Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

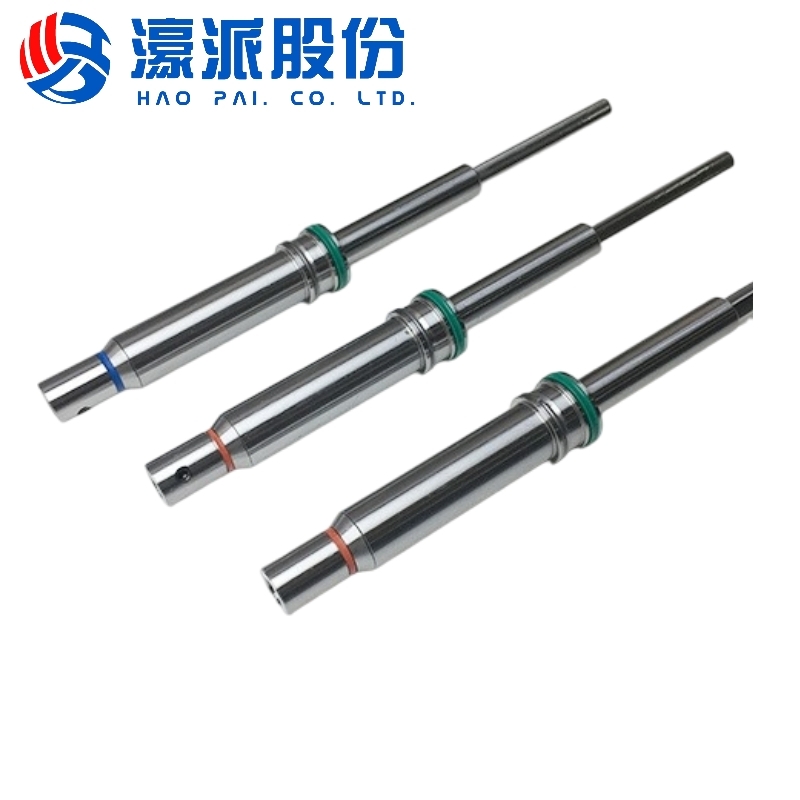

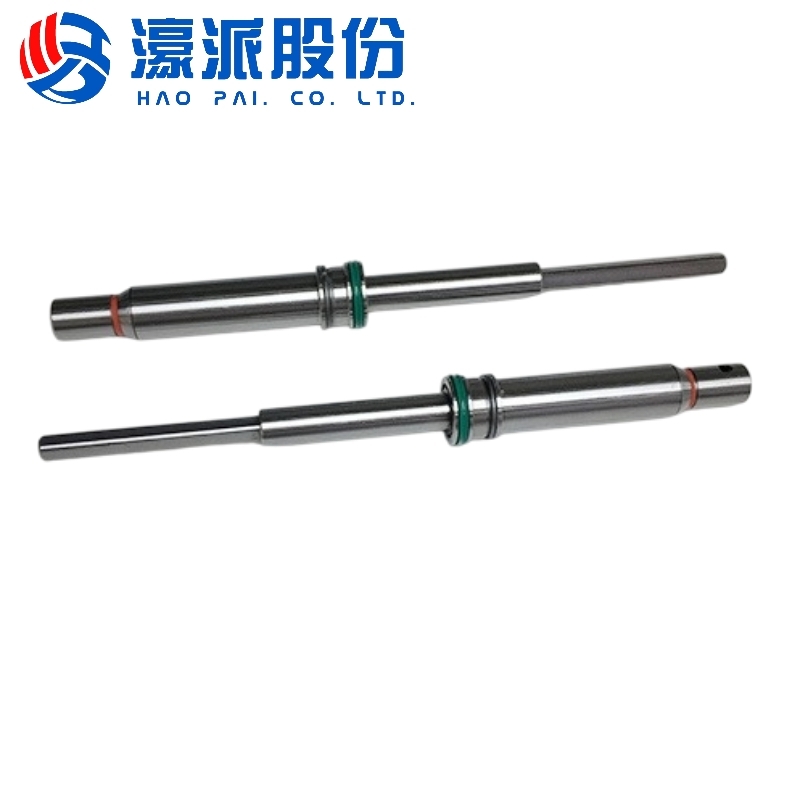

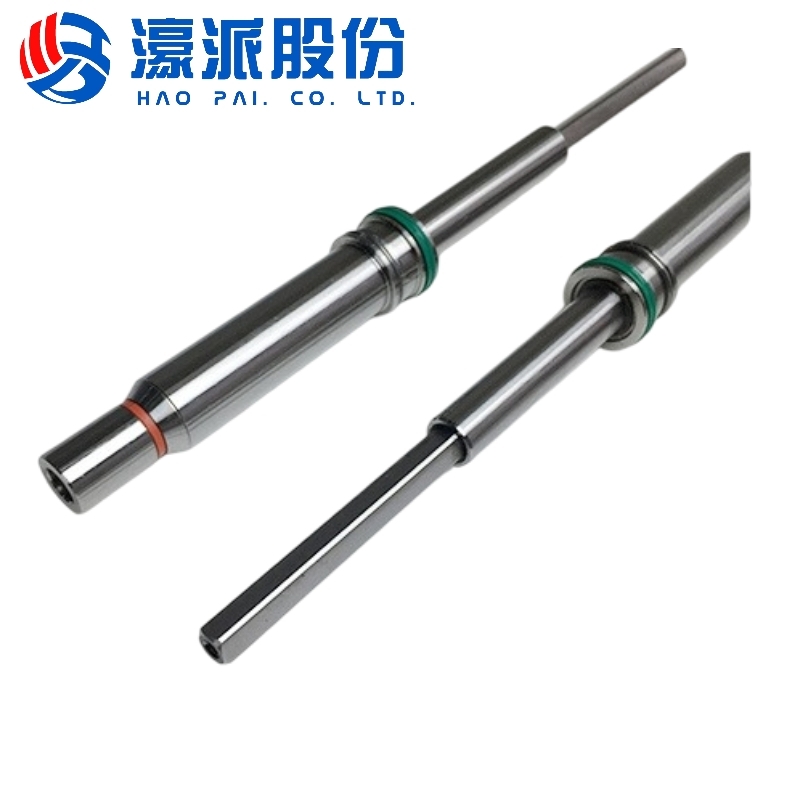

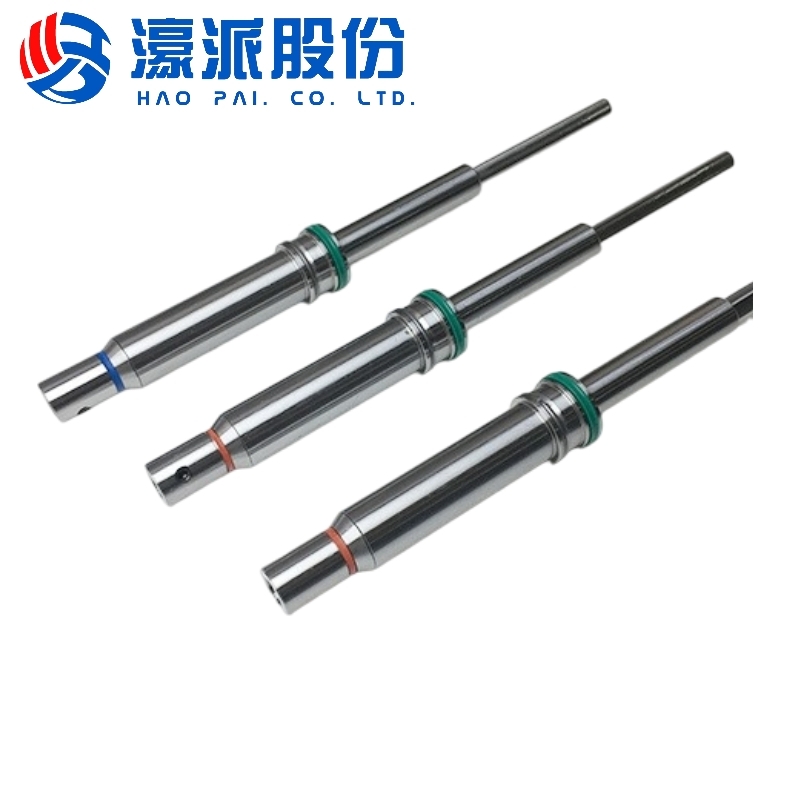

Boring Spindle Boring Shaft for Homag Woodworking Machine

- Haopai

- China

- 5-10days

- 100 a month

- 2031954491 2031954331

Product Advantages and Features

1、 Standardized structure design, compatible with universal installation;

Adopts industry-uni

versal shaft diameter tolerances (e.g., h6, h7) and mounting interface types (key connection, thread connection), which can match with bearing housings and transmission components of most equipment without additional customization, reducing assembly difficulty.

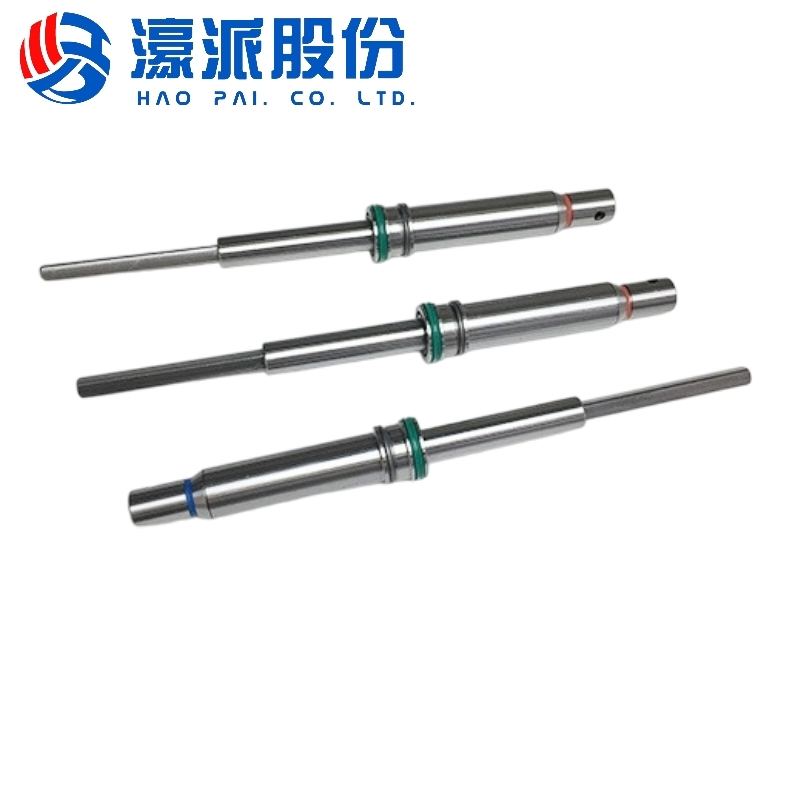

2、 Material classification is clear, corresponding to different working conditions

According to the differences in application scenarios, the material types are clearly divided: ordinary carbon steel is suitable for dry and low-load environments; alloy steel is suitable for medium and high-load scenarios; stainless steel is for humid and corrosive environments, facilitating users to select models on demand.

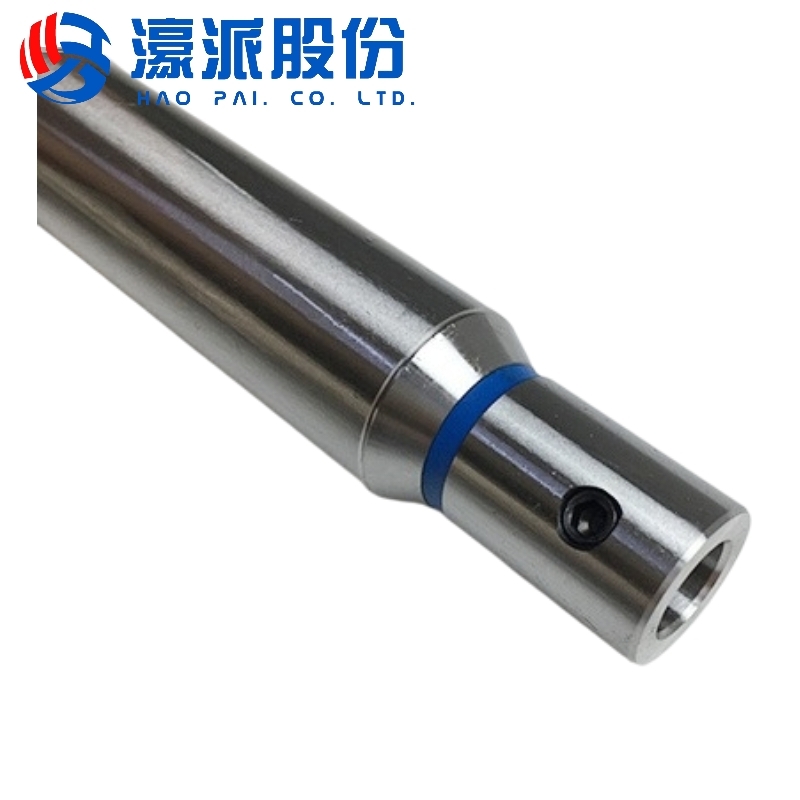

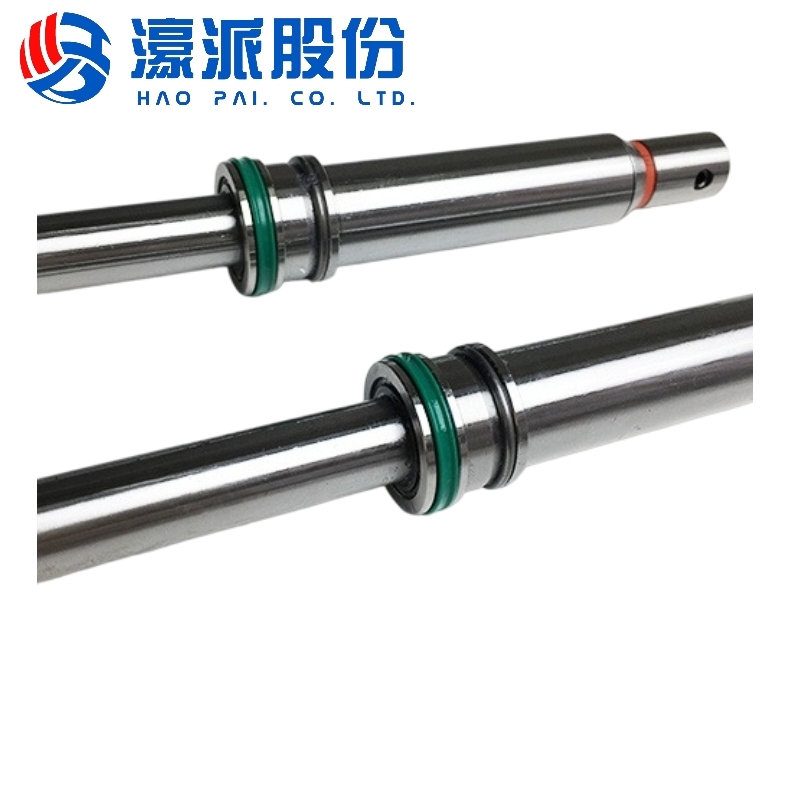

3、Precision machining process, ensuring basic precision

Through standardized processes such as CNC lathe machining and cylindrical grinder finishing, it ensures that the geometric accuracy of the shaft (such as cylindricity and circular runout) meets the design standards, providing a basic guarantee for the subsequent transmission accuracy of the equipment and avoiding assembly problems caused by machining errors.

4、Complete size specifications system, covering regular needs

Establishes a complete size system from small diameters (e.g., 8mm) to large diameters (e.g., over 100mm) and from short shafts (e.g., 50mm) to long shafts (e.g., over 500mm), covering the vertical transmission and support size needs of most industrial equipment and instruments, which can be purchased without special customization.

5、Basic protection treatment, extending storage and initial use life

All products undergo basic surface protection before leaving the factory: non-stainless steel models are mostly coated with anti-rust oil, and stainless steel models are subjected to surface passivation treatment, which can avoid rust during transportation and storage and ensure direct assembly and use after unpacking.

Product Technical Parameters

1 | Nominal Diameter | 8mm – 200mm |

2 | Effective Length | 50mm – 1000mm |

3 | Mounting Hole Diameter | M4 – M20/ φ5mm – φ30mm |

4 | Maximum Rotational Speed | 1000r/min – 5000r/min |

5 | Operating Temperature Range | -20℃ – 120℃;-40℃ – 200℃ |

6 | Surface Roughness | Ra 0.4μm – Ra 3.2μm |

Product Application Scope

1、General mechanical equipment fields

Suitable for the vertical transmission mechanism of general machine tools (such as lathes and milling machines), serving as a spindle or driven shaft to transmit torque; also applicable as a vertical guide shaft for printing machines and packaging machines to ensure coaxiality during equipment operation.

2、Precision instruments and electronic equipment fields

Adaptable to the vertical support shaft of precision measuring instruments (such as coordinate measuring machines), controlling radial runout through high-precision machining to ensure accurate measurement data; also usable as a vertical conveying shaft for semiconductor equipment to meet the requirements of dust-free and low-friction operation.

3、Automated production line and robot field

Used as the vertical lifting mechanism shaft in automated assembly lines, matching with cylinders or motors to realize vertical handling of workpieces; also serving as the core component of the Z-axis in industrial robots (such as SCARA robots) to support the vertical movement of end effectors and ensure motion stability.

4、Heavy machinery and engineering machinery fields

Suitable for the vertical load-bearing shafts of cranes and elevators, using high-strength alloy steel to bear axial heavy loads; also applicable to the vertical shafts of hydraulic actuators in excavators and loaders, providing stable transmission and support under complex working conditions.

5、Medical device field

Used for the vertical adjustment shafts of medical imaging equipment (such as CT scanners and X-ray machines), controlling the smooth lifting of equipment components through a precision structure; also serving as the vertical drive shaft of rehabilitation equipment (such as electric lifting hospital beds) to meet the requirements of low noise and high safety.

Product Description

1、Adaptation description according to device functional requirements

It accurately matches different functional positions based on the two core needs of equipment: "vertical transmission" and "vertical support":

When the equipment needs to transmit torque (such as machine tool spindles, robot Z-axis), its standardized keyway/thread structure can stably connect transmission components, and the high-strength material can bear the corresponding load to avoid transmission slippage or structural deformation;

When the equipment only needs guiding support (such as lifting rods of automated production lines, instrument positioning shafts), its precision-machined cylindricity and low-roughness surface can reduce the fitting gap with bearings, ensuring the stability of vertical movement without additional vibration interference.

2、Described by the adaptability of working condition environment

It can flexibly adapt to working condition parameters such as temperature, corrosion, and load intensity, with a clear adaptation logic

In terms of temperature, conventional materials (45# steel, 40Cr) can work stably at -20℃~120℃, meeting the needs of most industrial workshop environments; special stainless steel materials (316) can be extended to -40℃~200℃, adapting to special high and low temperature scenarios (such as cold chain equipment, high-temperature drying equipment);

In terms of corrosion, galvanized/Dacromet-treated mandrels can cope with slightly humid and dusty environments (such as food processing workshops), while 304/316 stainless steel can be used for a long time in moderately corrosive environments (such as chemical auxiliary equipment, medical cleaning scenarios) without rust risk;

In terms of load, small-diameter (≤20mm) mandrels are suitable for light loads below 5kN (such as small instruments), medium-diameter (20mm~80mm) for medium loads of 5kN~25kN (such as machine tools), and large-diameter (≥80mm) with alloy steel materials can bear heavy loads of 25kN~50kN (such as lifting equipment).

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.