Products

- Cutting Equipment Parts

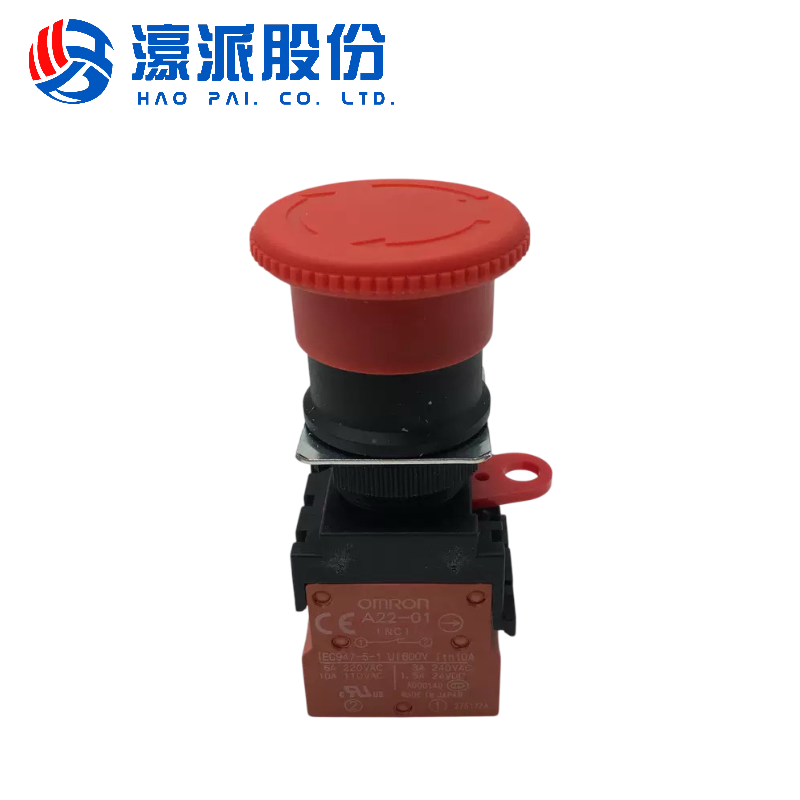

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

Wrapping Machine Cutters

- haopai

- Guangdong,China

- 7-15 days

- 50 per month

- Inner hole 20mm

Product Advantages and Features

1.High-Precision Cutting Technology

Micron-level accuracy (±0.05mm) ensures clean, burr-free edges

Laser/CCD vision positioning for real-time monitoring and automatic alignment

Handles ultra-thin materials (e.g., 5μm battery separators, optical films)

2.Intelligent Control System

PLC + touchscreen interface with one-touch parameter setting and recipe storage

Auto tension control (servo motor + magnetic powder brake) prevents film stretching

Smart alignment system (photoelectric/CCD detection) ensures material tracking

IoT-enabled for remote monitoring, fault alerts, and production analytics

3.High-Efficiency Production

Cutting speeds up to 800m/min (high-end models like KAMPF MSL series)

Dual-station rewinding enables non-stop roll changes, boosting productivity by 50%

Durable blade systems (alloy steel/ceramic) with extended lifespan and easy replacement

4.Multi-Functional Adaptability

Versatile configurations: Supports rotary, shear, pneumatic, and ultrasonic cutting

Wide material compatibility:

Plastic films (PE/PP/PET/BOPP)

Foils, non-wovens, composite materials

Specialty films (graphene, breathable membranes)

Modular design: Optional dust removal, static elimination, or inline inspection.

5.Energy-Saving & Eco-Friendly

Low-power drives (servo systems reduce energy use by 30%)

Dust-free operation (optional suction for cleanroom environments)

Quiet operation (<65dB), compliant with environmental standards

Product Technical Parameters

Item | Specification Range | Notes | |

Basic Parameters | Machine Width | 600-2500mm | Custom wider models available |

Max Unwinding Diameter | Φ800-1500mm | Air shaft/mechanical shaft options | |

Max Rewinding Diameter | Φ600-800mm | Auto-unloading models up to Φ1000mm | |

Slitting Speed | 10-800m/min | Standard models: 200-400m/min | |

Slitting Accuracy | ±0.05mm (Premium)/±0.1mm (Economy) | Laser thickness gauge calibrated | |

Cutting System Parameters | Cutting Method | Rotary/Shear/Ultrasonic/Pneumatic (Optional) | |

Blade Material | Carbide/Ceramic/Diamond Coating (For special materials) | ||

Min. Slitting Width | 2mm (Rotary)/0.5mm (Shear) | ||

Blade Shaft Speed | 0-3000rpm (Variable frequency drive) | ||

Product Application Scope

The application of bag covering machine film cutters in the wood industry mainly focuses on the surface treatment of decorative boards. Through high-precision cutting technology, it provides efficient and beautiful surface coating solutions for wooden materials, helping to promote efficient production

Equipment case: Production of edge banding, cutting ABS/PMMA edge banding (width 15-45mm)

Product Description

Parameter | Wood Industry Specs | Vs. Packaging Film Standards |

Cutting Method | Heavy-duty rotary blade + preheating | Standard rotary blade sufficient |

Tension Control | Dual-stage system (for uneven substrates) | Single-stage adequate for flat films |

Dust Removal | High-pressure air knife + cyclone system | Basic dust removal sufficient |

Alignment | ±0.3mm tolerance | ±0.1mm for optical films |

In the field of wood surface treatment, the selection of professional film separators directly determines production efficiency, material utilization, and product aesthetics. They have high-precision cutting technology, intelligent automation control, efficient and stable production, multi-functional adaptability, and can be used for multiple purposes. Through intelligent transformation, they bring continuous cost reduction and efficiency improvement.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.