Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

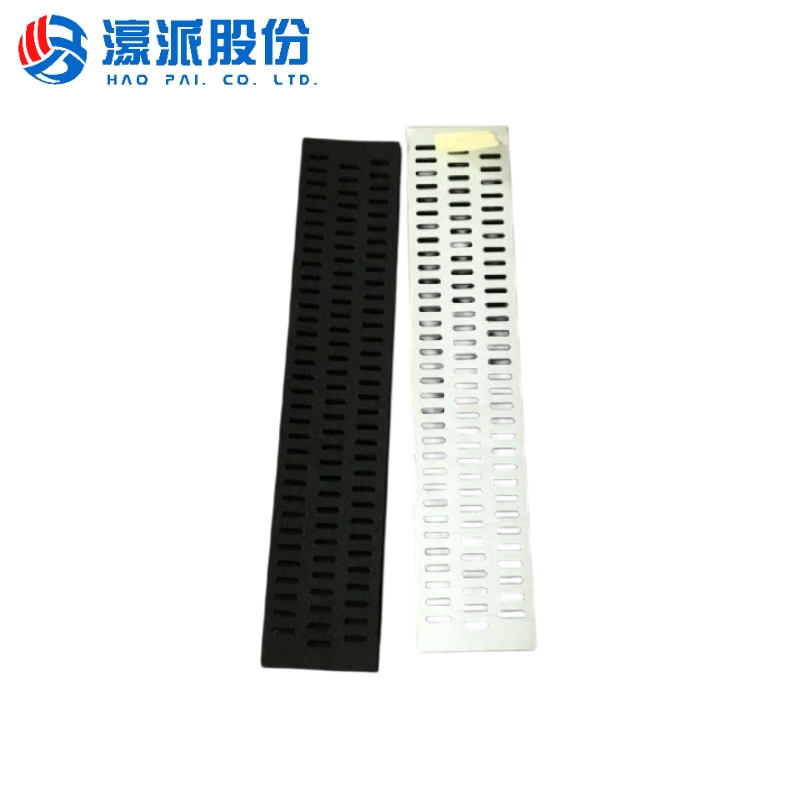

Suction Cup Pad/Gasket

- haopai

- Guangdong, China

- 5-10days

- 100 per month

- 4011110079

- 125*75*17

Product Advantages and Features

1.Super strong adsorption, secure and reliable.

The suction cup pad adopts an innovative negative pressure adsorption structure. When it comes into contact with smooth surfaces (such as glass, tiles, metal panels, etc.), simply pressing it gently can expel the air inside the suction cup, forming a strong negative pressure sealed space. Its adsorption force is far superior to that of ordinary suction cup products. Even when hanging items weighing less than 5kg (such as kitchen storage baskets, bathroom storage racks), it can remain stable for a long time without falling off due to slight collisions or vibrations, effectively solving the pain point of "easy slipping" of traditional suction cups and providing reliable protection for item fixation.

2.Premium material, safe and durable

The product is made of food-grade silicone or high-elastic rubber material, which does not contain harmful substances such as formaldehyde and heavy metals, and has no odor emission. It can directly contact tableware, baby products, etc., meeting the needs of safe family use. At the same time, the material has excellent high and low temperature resistance (-20℃~80℃), and is not easy to deform or crack under the environment of hot sun exposure in the car in summer and low temperature in winter; it also has strong anti-aging ability, and can still maintain good elasticity and adsorption after long-term use (up to 2-3 years under normal use). It can be used continuously after repeated cleaning, and its cost-effectiveness is far higher than that of disposable suction cup products.

3.No drilling required, easy and damage-free installation.

The suction cup pad adopts a drill-free design, which does not require tools such as electric drills and screwdrivers, nor does it need to drill holes on the surface of walls, desktops and furniture, avoiding damage to the decoration and the appearance of items. During installation, you only need to wipe the contact surface clean, align the suction cup with the position and press it to complete the fixation, and the whole process takes no more than 30 seconds; when disassembling, you only need to gently lift the edge of the suction cup to release the internal negative pressure, and then you can easily take it off without leaving residues such as glue marks and scratches on the contact surface. It is suitable for various scenarios such as rental houses and new houses, solving the problem of "damaging the surface and being difficult to restore" in traditional drilling installation.

Product Technical Parameters

Parameter | Parameter Name | Specification Range/Typical Value | Unit | Remarks |

Pad Thickness | 3-8 | mm | Different thicknesses adapt to different adsorption pressure requirements | |

Edge Shape | Rounded Corner, Right Angle | - | Rounded corners reduce collision wear; right angles fit compact installation | |

Main Material | Nitrile Rubber (NBR), Silicone | - | NBR is oil-resistant; silicone is high/low temperature-resistant, food-grade optional | |

Hardness (Shore A) | 50-70 | HA | Hardness 50-60: softer (high sealing); 60-70: tougher (high wear resistance) | |

Tensile Strength | ≥8 | MPa | Measures the material's resistance to fracture |

Product Application Scope

Suction cup gaskets (also referred to as vacuum adsorption gaskets) achieve adsorption and fixation by utilizing atmospheric pressure, and they have an extremely wide range of applications.

As the core contact component of vacuum suction cups, the Suction Cup Rubber Pad can be accurately adapted to the vacuum suction cup assemblies of robotic arms, automatic sorters, and material handling equipment. It is used for the adsorption and transfer of precision components such as chips and circuit boards in the electronics industry, as well as metal stampings and plastic trim panels in the automotive manufacturing field. The oil-resistant property of its nitrile rubber (NBR) material can handle the grabbing of materials with slight oil contamination in industrial environments; the silicone material version is suitable for working conditions requiring high and low temperature resistance (such as the transfer of auto parts before high-temperature coating). Meanwhile, different hardness (50-70HA) options can match the differentiated adsorption needs of thin, fragile parts and heavy components, avoiding material damage or falling off.

Product Description

Description Dimension | Detailed Explanation |

Core Product Definition | Suction cup gaskets are core elastic contact components of vacuum adsorption equipment. They form a sealed space by fitting the surface of materials, and realize material adsorption and fixation through the pressure difference between atmospheric pressure and vacuum environment. They integrate sealing, buffering and anti-slip functions, and are key accessories to ensure the stable operation of vacuum suction cups. |

Core Structure & Material | 1. Structure: Mostly circular/square sheet design, with rounded corners (anti-collision) or sealing lips (enhanced sealing) on the edges; some have mounting positioning holes (facilitating assembly with the suction cup main body);2. Material: Mainstream materials are nitrile rubber (NBR) and silicone; special materials such as fluororubber can be customized. Different materials correspond to differentiated performances (e.g., NBR is oil-resistant, silicone is high/low temperature-resistant/food-grade). |

Core Performance Features | 1. Sealing Performance: Excellent material elasticity, low compression set (≤20%@70℃×22h), which can closely fit smooth/micro-curved surfaces to avoid vacuum leakage;2. Adaptability: Thickness 3-8mm and diameter 50-300mm optional, compatible with different specifications of vacuum suction cups; hardness 50-70HA adjustable (soft for high sealing, hard for high wear resistance);3. Durability: Tensile strength ≥8MPa, tear strength ≥25kN/m, anti-aging life ≥3 years (room temperature), capable of withstanding temperature range of -60℃-200℃ (silicone material);4. Safety Performance: Food-grade models comply with FDA certification, general models comply with RoHS certification, odorless and anti-pollution; some flame-retardant (V0/V1 grade) materials are optional. |

In the fiercely competitive woodworking manufacturing industry, As a core elastic accessory of vacuum adsorption equipment, the suction cup gasket takes "sealing + buffering + adaptation" as its core value. By virtue of the elastic properties of materials such as nitrile rubber (NBR) and silicone, it fits the surface of materials to form a sealed space, and realizes stable adsorption through the pressure difference between atmospheric pressure and vacuum. It is a key component to ensure the reliable operation of vacuum suction cups. Its core advantages are reflected in three aspects: first, diversified performance — it has excellent sealing performance (compression set ≤20%), strong adaptability (thickness 3-8mm, diameter 50-300mm adjustable, hardness 50-70HA optional), and good durability and weather resistance (temperature resistance range -60℃-200℃, anti-aging life ≥3 years); second, safety and compliance — food-grade models comply with FDA certification, general models comply with RoHS certification, and some flame-retardant materials are optional, adapting to safety requirements of multiple scenarios; third, wide application — it covers fields such as industrial automation (handling of precision components/auto parts), logistics packaging (sorting of cartons/cold chain materials), food and medical (transfer in clean environments), and household equipment (vacuum hooks/cleaning robots). It not only ensures stable adsorption to prevent materials from falling off, but also buffers pressure to protect material surfaces, providing efficient and safe support for vacuum adsorption operations in various industries.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.