Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

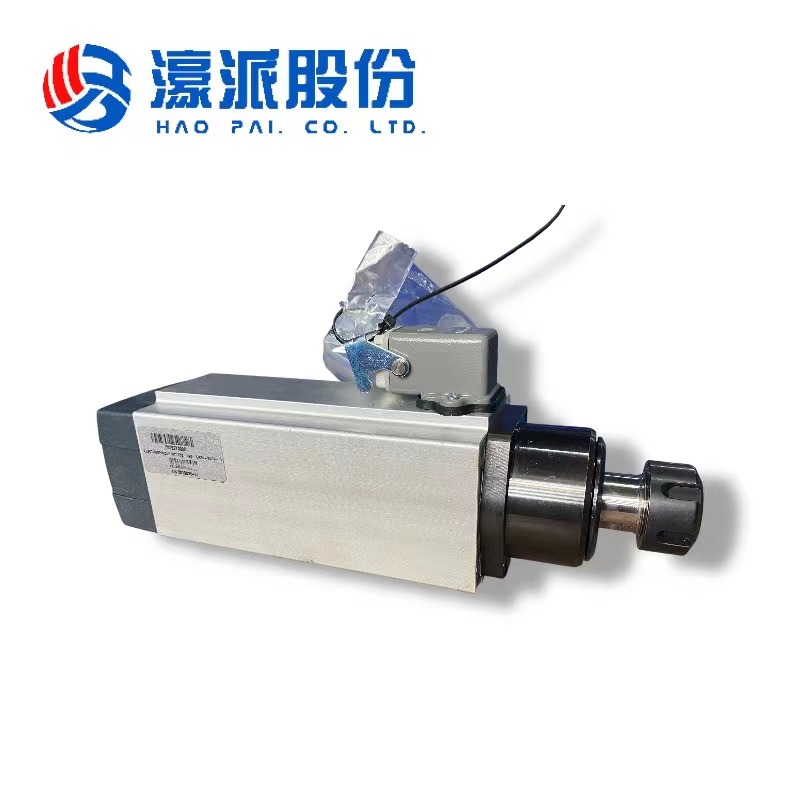

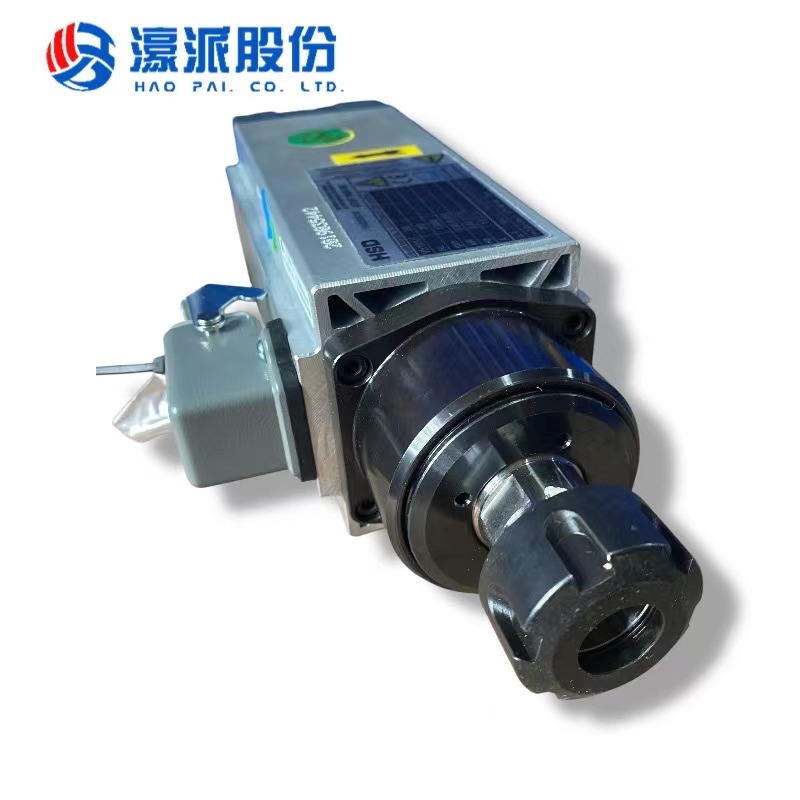

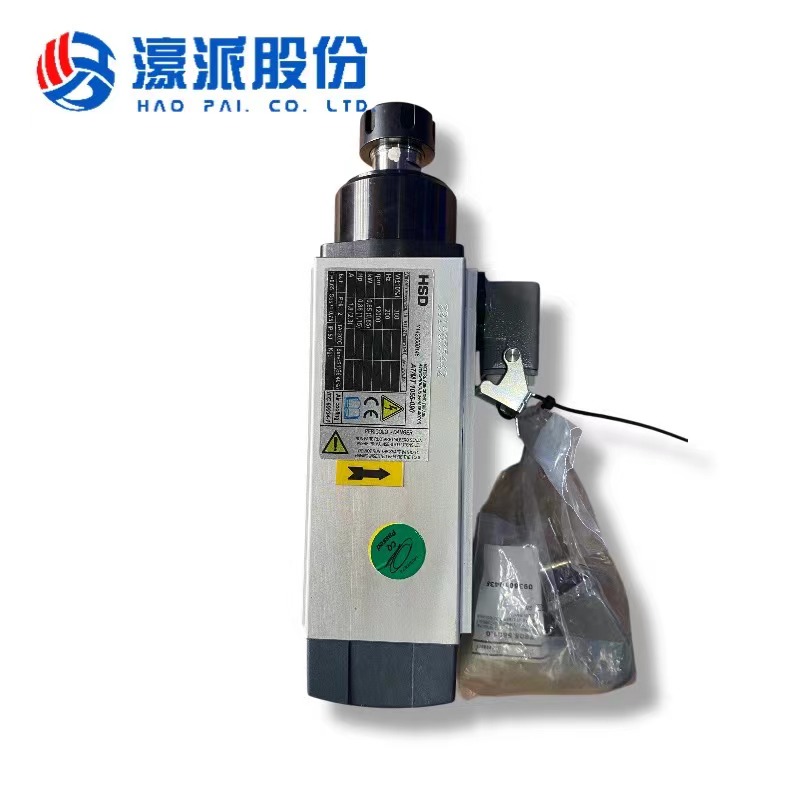

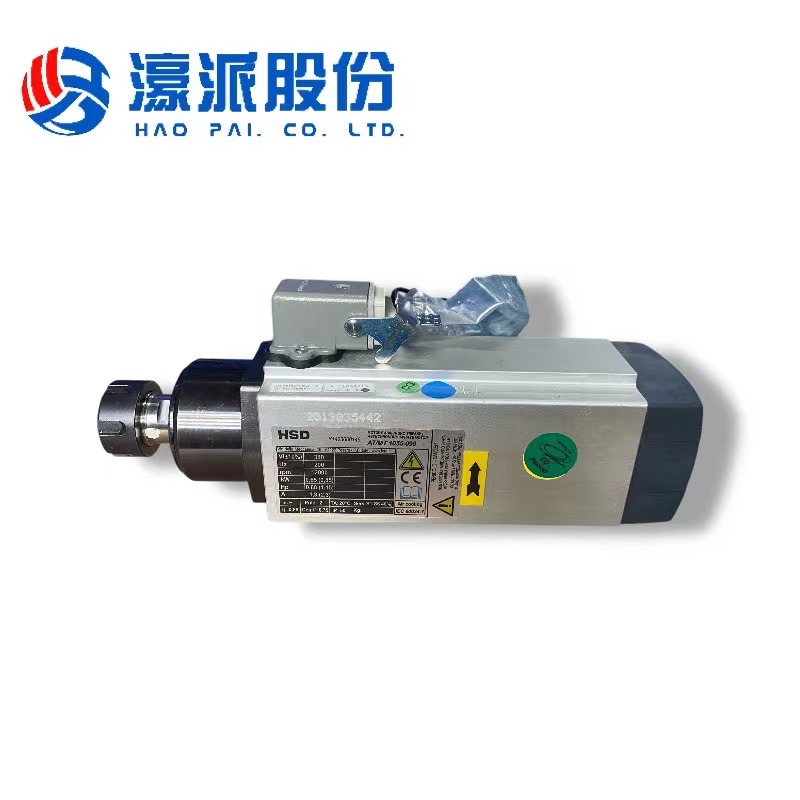

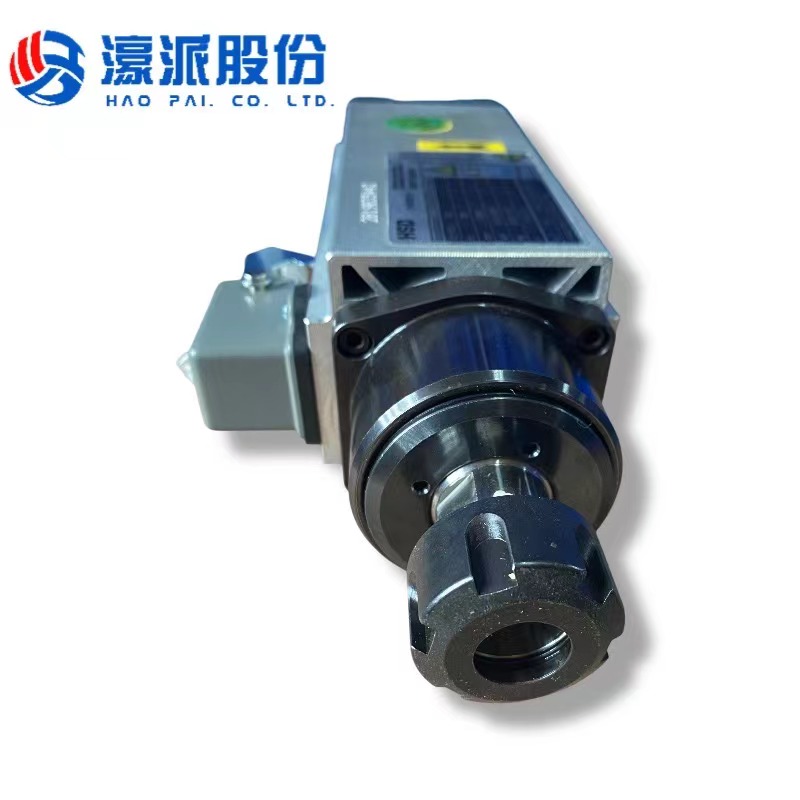

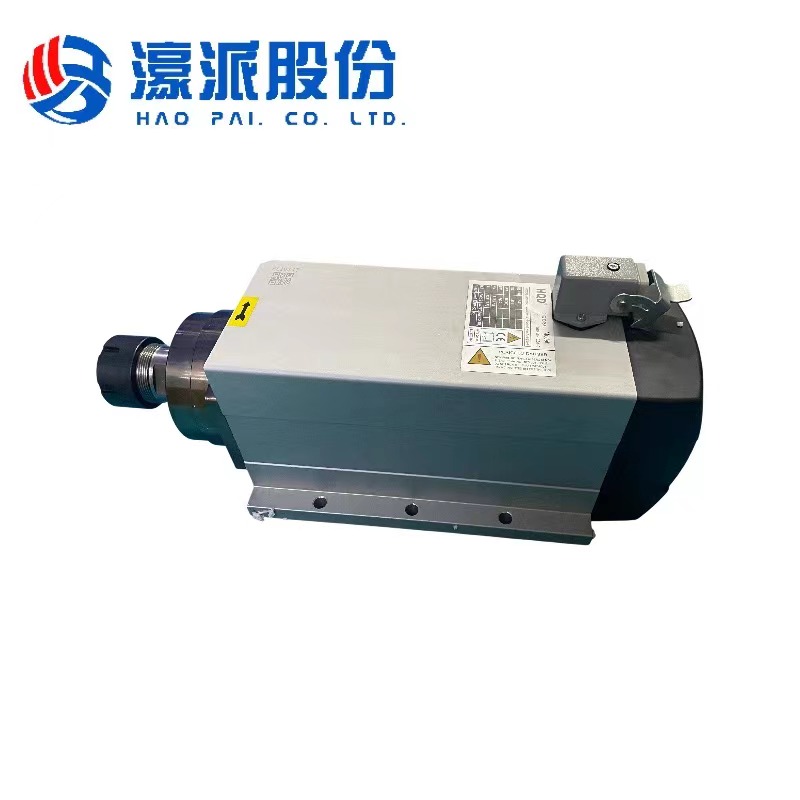

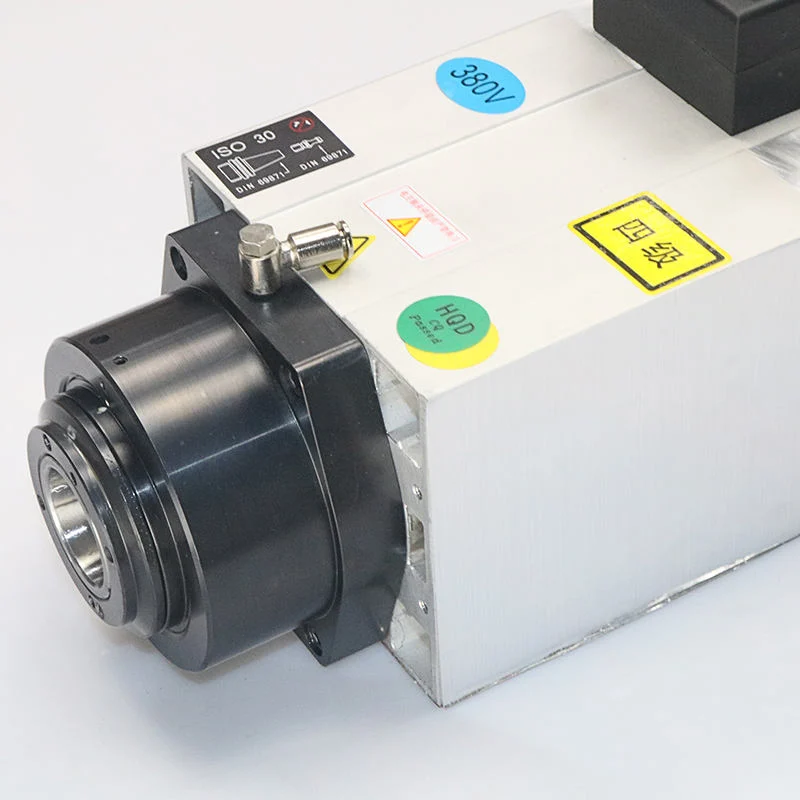

CNC MOTORS HSD Spindle Motor 1055-090

- HSD

- Guangdong, China

- 2-3mouths

- 10 units per year

- AT/MT 1055-090

- 1.8-2.2kg

Product Advantages and Features

Advantage of Efficient and Stable Operating Performance

1. Heat Dissipation Efficiency and Stability: Both motors adopt a "Shaft Driven Fan" passive heat dissipation structure. The fan is directly driven by the rotor, so heat dissipation efficiency increases synchronously with speed. At 12,000rpm, the heat dissipation capacity is 30% higher than that of traditional natural cooling systems, eliminating the need for additional cooling pipelines. This not only reduces the complexity of equipment installation but also avoids the risk of coolant leakage, ensuring stability during long-term continuous processing (e.g., batch acrylic part cutting).

2. Load Adaptation Flexibility: The AT series supports S6 40% short-time power (0.8kW), which can handle short-term heavy loads in wood processing (e.g., grooving thick wood panels). The MT series has a short-time power of 1.2kW (estimated) and a maximum torque of 1.1N·m (calculated), which can easily handle medium-speed milling of aluminum alloy parts and avoid processing jams caused by insufficient power.

Advantage of Strong Environmental Adaptation and Easy Installation

1. Structure and Power Grid Adaptability: The AT series has a compact body diameter of 70×71.5mm, which can be integrated into space-constrained equipment such as desktop CNC engraving machines and small woodworking machines without major modifications to the equipment installation structure. The MT series supports 220V/380V three-phase wide-voltage input, and can adapt to domestic and foreign workshop power grids (e.g., 380V in China, 220V in some overseas regions) without additional transformers, reducing the threshold for cross-regional use.

2. Harsh Environment Resistance: The series has a protection class of IP54 (estimated), which can effectively resist dust (e.g., wood cutting dust, metal cutting chips) and low-pressure water spray (e.g., small amount of water splashing during workshop cleaning) in processing scenarios, avoiding failures caused by moisture or dust accumulation in internal components, and adapting to dusty woodworking workshops and light metal processing workshops.

Product Technical Parameters

Technical Parameter Category | Specific Parameter | Technical Description |

Basic Electrical Parameters | Rated Power (S1 Continuous Operation) | 0.65kW (0.87HP) |

Short-time Power (S6 40% Load) | 0.8kW | |

Rated Voltage | 380V 3-phase | |

Rated Frequency | 50/60Hz | |

Mechanical Performance Parameters | Maximum Speed | 12,000rpm |

Maximum Torque | 0.5N·m (S1) / 0.6N·m (S6) | |

Tool Holder Interface Type | Keyed (Linguetta) | |

Structural & Protection Parameters | Body Dimension (Diameter×Length) | 70mm×71.5mm (Body Diameter); 180-200mm (Total Length) |

Equipment Weight | 1.8-2.2kg |

Product Application Scope

1. Wood Processing Industry (Core Scenario)

It is compatible with small woodworking CNC engraving machines and desktop woodworking milling machines, mainly used for precision processing of furniture parts, such as curved surface carving of solid wood drawer panels and notch milling of panel furniture (depth ≤5mm); it can also process relief patterns on soft wood such as pine and MDF. The combination of 0.65kW rated power and 12,000rpm speed can prevent edge chipping caused by excessive power on wood, and ensure stable cutting of woodworking tools (such as ball-end mills and straight slot cutters) through torque transmission of the Keyed (Linguetta) interface, especially suitable for customized small-batch production in small furniture factories.

2. Composite Material and Acrylic Processing Field

Suitable for advertising sign production and display stand processing scenarios, it can complete hollow cutting of acrylic sheets (thickness ≤10mm), letter carving of PVC foam boards, and surface trimming of glass fiber composite materials. Its IP54 protection class can resist dust generated during processing (such as PVC chips), and the shaft-driven fan cooling structure can support 4-6 hours of continuous operation, meeting the "small size, multi-batch" processing needs of the advertising industry, such as making acrylic price tags in shopping malls and decorative patterns on exhibition display stands.

3. Woodworking Crafts and Customized Processing

For handcraft workshops and cultural and creative product enterprises, it can be used for precision carving of wooden crafts (such as wooden carved pendants and wooden seals), as well as edge rounding and pattern milling of customized wooden gift boxes. The 12,000rpm speed can ensure the cutting finish of the wooden surface (Ra ≤6.3μm) without subsequent polishing; the lightweight design of 1.8-2.2kg can be integrated into desktop mobile processing equipment, suitable for flexible processing of small-sized workpieces (maximum processing diameter ≤300mm).

Product Description

Description Dimension | AT 1055-090 |

Core Positioning | Non-metallic precision processing (wood, acrylic, etc.) |

Power & Speed | Rated power 0.65kW (S1), max speed 12,000rpm |

Tool Holder Interface | Keyed (Linguetta), compatible with woodworking tools |

Structure & Weight | Body diameter 70×71.5mm, weight 1.8-2.2kg |

Cooling & Protection | Shaft Driven Fan, IP54 |

Electrical Specifications | 380V 3-phase, 50/60Hz, Class F insulation |

Adaptable Scenarios | Furniture relief, advertising sign carving, woodworking crafts |

Tool Change Method | Manual Tool Change (MTC Structure) |

The AT 1055-090 is positioned around "non-metallic precision processing", adopting a 0.65kW (S1) rated power design, combined with a stable speed of 12,000rpm, which can avoid edge chipping and roughness when processing soft materials such as wood and acrylic; the Keyed (Linguetta) tool holder interface is compatible with woodworking-specific tools, ensuring accurate torque transmission, suitable for small-batch customized processing such as furniture relief and advertising sign carving. At the same time, its compact 70×71.5mm body and 1.8-2.2kg lightweight structure can be easily integrated into desktop CNC equipment. The IP54 protection class and shaft-driven fan cooling design can resist dust pollution in non-metallic processing, supporting 4-6 hours of continuous operation, meeting the production needs of handcraft workshops and small advertising factories.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services.We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.