Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

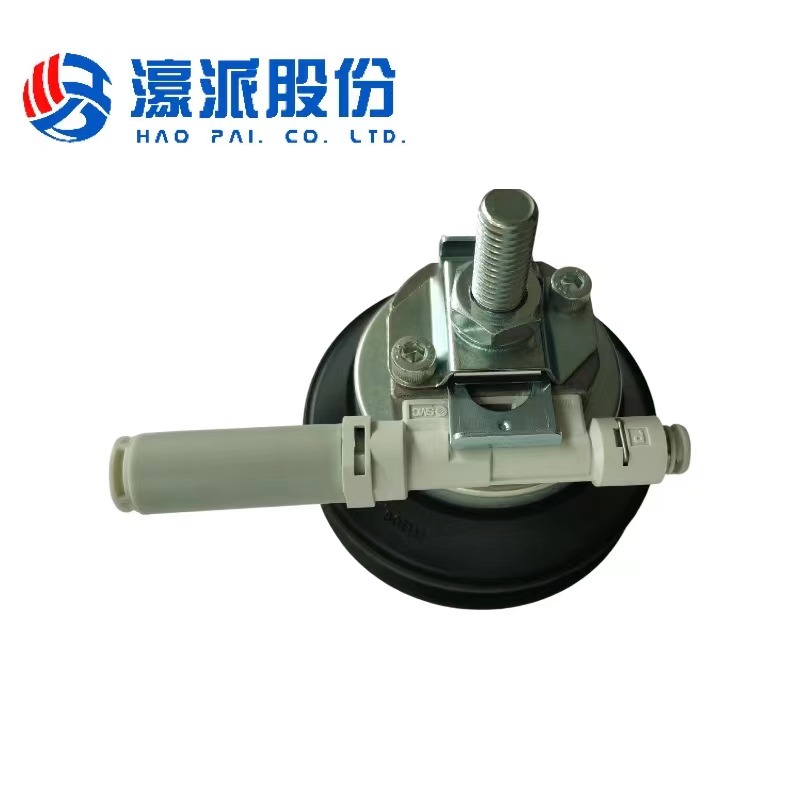

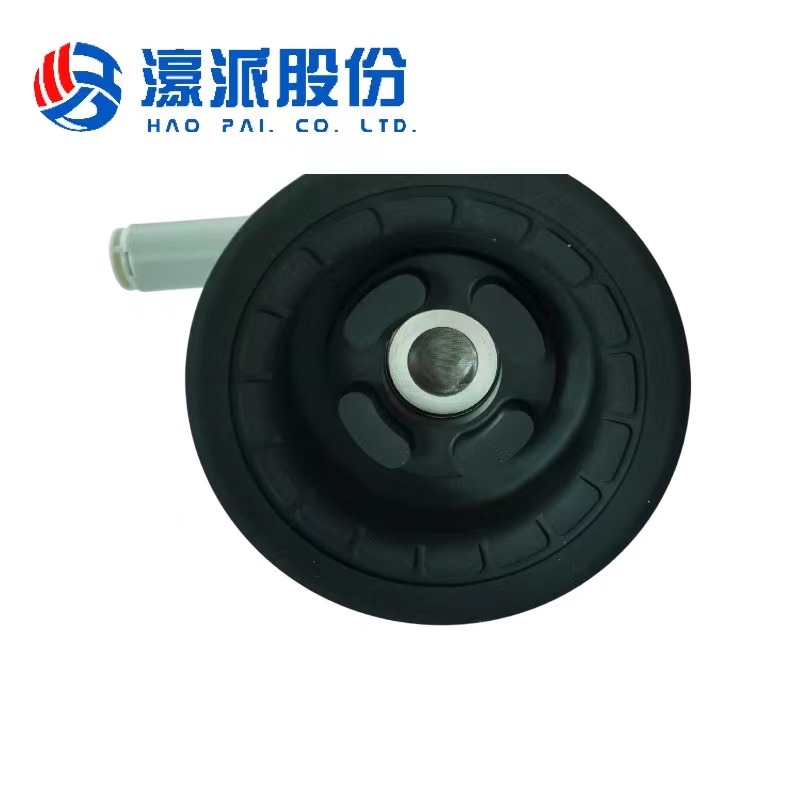

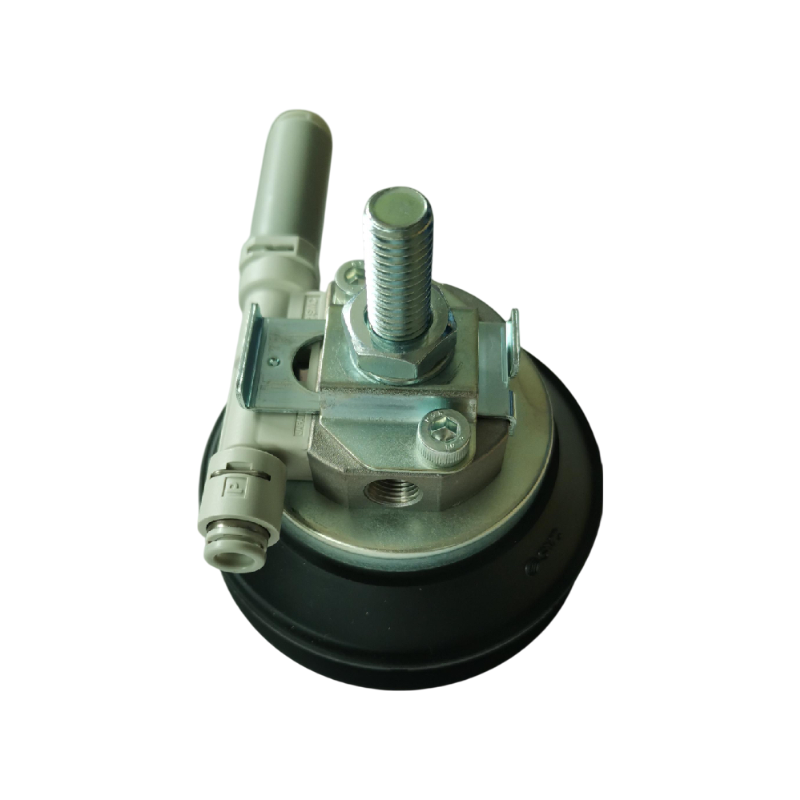

Vacuum Generator-robot arm gripping

- Haopai

- Guangdong, China

- 5-10days

- 30 pcs month

- ZHP80BMNB-10C6S

- 65×42×38 mm

Product Advantages and Features

1. Compact Structure and Flexible Installation: With a small overall volume, it occupies less equipment installation space and is suitable for various complex industrial equipment layouts. Equipped with a variety of standard installation interfaces, it can quickly complete installation and disassembly according to actual working conditions, reducing equipment commissioning time and improving production efficiency.

2. Efficient Vacuum Generation Capacity: Adopting an optimized airflow design, it can quickly extract air and establish a stable high-negative pressure environment in a short time, meeting the rapid vacuum demand in various industrial scenarios. For example, it can quickly adsorb workpieces in automated assembly lines to improve production rhythm.

3. Strong Stability and Durability: The core components are made of high-strength and wear-resistant high-quality materials, which can withstand the working pressure of long-term continuous operation. It also has good corrosion resistance and anti-aging performance, reducing the incidence of equipment failures, prolonging the service life and lowering maintenance costs.

4. Excellent Energy-saving Performance: Compared with traditional vacuum generators, this model significantly reduces compressed air consumption under the same vacuum output effect, effectively lowering the enterprise's energy cost expenditure. At the same time, it reduces carbon emissions during equipment operation, conforming to the concept of green production.

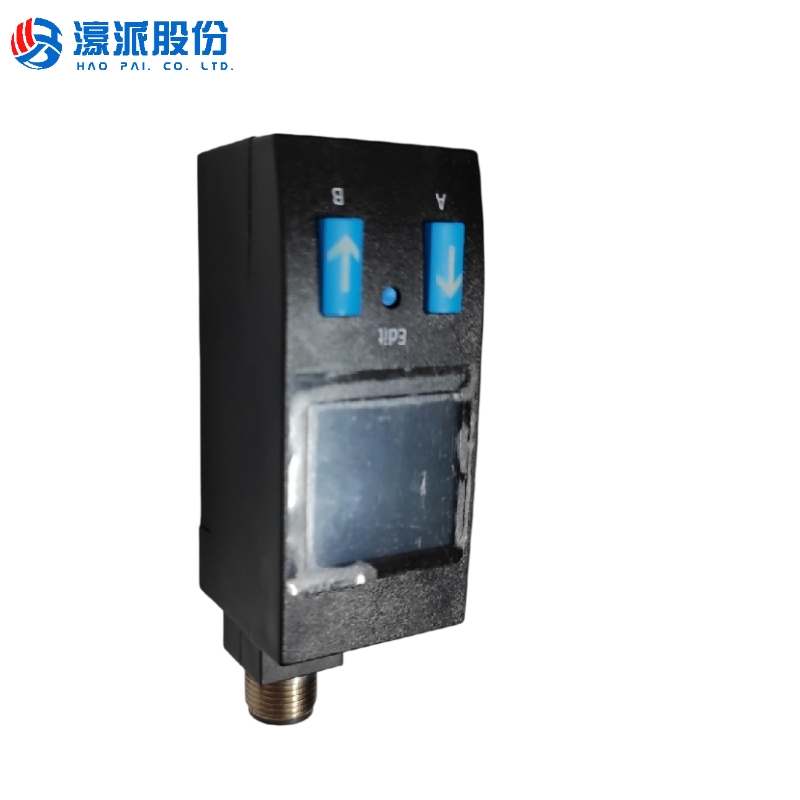

5. Intelligent Monitoring and Protection Functions: Built-in vacuum degree monitoring sensor can feedback the vacuum state in real time, and transmit data to the control system through the signal interface, facilitating operators to grasp the equipment operation status in real time. At the same time, it has overload protection and overpressure protection functions. When the equipment is in abnormal working conditions, it can automatically trigger the protection mechanism to avoid equipment damage and ensure production safety.

Product Technical Parameters

Parameter Category | Parameter Item | Parameter Value |

Vacuum Performance | Maximum Vacuum Level | -92 kPa (Absolute Pressure: 19 kPa) |

Vacuum Response Time | ≤ 0.3 s (From Atmospheric Pressure to -80 kPa) | |

Maximum Air Flow Rate | 80 L/min (ANR) | |

Air Consumption | Compressed Air Supply Pressure | 0.4 - 0.7 MPa |

Average Air Consumption | ≤ 55 L/min (ANR, at 0.5 MPa) | |

Minimum Supply Flow | 30 L/min (ANR) | |

Structure & Installation | Port Size | Inlet: G1/4"; Vacuum Port: G1/4" |

Overall Dimensions (L×W×H) | 65×42×38 mm | |

Mounting Type | Plate Mounting, Bracket Mounting | |

Weight | ≤ 120 g | |

Environment & Protection | Operating Temperature Range | -5 ℃ - 60 ℃ (No Condensation) |

Protection Class | IP40 | |

Vibration Resistance | 10 - 500 Hz, 1.5 G (in XYZ Directions) | |

Electrical Parameters | Sensor Power Supply | 12 - 24 V DC (±10%) |

Output Signal Type | NPN/PNP Dual Output (Optional) | |

Maximum Load Current (Per Output Channel) | 100 mA |

Product Application Scope

1. Industrial Automation Assembly Field: It is compatible with robotic arms and transfer mechanisms in automated production lines, used for adsorbing metal and plastic parts (such as auto parts, home appliance accessories) to achieve precise grabbing, handling and assembly of workpieces. It is especially suitable for assembly line operations with fast rhythm and high precision requirements, such as engine component assembly, core component assembly of printers and other scenarios.

2. Packaging Industry: In the packaging production lines of food, medicine and daily chemical products, it can be used to adsorb various packaging materials, including plastic films, aluminum foils, cartons, metal can lids, etc.

3. Electronics and Semiconductor Manufacturing Field: Aiming at the thin, light and fragile characteristics of electronic components (such as chips, circuit boards, capacitors and resistors), this vacuum generator can provide stable and gentle negative pressure adsorption force for sorting, transferring and testing of components.

4. Automotive Manufacturing and Parts Processing Field: In addition to workpiece handling in the assembly process, it can also be applied to the bonding process of automotive interior parts (such as instrument panels, seat fabrics). It fixes the interior materials through negative pressure adsorption to ensure no bubbles and wrinkles in bonding; at the same time, it is also suitable for the handling and installation of automotive glass, preventing the glass from slipping or breaking during transfer with stable vacuum level.

5. Logistics and Warehouse Automation Field: On the sorting and palletizing equipment of intelligent warehouses, it can be used to adsorb packaging containers such as cartons and plastic turnover boxes to realize automatic grabbing and stacking of goods.

Product Description

Description Category | Description |

Product Positioning | Industrial-grade high-efficiency compact vacuum generator, designed for automated production scenarios, balancing performance and energy-saving needs |

Core Design | Optimized air flow channel + high-strength corrosion-resistant material + intelligent sensing system, enabling rapid vacuum establishment and stable operation |

Core Advantage | High vacuum level, low air consumption, small size, long service life, suitable for complex working conditions in multiple industries |

Applicable Scenarios | Industrial automation, packaging, electronic semiconductors, automotive manufacturing, logistics and warehousing |

Supporting Functions | Real-time vacuum level monitoring, overload/overpressure dual protection, optional NPN/PNP signal output |

The ZHP80BMNB-10C6S vacuum generator is a high-performance device developed for the needs of modern industrial automation, with the core design concept of "high efficiency, energy saving and compactness". In terms of performance, it adopts a specially optimized air flow channel structure, which can establish a negative pressure of -80 kPa from atmospheric pressure within 0.3 seconds, with a maximum vacuum level of up to -92 kPa and an air flow rate of 80 L/min (ANR), which can quickly meet the needs of high-frequency operations such as robotic arm grabbing and material transfer; at the same time, under a supply pressure of 0.5 MPa, the average air consumption is only ≤55 L/min, which is more than 30% energy-saving compared with traditional models, significantly reducing the energy cost of enterprises.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.