Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

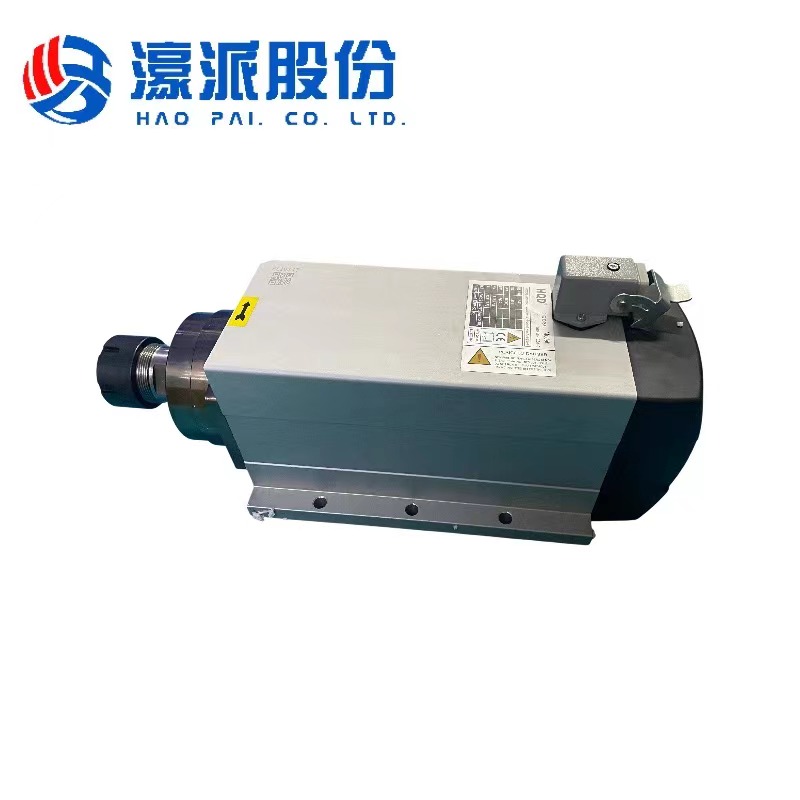

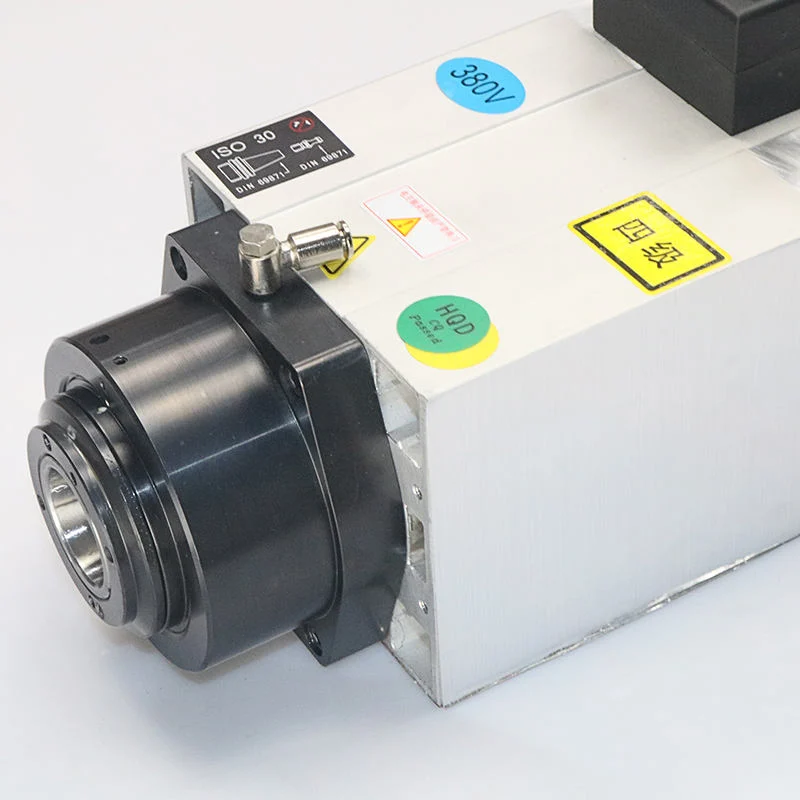

cnc-motors-high-speed-precision-spindle-hqd-gdf60

- HQD

- China

- 2-3mouths

- 10 units per year

- GDF60-18Z-6.0

- 13kg

Product Advantages and Features

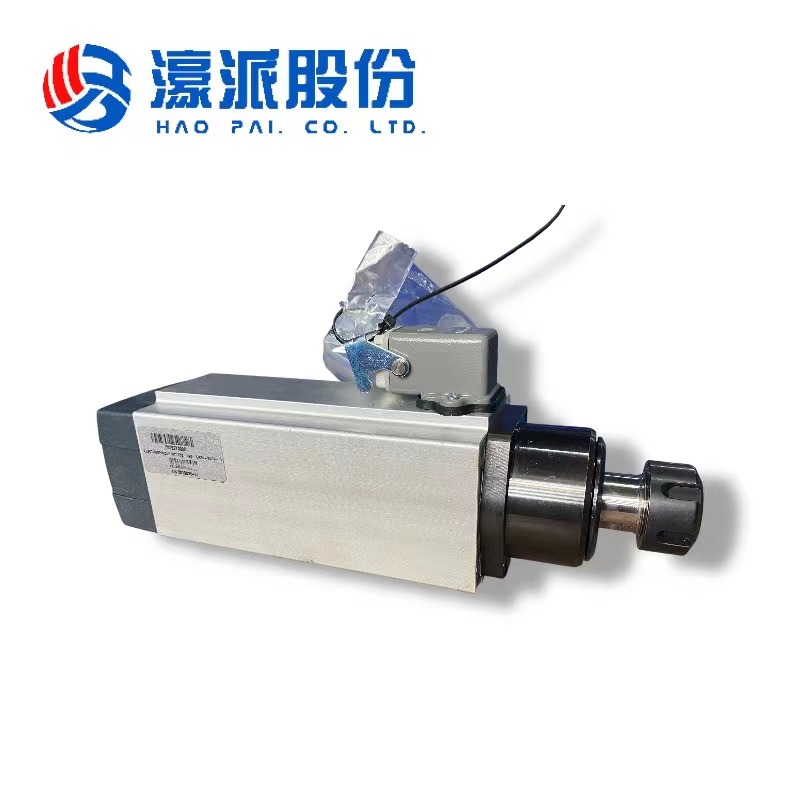

1. High Power Density and Stable Output:With a rated power of 6.0kW and an optimized electromagnetic design, it achieves high torque output (rated torque ≥18N·m) in a compact size of 60mm diameter. It can meet medium and heavy-duty processing needs such as wood carving and light metal cutting, with no obvious power attenuation during long-term operation, ensuring consistent processing accuracy.

2. Excellent High-Speed and Low-Noise Performance:The maximum speed can reach 18,000r/min (the mark "18Z" corresponds to high-speed characteristics). Equipped with a precision dynamic balancing process (dynamic balance grade ≤G1), the vibration amplitude during operation is <0.02mm, and the noise is controlled below 75 decibels. It not only improves processing efficiency but also optimizes the workshop operating environment.

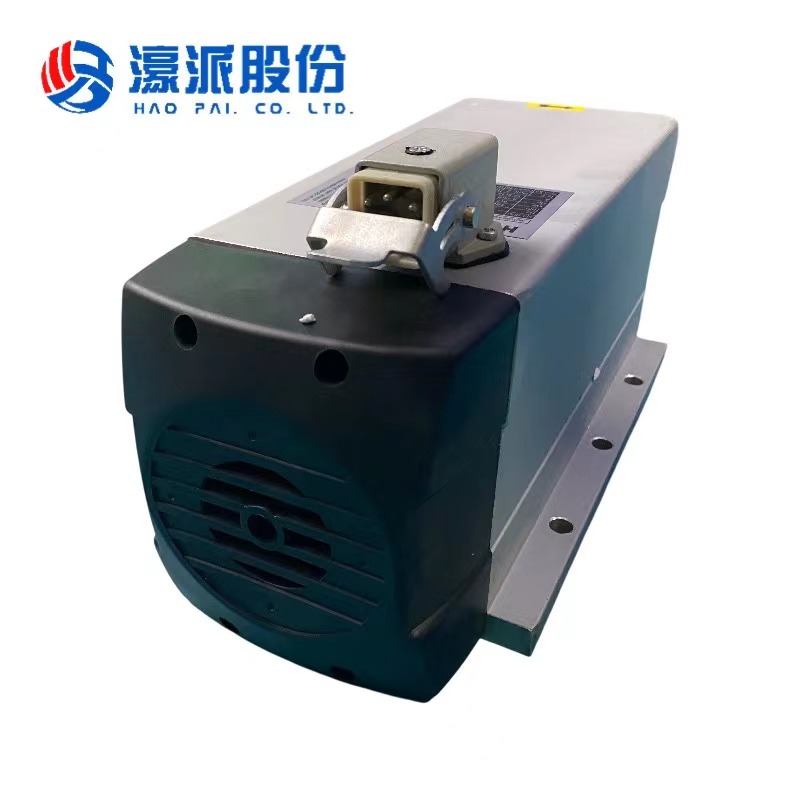

3. Strong Heat Dissipation and Durable Structure:Adopting a fully enclosed aluminum casing + built-in air duct design, the heat dissipation efficiency is 30% higher than that of traditional strctures, allowing continuous operation in an environment of -10℃-40℃. The bearings are high-precision angular contact ball bearings, combined with high-temperature grease, with a service life of more than 8,000 hours, reducing equipment maintenance frequency.

4. Flexible Adaptation and Safety Protection:It supports three-phase 380V industrial power input and can be directly connected to mainstream CNC systems (such as Siemens, Fanuc), adapting to various equipment such as woodworking machinery and CNC milling machines. It is equipped with three-fold protection functions of overcurrent, overload, and overheating. When the motor temperature exceeds 120℃ or the current is abnormal, it automatically shuts down to prevent motor burnout.

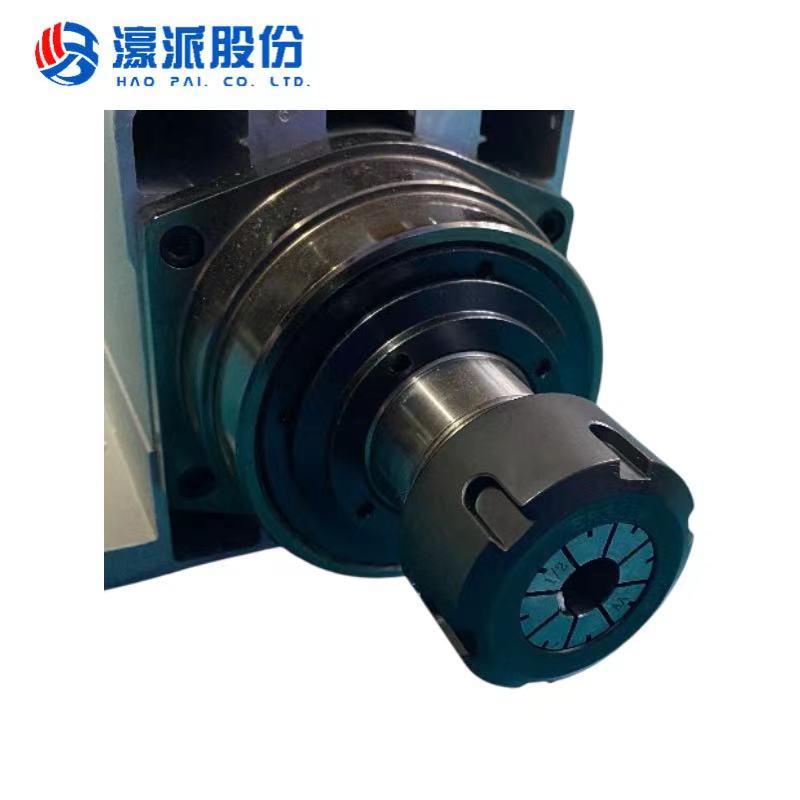

5. Guarantee for High-Precision Processing:The rotor adopts an integrated forging process with a coaxiality error ≤0.005mm. Combined with a high-precision encoder (resolution 1024p/r), it can realize closed-loop speed control. The feed accuracy error during processing is <0.01mm, which is especially suitable for processing parts with high surface finish requirements (such as solid wood carving and precision milling of metal molds).

Product Technical Parameters

Model | HQD GDF60-18Z-6.0Product Type: Spindle Motor |

Rated Power | 6.0kWRated Torque: ≥18N·mMaximum Speed: 18000r/min |

Spindle Diameter: | 60mmCasing Material: Fully Enclosed Aluminum |

Input Power: | Three-Phase 380V Industrial PowerCompatible Systems: Mainstream CNC Systems (Siemens, Fanuc, etc.) |

Operating Temperature | -10℃-40℃Protection Functions: Overcurrent, Overload, Overheating (Auto Shutdown when Temperature>120℃) |

Dynamic Balance Grade: | ≤G1Service Life: ≥8000 Hours |

Product Application Scope

1. Suitable for Automatic Woodworking Engraving Machines: It can drive the equipment to perform 3D relief and fine carving processing on hard woods such as oak and walnut. Relying on 6.0kW rated power and 18N·m torque, it ensures sufficient power for hard wood carving; the high rotation speed of 18,000r/min combined with ≤G1 grade dynamic balance performance can make the edges of carved patterns smooth and burr-free, meeting the processing standards of high-quality woodworking decorative parts.

2. Suitable for CNC Panel Saws: Used for straight cutting and special-shaped cutting of man-made boards such as particleboard and MDF. The strong torque can ensure smooth cutting without jamming; the IP54 dust-proof and splash-proof grade can block a large number of wood chips generated during cutting from invading the interior of the motor, and the forced air cooling design prevents the motor from overheating and shutting down due to long-term batch panel cutting, maintaining the continuity of operations.

3. Suitable for Woodworking Milling Machines: Designed for milling of solid wood mortise and tenon structures, forming of wood mouldings and edge trimming of boards. The combination of high-precision angular contact ball bearings (coaxiality error ≤0.005mm) and 1024p/r encoder can realize millimetre-level precision control, greatly improving the fit of mortise and tenon connections and the flatness of wood mouldings, meeting the needs of fine processing.

4. Suitable for Woodworking Sanders: Used for fine sanding of solid wood surfaces and polishing after veneering of man-made boards. The low vibration (<0.02mm) characteristic of the motor can ensure the smoothness of the processed surface and avoid uneven sanding or polishing caused by vibration; at the same time, it is compatible with the continuous operation mode of the equipment, ensuring the stability of surface quality during batch processing.

5. Suitable for Automated Woodworking Production Lines: Since it supports connection with mainstream CNC systems such as Siemens and Fanuc, it can be conveniently integrated into automated production lines to realize the linkage of multiple processes including carving, cutting, milling and sanding. It can reduce manual intervention, improve the connection efficiency of various processes, and at the same time ensure the processing consistency of products in different batches, helping the large-scale woodworking production.

Product Description

Key Performance | Woodworking Application |

6.0kW Rated Power + 18N·m Torque | Drives engraving machines to process hard wood; enables panel saws to cut thick man-made boards |

18000r/min High Speed + ≤G1 Dynamic Balance | Fine carving and relief on engraving machines, ensuring smooth patterns |

IP54 Protection Class + Forced Air Cooling | Dust and wood chip resistance for panel saws and sanders; no high-temperature shutdown during continuous operation |

High-Precision Bearings (Coaxiality ≤0.005mm) + Encoder | Mortise-tenon structure and wood moulding processing on milling machines, with mm-level precision control |

Compatibility with Mainstream CNC Systems | Integration into automated woodworking production lines for multi-process linkage |

120℃ Overheating Protection | Prevents motor burnout during batch processing on all woodworking equipment, improving safety |

The HQD GDF60-18Z-6.0 Spindle Motor is a high-efficiency power core designed specifically for woodworking machinery. With high power, high speed and strong environmental adaptability, it perfectly adapts to the entire process of solid wood and man-made board processing. Its 6.0kW rated power and 18N·m torque can easily drive automatic woodworking engraving machines to complete 3D reliefs and fine carvings on hard wood (oak, walnut). The 18,000r/min high speed combined with ≤G1 dynamic balance ensures smooth, burr-free edges of carved patterns. The IP54 dust-proof and splash-proof grade and forced air cooling design enable stable operation in scenarios with large amounts of wood chips, such as CNC panel saws and woodworking sanders, avoiding dust intrusion and high-temperature shutdowns. The 120℃ overheating protection function further ensures the safety of continuous batch processing.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services.We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.