Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

Air Gas Shock Spring Cylinder Absorber Type 1600n for Homag

- Haopai

- China

- 5-10days

- 100 a month

- 4010040092

- 1600N

Product Advantages and Features

1. Height Adjustability

The shock absorber's height can be modified by regulating the gas volume, enabling adaptation to diverse road surfaces and user needs.

For instance, the vehicle can be lifted to enhance off-road capability on uneven terrain, or lowered to boost stability on paved roads.

2. Enhanced Riding Comfort

By using an air bag in place of conventional springs, the system responds with high sensitivity and effectively absorbs minor road vibrations,

delivering a smooth and comfortable driving feel that elevates the journey to a cloud-like experience.

3. Excellent Impact Resistance

Thanks to precise air pressure management, the air bag operates within a predetermined maximum pressure threshold. Upon impact,

it compresses rapidly to shield the vehicle body from harm and prevent damage to key components such as tires, wheels, and the suspension caused by over-compression.

4. Space-Saving Design

Featuring a simplified internal structure and compact form, it allows for straightforward installation and maintenance.

The reduced size helps conserve assembly space, while also streamlining servicing procedures.

5. High Adaptability

It dynamically adjusts the working pressure of nitrogen (or other gases) based on current road conditions or load variations,

thereby altering the shock absorber’s firmness to suit changing environments. Whether on smooth expressways or rugged mountain paths, it consistently ensures effective damping performance.

Product Technical Parameters

1 | Size | 16 |

2 | Stroke | 20mm |

3 | Cushioning | Adjustable |

4 | Max. Impact Velocity | 3m/s |

5 | Reset Time at Min. Ambient Temperature | 1s |

6 | Mode of Operation | Single - acting Pushing |

7 | Corrosion Resistance Class | 1 - Low Corrosion Stress |

8 | Labs (PWIS) Conformity | VDMA 24364 - B2 - L |

Product Application Scope

1、Applicable equipment types

It is suitable for the relevant mechanical equipment of KAL, KFL and Ambition series produced by Homag Group. These equipment are usually used in the wood - processing and other fields. The 1600n pneumatic shock absorber can help reduce vibration during operation, and improve processing accuracy and equipment stability.

2、Applicable working - condition environment

It can work in an ambient temperature range of - 10 °C to 80 °C, and can adapt to a certain range of temperature changes. It has a certain adaptability whether in a relatively cold workshop environment or in a high - temperature environment where heat is generated due to equipment operation.

Product Description

1. Product Positioning and Compatibility

This product is engineered specifically for Homag Group's KAL, KFL, and Ambition series machinery.

It serves as a dedicated component for vibration damping and impact protection in these systems and is not designed as a universal shock absorber.

Precise matching with the model-specific mounting interfaces and load specifications is essential for proper operation.

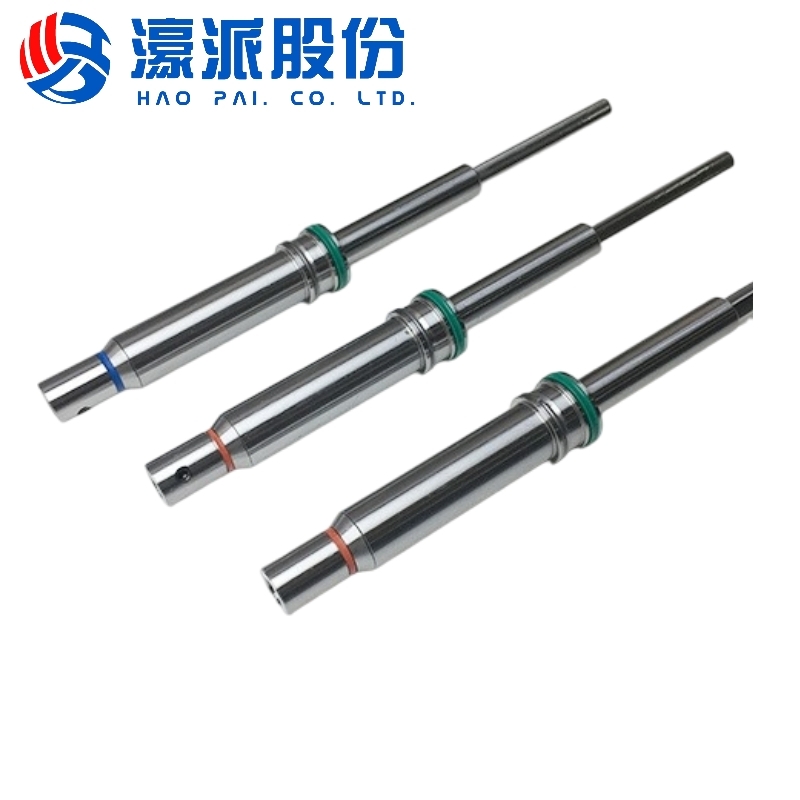

2. Core Operating Mechanism

Compressed gas—typically nitrogen—functions as the damping medium. Energy is absorbed via the compression and rebound of an internal air capsule.

Upon impact or vibration, the gas compresses to dissipate kinetic energy, then uses pre-set pressure to return components to their original position.

This process occurs without dependence on traditional metal spring mechanisms.

3. Key Performance Metrics

The unit offers a maximum damping force of 1600N, energy absorption per stroke of up to 32J, and hourly energy handling capacity of 100,000J.

These properties allow it to effectively sustain damping under medium-impact, high-frequency operating conditions, thereby reducing component wear and maintaining equipment accuracy over prolonged use.

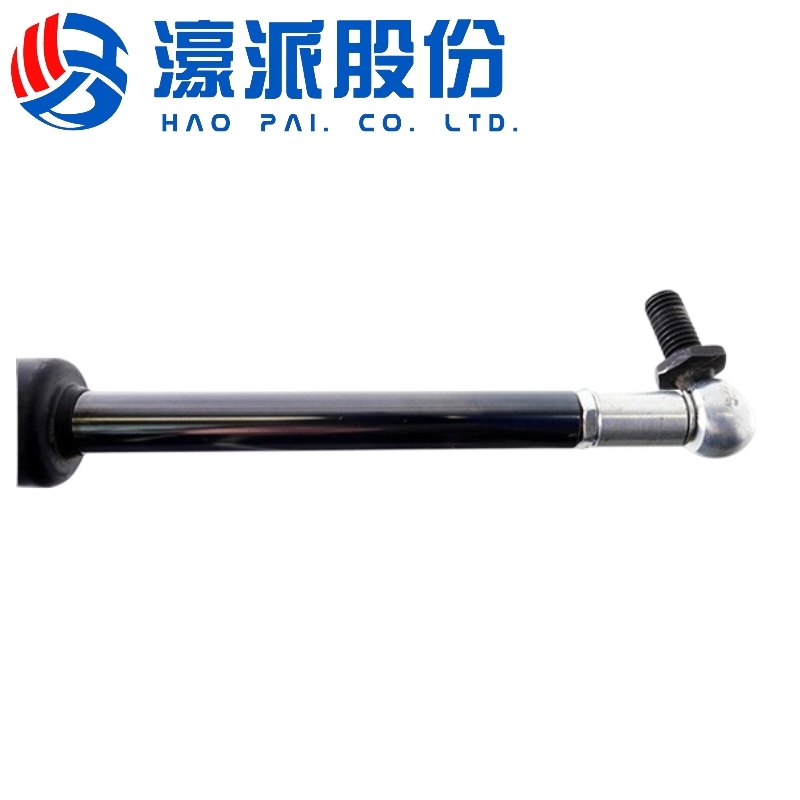

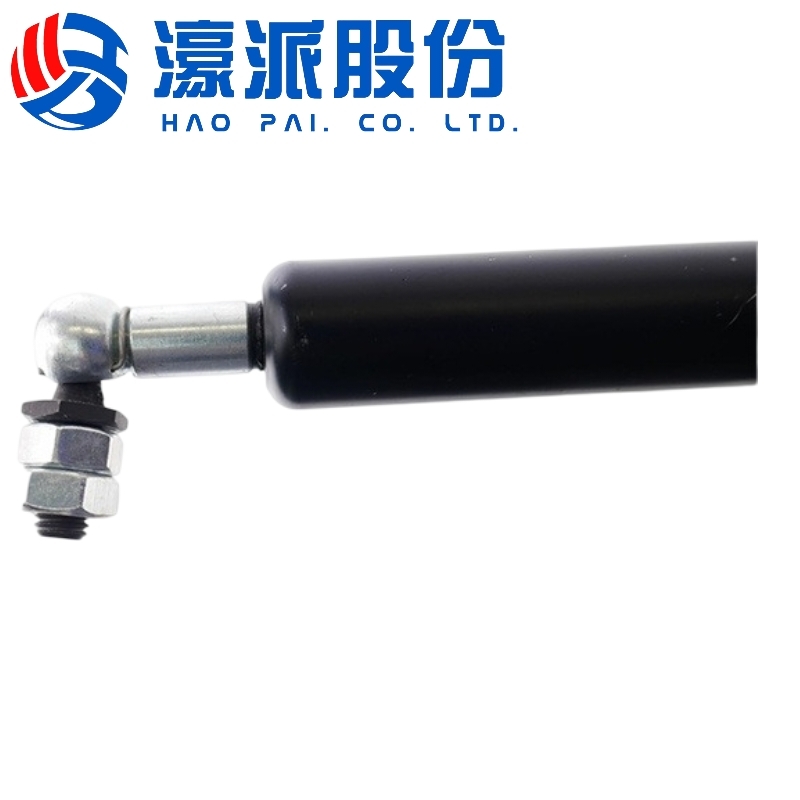

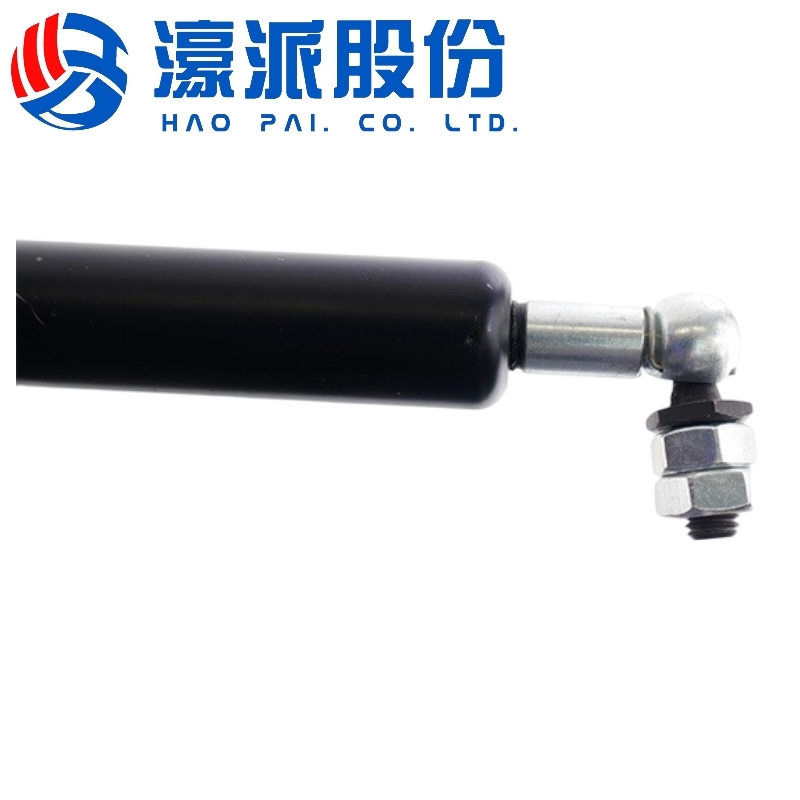

4. Construction and Material Specifications

The housing is constructed from zinc-plated steel, complemented by a hardened high-alloy piston rod and nitrile rubber (NBR) seals.

The housing provides basic corrosion resistance (Corrosion Resistance Class 1 – low corrosive stress). The sealing mechanism minimizes gas leakage to ensure consistent air pressure throughout extended service.

With a total weight of 200g, the unit employs a nut-mounting design for compatibility with predefined equipment installation points.

5. Operational and Environmental Guidelines

Suitable for operating temperatures from -10°C to 80°C and low-corrosion environments only. The product conforms to VDMA 24364 - B2 - L standards and RoHS environmental requirements.

Use outside the specified temperature range, in highly corrosive conditions (e.g., acidic or alkaline settings), or under overload is strictly prohibited to maintain damping performance and prevent part failure.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.