Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

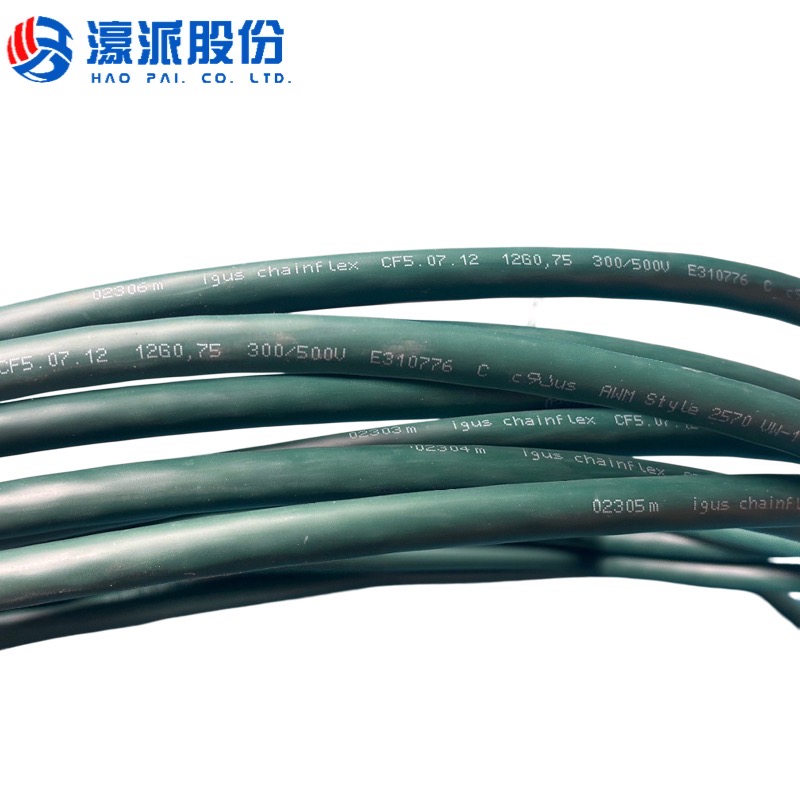

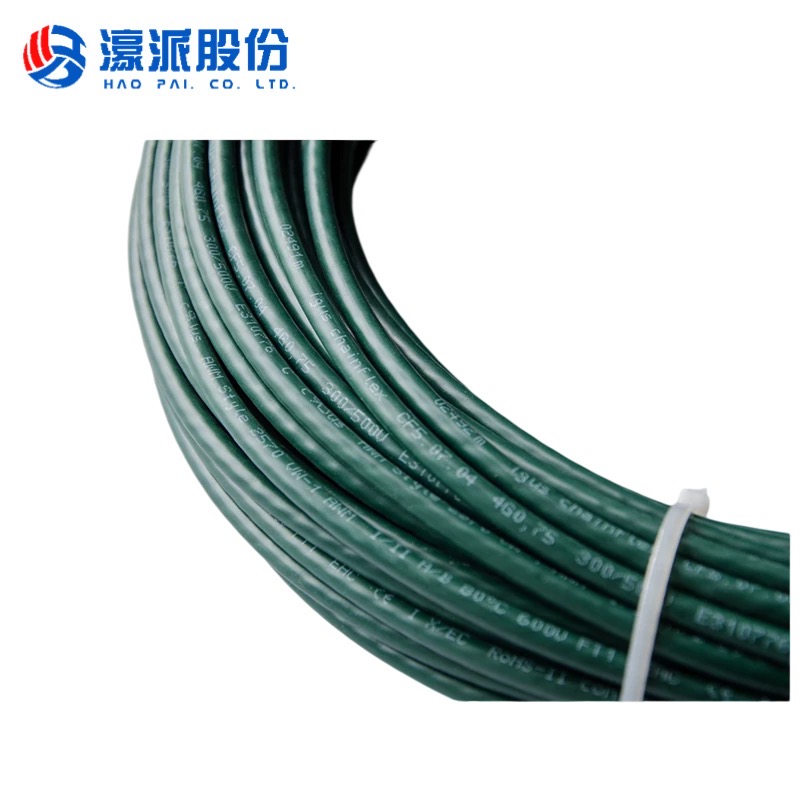

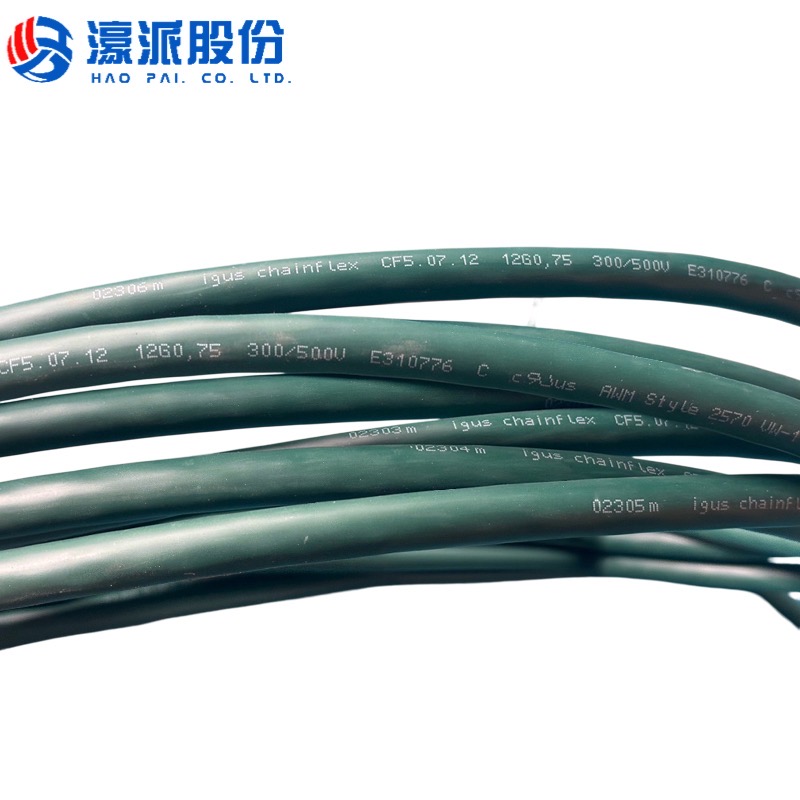

Flexible Cable

- igus

- Germany

- 5-10days

- 100 per month

- CF5.07.12

- 12*0.75

Product Advantages and Features

1.Highly Flexible and Bend-Resistant Structure

Ultra-fine stranded copper conductors with optimized lay length design, supporting over 5 million reciprocating bending cycles.*

2.Dual Shielding for Anti-Interference

Foil + tinned copper braided double-layer shielding provides 360° full electromagnetic protection (EMI/RFI), ideal for sensitive signal transmission

3.Oil-Resistant and Abrasion-Resistant Jacket Mater

High-quality PUR (polyurethane) jacket with oil resistance (ISO 1817 compliant), tear resistance, and microbial corrosion resistance

4.Wide Temperature Adaptability

Operating temperature range: -40°C to +90°C (PUR jacket), suitable for alternating high/low temperature environments.*

5.High-Efficiency Transmission and Durability

Low capacitance design (<90 pF/m) reduces signal attenuation, supporting high-frequency data transmission (up to 100 MHz)

Product Technical Parameters

Parameter Category | Parameter Name | English Specification/Value | Remarks |

Basic Specifications | Cable Model | CF5.07.12 | Exclusive product model for specification identification and selection |

Conductor Structure | 7 Strands × 0.26mm (Tinned Copper) | Tinned copper conductor enhances oxidation resistance and soldering performance; 7-strand stranded design improves flexibility | |

Conductor Cross-Sectional Area | 0.35 | Suitable for low-to-medium current transmission scenarios, meeting equipment power supply or signal transmission needs | |

Insulation Material | Polyvinyl Chloride (PVC) | Excellent insulation performance, aging-resistant and wear-resistant, complying with general cable insulation standards | |

Minimum Insulation Thickness | 0.25 | Ensures electrical insulation strength and prevents leakage risks | |

Maximum Cable Outer Diameter | 1.8 | Thin-diameter design, suitable for narrow installation spaces (e.g., internal wiring of equipment, dense wire harness scenarios) | |

Cable Color | Black (Customizable to Other Colors) | Black as standard color; customizable to red, blue, etc., for wiring identification based on customer needs | |

Electrical Performance | Rated Voltage (AC) | 300/500 | AC rated voltage, suitable for low-voltage electrical systems (e.g., home appliances, instrument power supply) |

Rated Temperature | 80 | Upper limit of long-term safe operating temperature; load reduction required if exceeded | |

Maximum DC Resistance of Conductor at 20℃ | 53 | Low-resistance characteristic reduces current transmission loss and ensures power supply stability | |

Minimum Insulation Resistance | 100 | High insulation resistance suppresses leakage current and improves electrical safety (Test environment: 70℃×1h) | |

Mechanical Performance | Bending Radius (Static/Dynamic) | 4×Cable Outer Diameter / 8×Cable Outer Diameter | Minimum static bending radius (fixed installation) is 4×outer diameter; minimum dynamic bending radius (moving scenarios) is 8×outer diameter, avoiding insulation damage due to excessive bending |

Tensile Strength (Insulation Layer) | ≥12 | Excellent tensile performance of insulation layer, withstanding slight pulling during installation and use | |

Elongation at Break (Insulation Layer) | ≥150 | Insulation layer has high flexibility and is not easy to crack when bent or stretched | |

Environmental Adaptation | Operating Temperature Range | -20 to +80 | Suitable for normal-temperature industrial environments, indoor home appliances, and some outdoor sheltered scenarios; maintains flexibility in low-temperature environments |

Oil Resistance | Mineral Oil Resistant (IPX4 Waterproof) | No significant performance degradation in short-term mineral oil contact; IPX4 waterproof rating, adaptable to splashing water environments (e.g., kitchen appliances, industrial equipment oil pollution scenarios) |

Product Application Scope

1.Industrial Automation Equipment

Robotic systems: Robotic arm joint wiring, sensor connections

CNC machines: Drag chain cables, spindle encoder signal transmission

Conveyor systems: Servo motor power and feedback signal transmission

2.Mobile Machinery & Power Systems

Gantry cranes and hoists: Power and signal transmission for mobile control cabinets

AGV/RGV vehicles: Navigation sensor and drive motor connections

Construction machinery: Hydraulic system sensor wiring

3.Precision Instruments & Measuring Equipment

Medical equipment: High-frequency signal transmission in mobile medical devices

Testing instruments: Sensor data acquisition and control systems

Product Description

Model | CF5.07.12 |

Type | Control Cable |

Brand | igus |

Number of Cores | 12 Cores |

Cross-Sectional Area of Core | 0.75mm² |

Core Material | Copper |

Core Structure | Stranded Structure |

Core Identification | Black Cores (with Numbering) + Ground Wire |

Insulation Material | Polyvinyl Chloride (PVC) |

Insulation Color | Green |

Cable Outer Diameter | 12.5mm |

Rated Voltage | 300/500V |

this cable is mainly used for industrial equipment connection, indoor fixed installation, machine control system wiring, energy chain (cable carrier) matching, and rapid handling systems, providing stable signal and power transmission support for industrial automation-related scenarios.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.