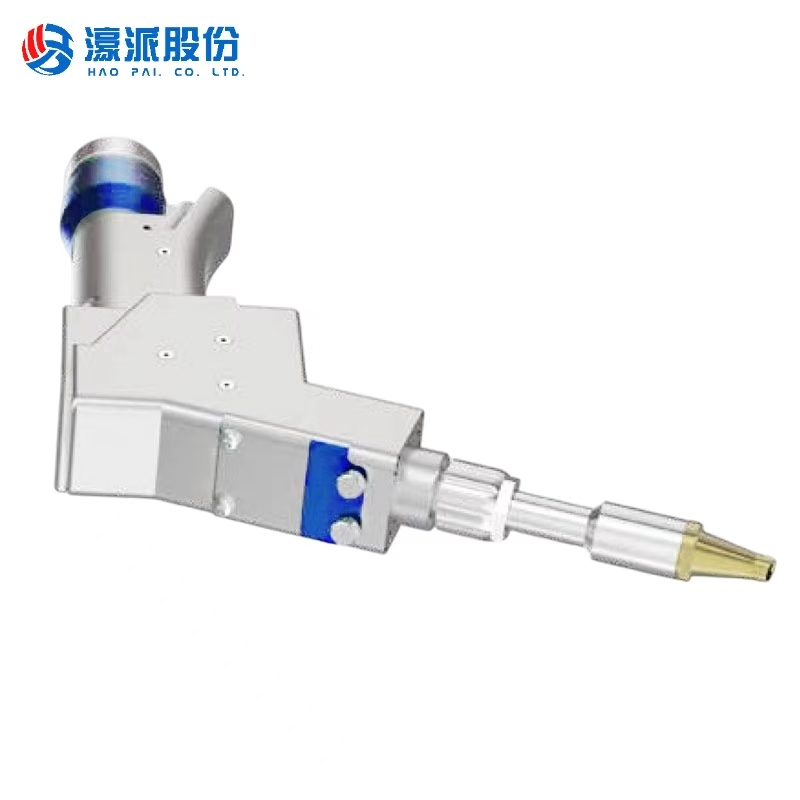

2kw 1070nm Wavelength Single Galvo Handheld Welding Head

- Haopai

- China

- 5-10days

- 100000

- BW101-GD

Product Advantages and Features

1. More Stable Welding Quality with Significantly Reduced Defect Rates The "controllable dual-axis oscillation" of the dual-galvo head is a core technical highlight, which fundamentally optimizes the molten pool shape and weld formation: - Improved Uniformity of Weld Penetration: During oscillation, laser energy can evenly cover a larger area, avoiding issues like "incomplete fusion" and "uneven penetration" caused by traditional single-point heating, especially suitable for multi-pass welding of thick plates. - Better Weld Formation: It supports various controllable oscillation trajectories such as sine waves and sawtooth waves, which can promote the full flow of molten pool metal, significantly reducing common welding defects like "undercut", "porosity" and "cracks". The tensile strength and sealing performance of the finished welds are greatly improved. - Smaller Heat-Affected Zone (HAZ): The laser energy guided by the galvo has higher focusing accuracy. Combined with the oscillation design to disperse local heat, it can effectively reduce the probability of high-temperature deformation of easily deformable materials such as stainless steel and aluminum alloys. 2. Lowered Operation Threshold, Enabling Novices to Master Quickly The combination of handheld design and intelligent galvo guidance greatly simplifies the operation process and reduces reliance on welders' skills: - No Need for Precise "Torch Tracking": Traditional handheld welding requires welders to manually control the distance and angle between the torch and the weld seam, and even slight deviations will affect the quality. The dual-galvo head automatically corrects the welding trajectory through the galvo, and the welder only needs to roughly align with the weld direction, and the device can automatically complete the oscillating welding. - Visual Parameter Adjustment: Most devices support setting parameters such as oscillation amplitude (adjustable from 0.1 to 5mm), oscillation frequency, and welding speed through the control panel or APP, without relying on the welder's "experience judgment". Parameters can be saved and reused to ensure the consistency of batch operations. - Lightweight Design: Compared with traditional heavy welding torches, the handheld unit of the dual-galvo head weighs mostly 1-3kg, which is not easy to cause fatigue during long-term operation and reduces the physical consumption of welders. 3. Wide Application Range, Compatible with Complex Working Conditions It can not only meet conventional welding needs but also solve complex welding problems that are difficult for traditional equipment to handle: - Strong Material Compatibility: It can be adapted to various metals such as stainless steel, carbon steel, aluminum alloys, titanium alloys, and copper alloys. Especially for highly reflective materials like aluminum alloys, the dynamic focusing function of the galvo can offset the energy loss caused by reflection and ensure the welding effect. - Full Coverage of Weld Types: It can stably complete common weld types such as butt welds, lap welds, and fillet welds. At the same time, it can compensate for the assembly gap of 1-3mm by adjusting the oscillation amplitude, adapting to "small gap" and "large gap" welding, and can also easily handle the welding of curved surfaces and special-shaped parts (such as pipes and cavity parts). - Good Adaptability to Narrow Spaces: The handheld unit is small in size and can go deep into narrow areas that traditional equipment cannot reach (such as internal welds of equipment and gaps between dense parts). Welding can be completed without disassembling the workpiece, improving production efficiency. 4. Higher Welding Efficiency, Significant Advantages in Batch Operations Combined with intelligent control and rapid response technology, the welding volume per unit time is 30%-50% higher than that of traditional handheld welding: - Adjustable Oscillation Speed: The maximum oscillation frequency can reach 500Hz, which is much higher than the manual oscillation speed, and there is no need to start and stop the equipment frequently, reducing the consumption of invalid time. - No "Torch Replacement" Waiting: Traditional welding may require replacing nozzles and welding wires for different welds, while the dual-galvo head only needs to adjust parameters to switch working conditions, greatly shortening the auxiliary operation time. - Support for Automated Linkage: Some models can be linked with robotic arms and welding workbenches to realize the switching between "handheld" and "semi-automatic" modes, further improving efficiency in mass production (such as welding of new energy battery cases and hardware parts). 5. Lower Post-Maintenance Costs, Longer Equipment Service Life Both structural design and consumable selection focus on "durability" and "maintainability": - Long Service Life of Core Components: Core components such as galvo motors and laser focusing lenses are made of high-wear-resistant and high-temperature-resistant materials, with a service life of 8000-10000 hours under normal use, far exceeding the service life of core components of traditional welding torches. - Easy Consumable Replacement: Vulnerable consumables such as protective lenses adopt a snap-on design, which can be quickly replaced without professional tools, reducing the equipment downtime for maintenance. - Low Failure Rate: The integrated circuit design reduces the number of wire connection points, lowering the failure probability caused by loose wires, and ensuring stronger stability during long-term use.

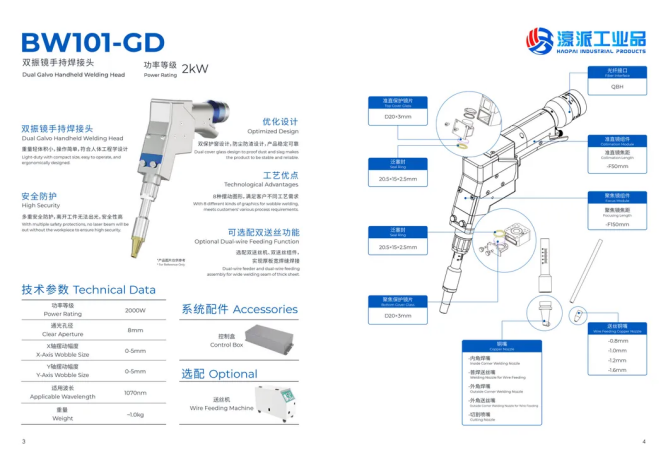

Product Technical Parameters

Product Application Scope

Light-duty with compact size, easy to operate, and ergonomically designed

With multiple safety potections, no lase beam will be out without the workpiece to ensue high secuity.

Dual cove glass design to proof dust and slag makes the poduct to be stable and reliable

Suitable for various welding techniques, like continuous welding and spot welding

Vaious tip assemblies in standad kit to fulfill needs of cutting, welding, welding seam cleaning and emote cleaning

Dual-wire feeder and dual-wie feeding assembly for wide welding seam of thick sheet

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.