Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

Vacuum Suction Cup Block for Homag CNC Machine Center

- Haopai

- Guangdong, China

- 5-10days

- 30 pcs month

- 10.01.12.00770

- 120X50X50 Q

Product Advantages and Features

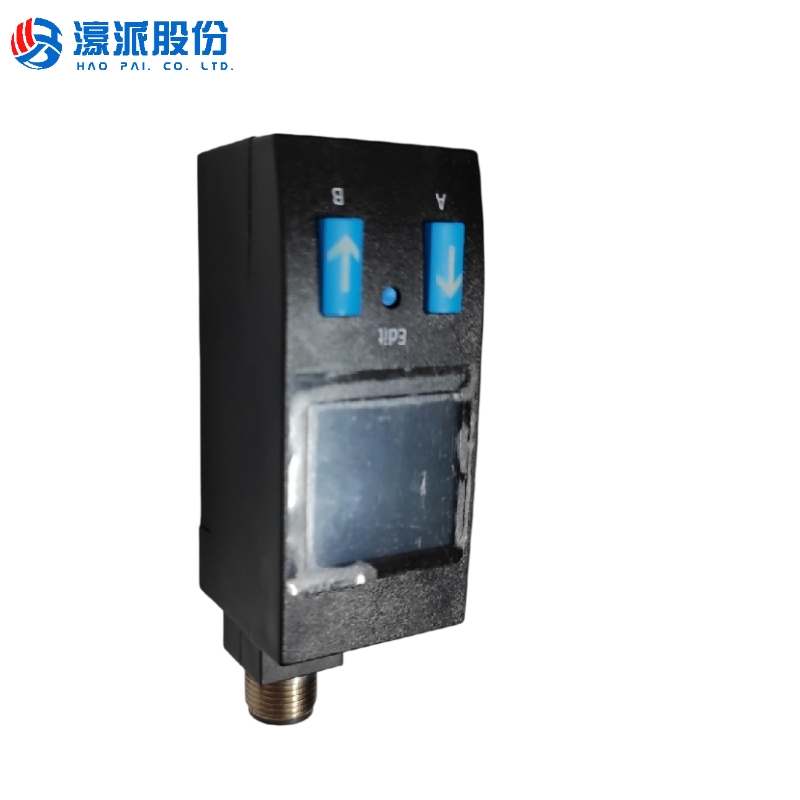

1.Excellent Clamping Flexibility

Eliminates the need for complex, dedicated mechanical jigs. Workpieces of various shapes can be clamped instantly by creating vacuum, making it ideal for high-mix, low-volume flexible manufacturing

2.Full, Unobstructed Access

The workpiece is held flat on the table with its top and sides fully exposed, providing unparalleled tool access. This is perfect for 5-axis machining, 3D engraving, and processing large sheets.

3.Uniformly Distributed Holding Force

The vacuum force is distributed evenly across the entire contact surface. This effectively prevents distortion of thin-walled or delicate parts (e.g., aluminum alloy sheets, carbon fiber panels, plastic) caused by localized clamping pressure, significantly improving machining accuracy and consistency.

4.Extremely High Setup Efficiency

Loading a part and activating the vacuum takes mere seconds. Compared to the tedious setup, alignment, and calibration of traditional fixtures, it drastically reduces changeover time and preparation time, greatly increasing machine utilization.

5.Superior Workpiece Surface Protection

Non-contact clamping means no scratches, marks, or deformation from mechanical force. It is the ideal solution for protecting pre-finished, coated, mirrored, or delicate surfaces (e.g., glass, acrylic, advanced composites).

Product Technical Parameters

Model NO.

10.01.12.00770

Size

Small

Customized

Customized

Type

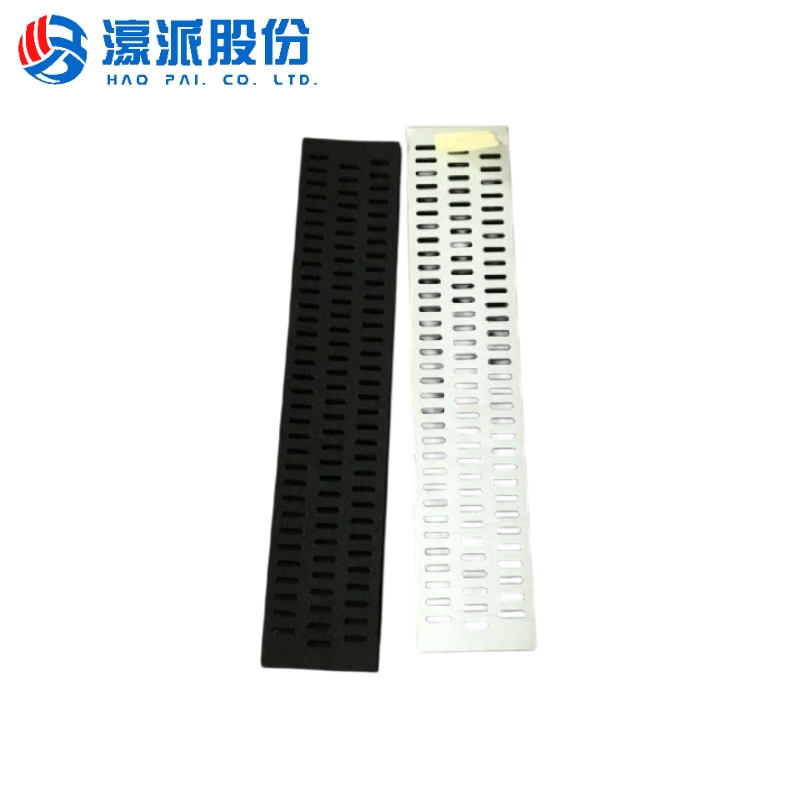

Sucker

Material

PU+Plastic

Condition

New

Characteristics

Long Working Time

Applicable Industries

Woodworking CNC

Transport Package

Carton

Specification

piece

Trademark

Haopai

Origin

Guangdong, China

Packaging & Delivery

Package Size

10.00cm * 10.00cm * 10.00cm

Package Gross Weight

1.000kg

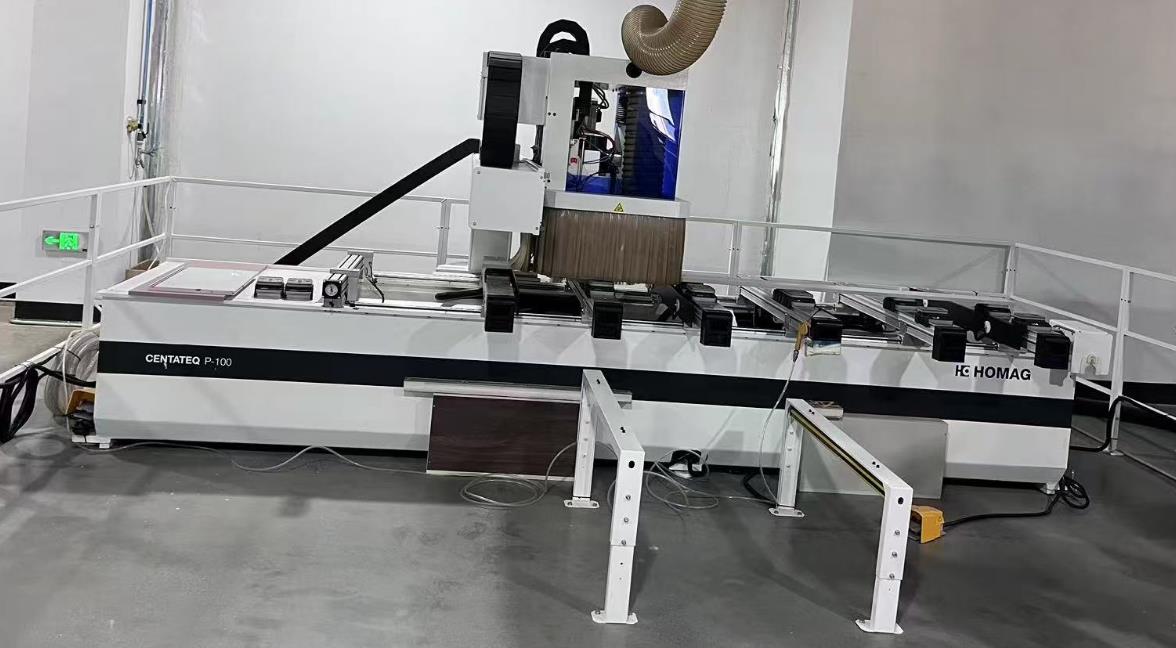

Mechanical Processing Field:

Workpiece Clamping:In CNC machining, it is used to firmly fix workpieces such as sheets, aluminum plates, and copper plates on the working table for machining operations such as cutting, drilling, and milling. For example, CNC milling machines use vacuum fixtures to hold wooden parts to prevent the workpieces from moving during processing, which could damage the products.

2.Automated Assembly:On automated production lines, it serves as the end effector of robots to pick up and transport small parts for assembly operations. It can accurately complete the assembly tasks of electronic components and small mechanical parts.

Logistics and Handling Field:

Heavy Lifting and Transfer:It can grasp and lift heavy objects with flat and regular surfaces. For example, in the logistics industry, it is used for palletizing cardboard boxes, handling packages, and in the machinery and chemical industries for lifting parts and products. It is also used for handling and flipping glass, sheet metal, and large parts in airports, and for large part lifting and transfer in manufacturing. It can replace manual handling and improve work efficiency.

Automated Palletizing:It is used in logistics, warehousing, and ports to automatically grasp and place materials, achieving neat stacking and automated warehouse management.

Food Industry:

1.Food Sorting and Packaging:It is used for sorting, handling, and packaging food. It can grasp food hygienically and prevent food contamination. For example, it can pick up bread, biscuits, and other foods and place them into packaging bags or boxes.

2.Precise Grasping and Stacking:In food production lines, it is used with multi-degree-of-freedom robotic arms to achieve precise grasping and stacking of food products, meeting the industry's requirements for cleanliness and precision.

Electronics Industry:

1.Electronic Component Grasping and Handling:It is used to grasp and handle electronic components such as chips and circuit boards. These components are usually small in size and have high precision requirements. Vacuum suction cups can handle them without causing damage.

2.Electronics Product Assembly and Production:In the production process of electronic products, it is used to hold components such as screens and shells for assembly and processing, improving production efficiency and product quality.

Medical Field:

1.Medical Device Grasping and Handling:It is used to handle medical devices such as surgical instruments and medical consumables. It provides stable and reliable grasping force during the production and use of medical equipment.

2.Laboratory Sample Handling:In laboratories, it is used to handle sample containers such as test tubes and petri dishes, facilitating various experimental operations and analysis.

Glass Industry:

1.Glass Handling and Installation:It can grasp and install various sizes and shapes of glass, such as flat glass, automotive glass, and architectural glass. It enables safe handling and installation of glass, reducing the risk and difficulty of manual operations.

2.Glass Processing and Treatment:In processes such as glass cutting, edging, and coating, it is used to hold glass workpieces to ensure the stability and precision of the processing.

Automotive Manufacturing Field:

1.Automotive Parts Handling and Assembly:It is used to handle automotive parts such as body panels, engine hoods, and doors. It accurately transfers them to the assembly line for assembly operations, improving the automation level and production efficiency of the automotive manufacturing process.

2.Automotive Interior Installation:In the installation process of automotive interiors, such as dashboards, seats, and carpets, it is used to hold and fix these components in place, facilitating installation and fastening operations.

Wood Processing Field:

1.Wood Fixing and Processing:CNC milling machines and other wood processing equipment use vacuum fixtures to hold wooden parts to prevent unexpected movement during cutting and ensure the accuracy and quality of wood processing.

2.Wood Handling and Lifting:With the strong suction force generated by vacuum suction cups, wood such as wooden boards can be firmly grasped and transported to the required positions in the production process. This achieves rapid movement and lifting of wood materials and improves work efficiency.

3.Semiconductor Industry:Ceramic vacuum suction cups are widely used in the manufacturing process of semiconductor wafers such as silicon, sapphire, and gallium arsenide. The suction cups have evenly distributed pores that are interconnected internally. The surface is smooth, fine, and flat after grinding. They can meet the high precision and high cleanliness requirements of semiconductor manufacturing.

Product Description

Package Size

10.00cm * 10.00cm * 10.00cm

Package Gross Weight

1.000kg

In addition to the woodworking industry, vacuum suction cups are widely used in mechanical processing, automated assembly, logistics and handling, food, electronics, medical, glass, automotive manufacturing, and semiconductor industries. They enable the gripping, transporting, positioning, and securing of objects of various materials and shapes. This improves production efficiency and automation levels while reducing labor intensity and risks associated with manual operations.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.