Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

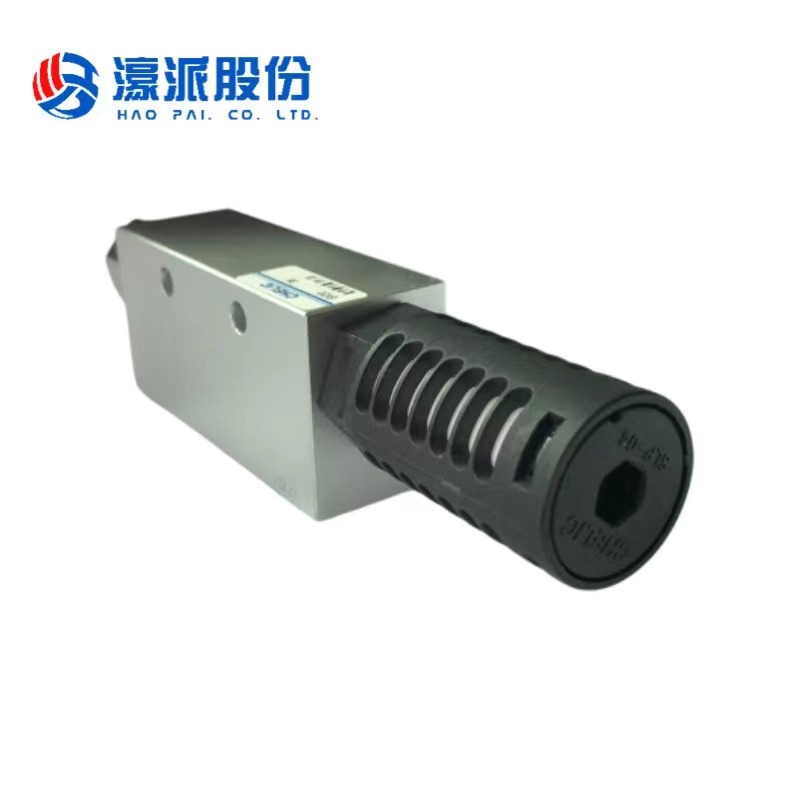

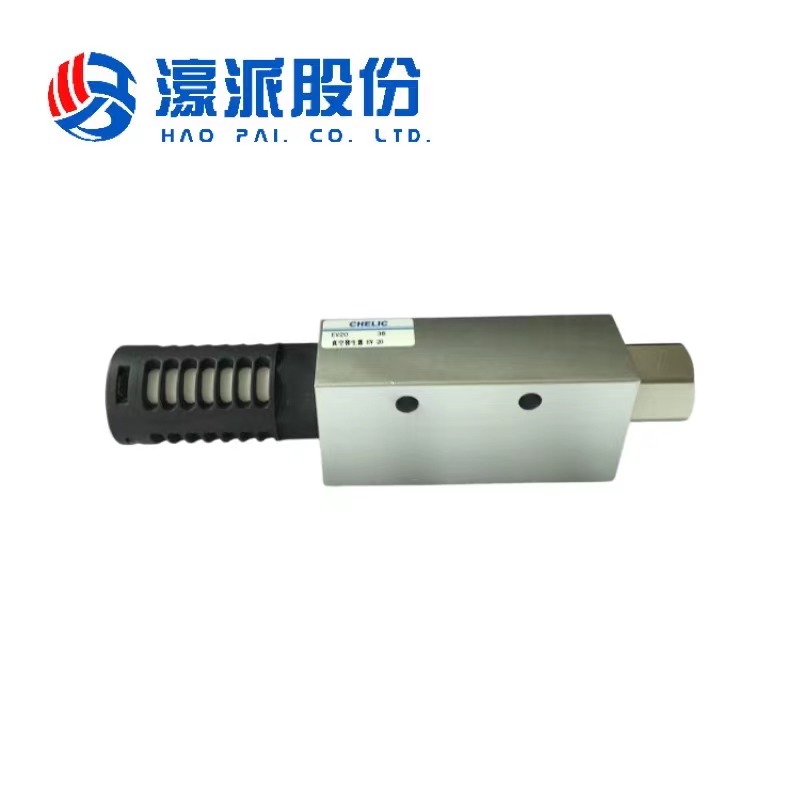

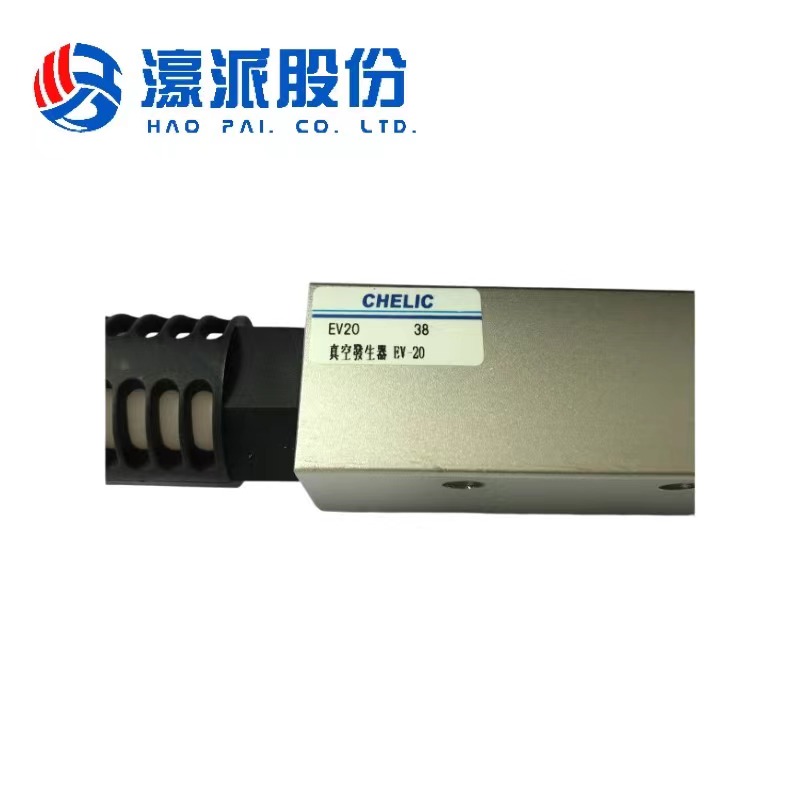

pneumatic vacuum generator-EV-20

- Chelic

- China

- 3-5days

- 30 pcs month

- EV-20

- L45mm W32mm H28mm

Product Advantages and Features

1. Efficient and Convenient Negative Pressure Acquisition:No complex power system is required; it can quickly generate stable negative pressure only by relying on compressed air, meeting the immediate adsorption needs in automated production and significantly shortening the equipment start-up and response time.

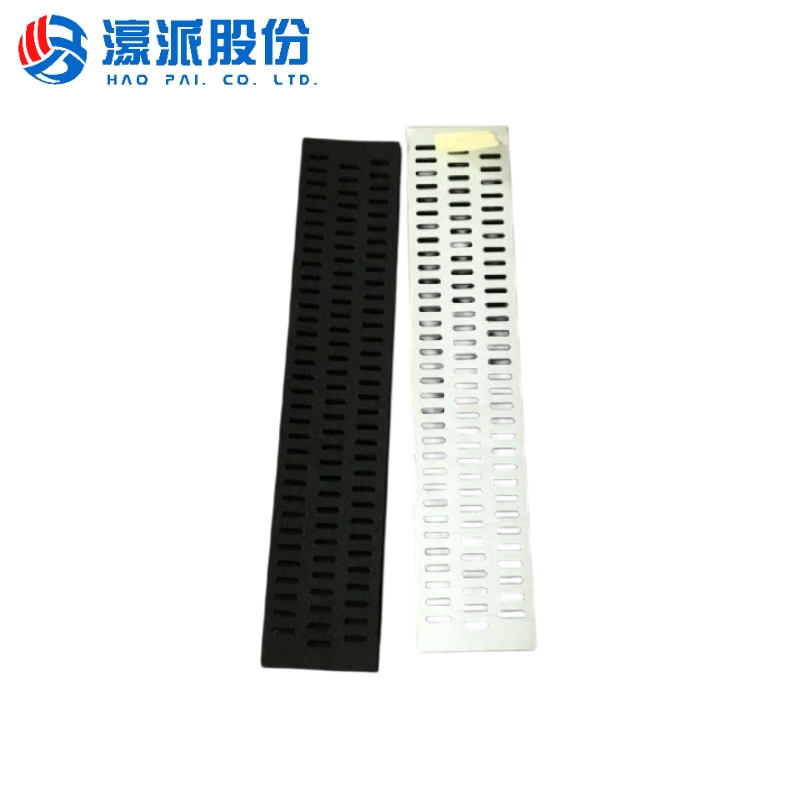

2. Simple Filter Element Replacement Operation:When the filter element is blocked by impurities and causes a decrease in air flow rate, there is no need to disassemble the entire equipment. The dedicated cover can be directly opened to take out the old filter element and replace it with a new one. A single person can complete the maintenance within a few minutes, reducing equipment downtime costs.

3. Diverse Nozzle Specifications:A variety of nozzles with different diameters are available (such as φ1.0mm, φ1.5mm, φ2.0mm, etc.). They can be flexibly matched according to the weight, size of the actual adsorbed materials and the needs of the adsorption surface, adapting to various application scenarios from thin plastic parts to small metal parts.

4. Compact and Durable Structural Design:The body is made of high-strength engineering plastic material, which has both light weight and impact resistance, and can adapt to the complex environment of industrial workshops; at the same time, the overall volume is small, which can be easily integrated into automated equipment or production lines with limited space, saving installation space.

5. Low Energy Consumption and Low Noise:On the premise of generating the same negative pressure, it has lower energy consumption compared with traditional vacuum equipment, effectively reducing the enterprise's production electricity cost; the noise is controlled below 65 decibels during operation, which meets the noise environmental protection standards of industrial workshops and improves the working environment of operators.

Product Technical Parameters

Parameter

| Core Performance | Maximum Negative Pressure: -90kPaAir Consumption: 50-80L/minInput Air Pressure: 0.4-0.6MPa |

Specification Options | Optional Nozzle Diameters: φ1.0mm, φ1.5mm, φ2.0mmInterface Type: G1/8 Thread | |

Environmental Adaptability | Operating Temperature: 0-60℃Protection Class: IP40 | |

Structural Dimensions | External Dimensions (L×W×H): 45mm×32mm×28mmMain Material: ABS Engineering Plastic | |

Safety Protection | Overpressure Protection Threshold: Auto-pressure relief when >0.8MPaFilter Precision: ≥5μm |

Product Application Scope

1. Automated Handling of Solid Wood Panels: Compatible with automatic loading and unloading equipment in woodworking machinery, used for adsorbing solid wood panels (thickness 3-20mm) for transfer between workstations. Its stable negative pressure of -90kPa can firmly adsorb the panels, avoiding slipping or surface scratches during handling; at the same time, it is compatible with the conventional industrial air source of 0.4-0.6MPa, which can be directly connected to the pneumatic system of woodworking machinery without additional power devices.

2. Processing and Fixing of Man-made Boards (e.g., Particleboard, MDF): In woodworking engraving machines, panel saws and other equipment, it is used for adsorbing and fixing man-made boards during processing. The optional nozzle diameters of φ1.0mm-φ2.0mm can be selected according to the panel size to adjust the adsorption force. It not only ensures no displacement of the panel during processing (guaranteeing engraving and cutting accuracy) but also avoids panel deformation caused by excessive adsorption force, adapting to the fine requirements of man-made board processing.

3. Assembly and Positioning of Woodworking Accessories (e.g., Wood Mouldings, Mortise and Tenon Components): For the assembly process of small woodworking accessories, it can cooperate with robotic arms or manual tooling to achieve accessory adsorption and positioning. Its compact structure of 45mm×32mm×28mm can be easily integrated into the narrow workstations of woodworking assembly equipment, especially suitable for scenarios requiring precise positioning such as wood moulding bonding and mortise-tenon component docking, improving assembly efficiency and accuracy.

4. Auxiliary Operations in Woodworking Dust Environment: Next to equipment that generates dust such as woodworking sanders and grinders, it can be used to absorb and clean fine wood chips produced during processing (with a dedicated suction nozzle). The IP40 protection class can effectively prevent wood chips from invading the interior of the equipment, avoiding excessive rapid clogging of the filter element; the overpressure protection function can prevent unstable adsorption force caused by air source fluctuations, ensuring continuous dust cleaning operations.

Product Description

Stable negative pressure of -90kPa | Adsorbs solid wood panels (3-20mm thick) to prevent slipping and scratching during handling |

Optional nozzle diameters (φ1.0mm-φ2.0mm) | Adapts to man-made boards of different sizes; adjusts adsorption force to avoid deformation during processing |

Compact structure (45mm×32mm×28mm) | Integrates into narrow workstations of woodworking equipment; cooperates with robotic arms/tooling for accessory assembly |

IP40 protection class | Blocks wood chips from sanders and grinders from invading the equipment |

Overpressure protection (auto-pressure relief when >0.8MPa) | Copies with air source fluctuations in woodworking workshops to ensure adsorption stability |

Compatible with 0.4-0.6MPa conventional industrial air source | Directly connects to the pneumatic system of woodworking machinery without additional power |

The Chelic EV-20 Vacuum Generator is an efficient auxiliary component in the woodworking machinery field. With stable performance and flexible adaptability, it is an ideal choice for solid wood panel handling, man-made board processing, woodworking accessory assembly, and operations in dusty environments. Its stable negative pressure of -90kPa can meet the adsorption and handling needs of solid wood panels (3-20mm thick), avoiding panel slipping and surface damage during handling. The optional nozzle diameters (φ1.0mm-φ2.0mm) can adjust the adsorption force according to the size of man-made boards, ensuring positioning accuracy during engraving and cutting while preventing panel deformation due to excessive adsorption force. The compact structure (45mm×32mm×28mm) can be easily integrated into narrow workstations of woodworking equipment, matching robotic arms or manual tooling to complete precise assembly of wood mouldings and mortise-tenon components. The IP40 protection class and overpressure protection function enable stable operation in dusty environments (e.g., with sanders and grinders), blocking wood chip intrusion and coping with air source fluctuations, thus ensuring continuous and efficient woodworking production.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.