Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

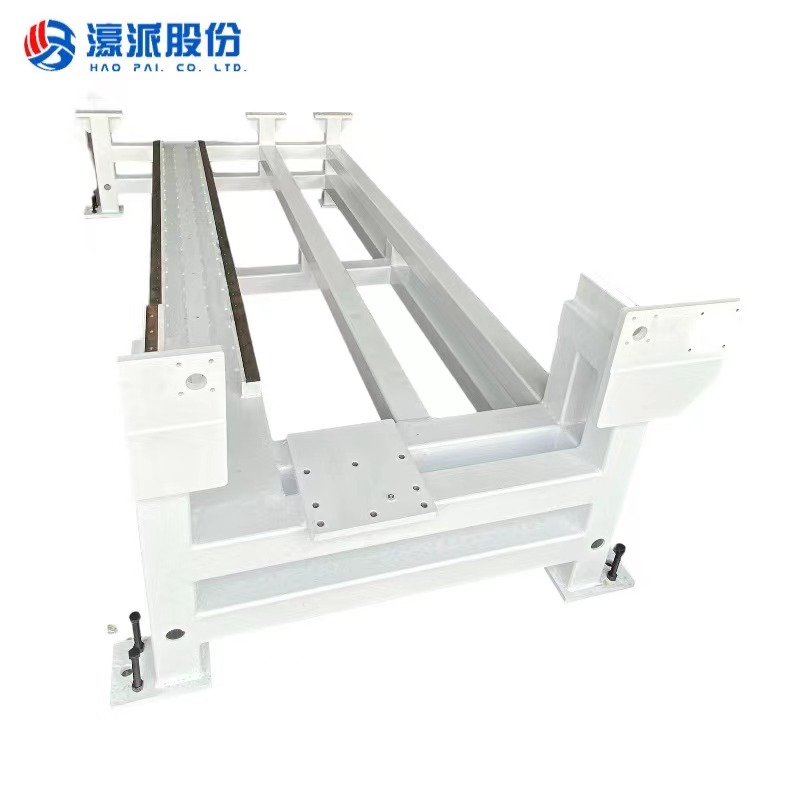

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

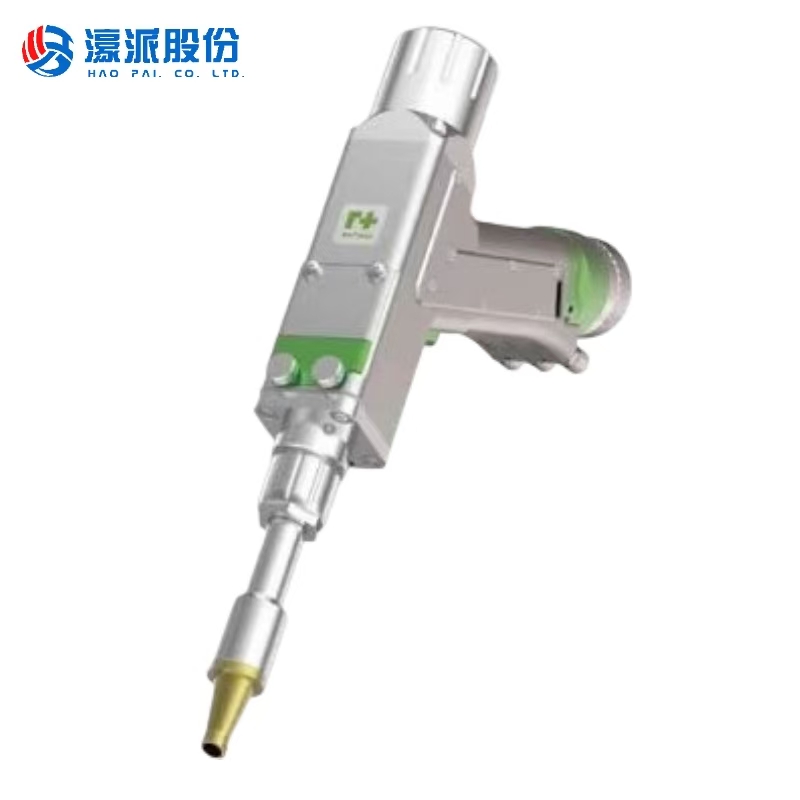

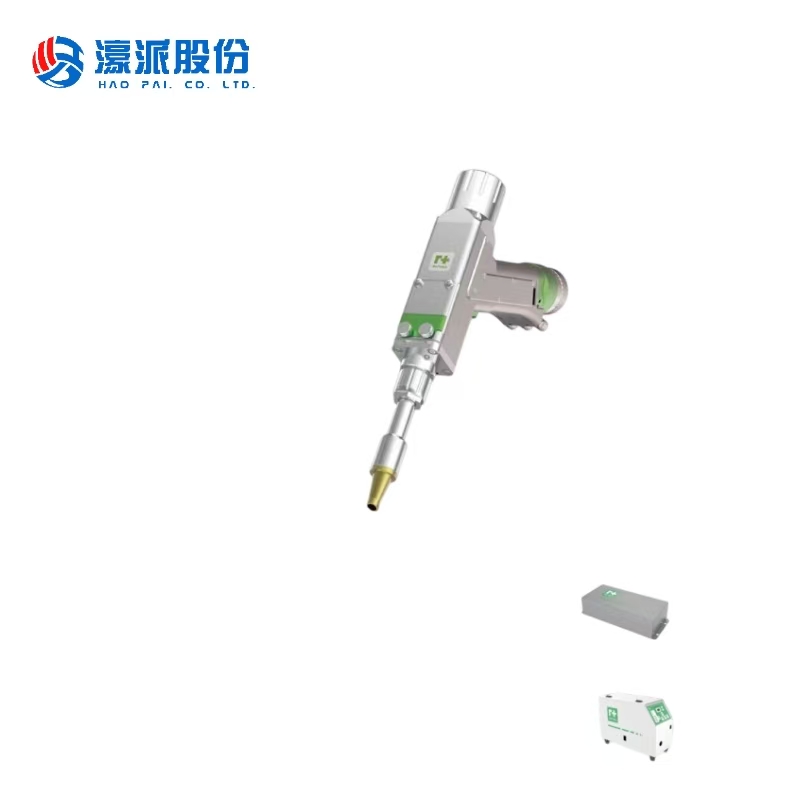

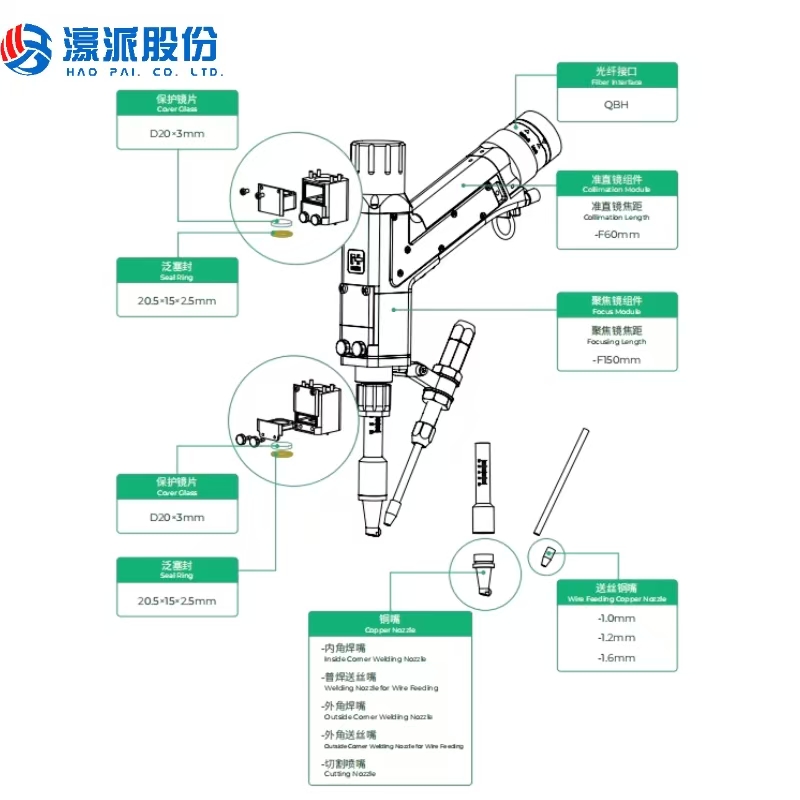

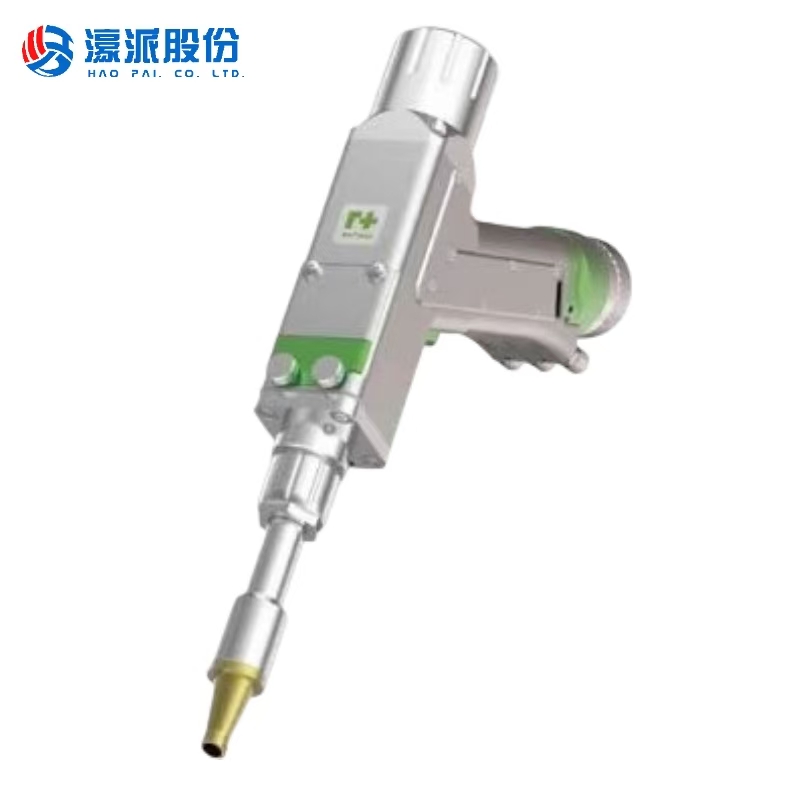

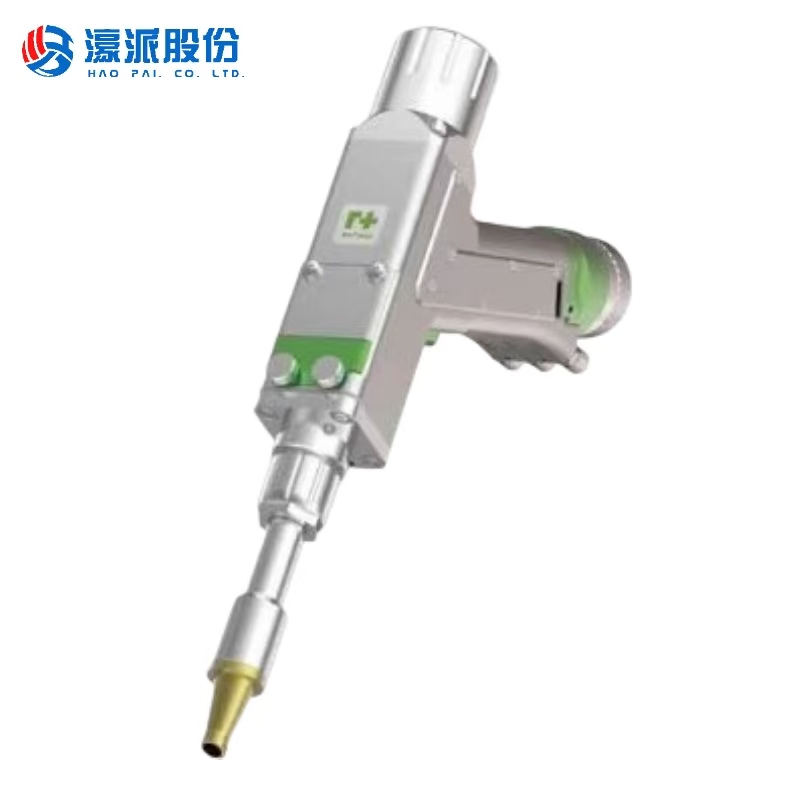

2kw/3kw Single Galvo Handheld Welding Head

- Haopai

- China

- 5-10days

- 100000

- RT BW101-GS

Product Advantages and Features

By welding to firmly connect wood beams with high-strength metal components (such as angle steels and connecting plates), it can effectively transfer loads, avoid loosening issues that may occur with traditional bolted connections, and make wood beams more stable in load-bearing scenarios (such as wooden house roofs and large wooden frame platforms), enabling them to bear greater weight and external impact.

:The connection joints of wood beams are weak links in the structure. The welding process allows the wood beams and metal parts at the joints to form an integral stress-bearing structure, reducing joint deformation caused by temperature changes, humidity fluctuations, or long-term use, and extending the overall service life of the wood structure. Compared with connection methods such as bolts and mortise-tenon joints, welding is more flexible. It can adjust the welding position and angle of metal connectors according to the complex shape of the wood structure design (such as special-shaped wood beams and irregular support frames), meeting the personalized and diversified design needs of woodworking structures, especially suitable for customized wood structures or large woodworking products. For some large-scale wood structure projects, prefabricating the welding of wood beams and metal parts in the factory in advance, and only needing to perform overall splicing on-site, can reduce cumbersome on-site processes such as drilling and bolt tightening, and shorten the construction period; at the same time, welding operations do not require complex mortise-tenon processing techniques, reducing reliance on the high-precision manual skills of woodworkers. Welding can hide most of the welding points of metal connectors inside or on the side of the wood beam structure, avoiding the situation where a large number of exposed fasteners in traditional bolted connections affect the natural aesthetics of the wood structure, making woodworking finished products (such as wooden display stands and indoor wood structure decorations) more concise and coordinated, in line with modern aesthetic needs.

Product Technical Parameters

| Model NO. | BW101-GS | Transport Package | Package |

| Origin | Guangdong, China | Trademark | Haopai |

| Type | Sensor Welding Machine | Laser Classification | Optical Fiber Laser |

| Specification | piece |

Product Application Scope

Accurate vertical drilling, suitable for multi scene processing needs

Our CNC drilling kit is designed for high-precision vertical drilling and can be perfectly integrated into core woodworking equipment such as hexagonal drills, cutting machines, PTP machining centers, etc. It fully covers the drilling needs of panel furniture, customized home furnishings, solid wood processing, and other fields, helping you achieve efficient, precise, and flexible production.

Six sided drilling integration - efficient fully automatic drilling.

Equipment case: Applied to Nanxing six sided drill, mainly processing vertical holes

Product Description

Light-duty with compact size, easy to operate, and ergonomically designed

With multiple safety potections, no lase beam will be out without the workpiece to ensue high secuity.

Dual cove glass design to proof dust and slag makes the poduct to be stable and eliable

Suitable for various welding techniques, like continuous welding and spot welding

Vaious tip assemblies in standad kit to fulfill needs of cutting, welding, welding seam cleaning and emote cleaning

Dual-wire feeder and dual-wie feeding assembly for wide welding seam of thick sheet

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.