Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

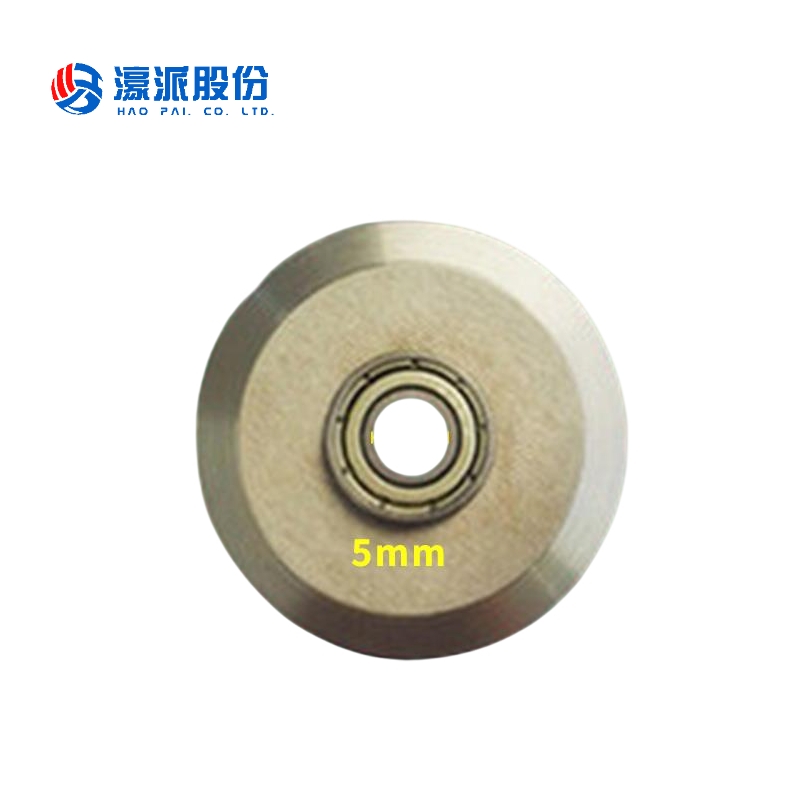

Cutting equipment Bearings(Outer diameter 34, bearing inner diameter 5MM)

- Haopai

- Foshan, China

- 30 days

- two weeks

- Outer diameter 34, bearing inner diameter 5MM

- 3.4cm*0.5cm

Product Advantages and Features

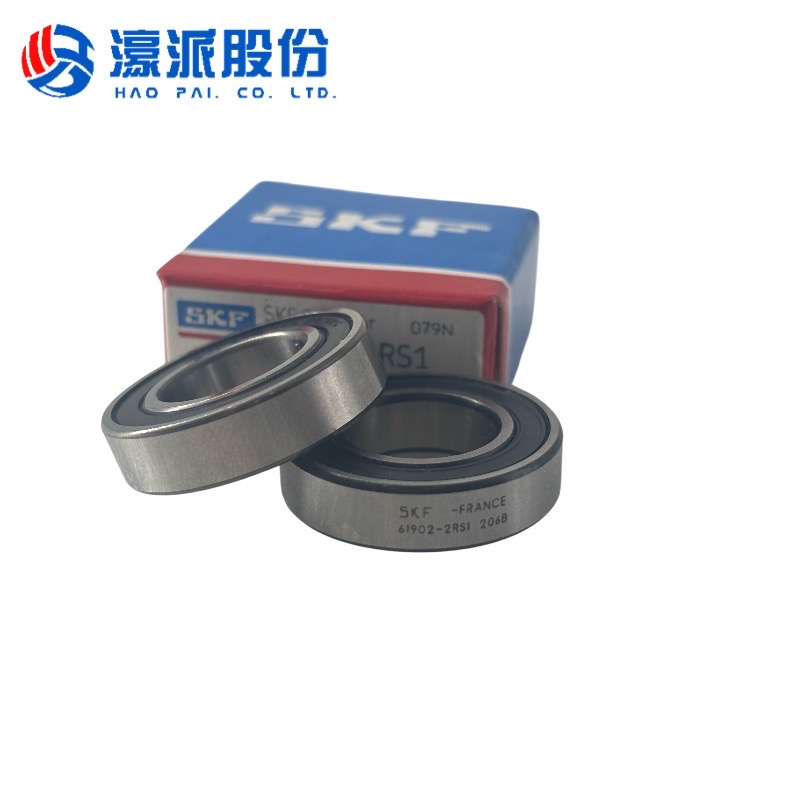

Specific manifestations of advantageous categories.

High rigidity improves axial/radial load-bearing capacity and reduces blade deformation by optimizing contact angles (such as 30 °) and rolling element design.

The high precision level can reach P4, ensuring consistency in machining dimensions and suitable for micrometer level machining.

The high-speed parameters can reach 500000-1000000 min ⁻¹· mm, suitable for high speed milling, drilling and other processes.

Impact resistance: Special heat treatment+coating (such as DLC, CE coating), which remains stable in intermittent cutting or quenched steel processing.

Long lifespan: Sealed lubrication+wear resistant materials, reducing maintenance frequency, and extending lifespan by 3-5 times compared to traditional structures.

Intelligent compatibility: Can integrate sensors to achieve tool condition monitoring and predictive maintenance, supporting Industry 4.0 production lines.

Product Technical Parameters

Brand :HAOPAI

Product origin:FOSHAN

Delivery time :30 days

Supply capacity:two weeks

Model : Outer diameter 34, bearing inner diameter 5MM

Size :3.4cm*0.5cm

Product Application Scope

Application areas, scenario examples, types and characteristics of adapted bearings

Automotive manufacturing: wheel hub bearing seat ring processing, engine cylinder body drilling, gear hard turning CBN blade bearings, high hardness, heat resistance, suitable for HRC60 or above quenched hard steel

Aerospace titanium alloy/nickel based alloy blade milling, composite material drilling, ceramic hybrid bearings, high temperature resistance, low thermal expansion

Mold manufacturing: precision stamping molds, cavity milling of injection molds, high rigidity angular contact bearings, ensuring micrometer level accuracy.

Wind power/energy: large slewing bearings, wind power gearbox bearing hole machining, three row cylindrical roller blade bearings, strong load-bearing capacity, deformation resistance

Tunnel excavation: TBM rolling cutter head rotating support, SKF special rolling cutter bearing, anti vibration, long life, suitable for rock impact

3C Electronics: High speed milling micro angular contact bearings for mobile phone frames and laptop shells, with low noise and high speed.

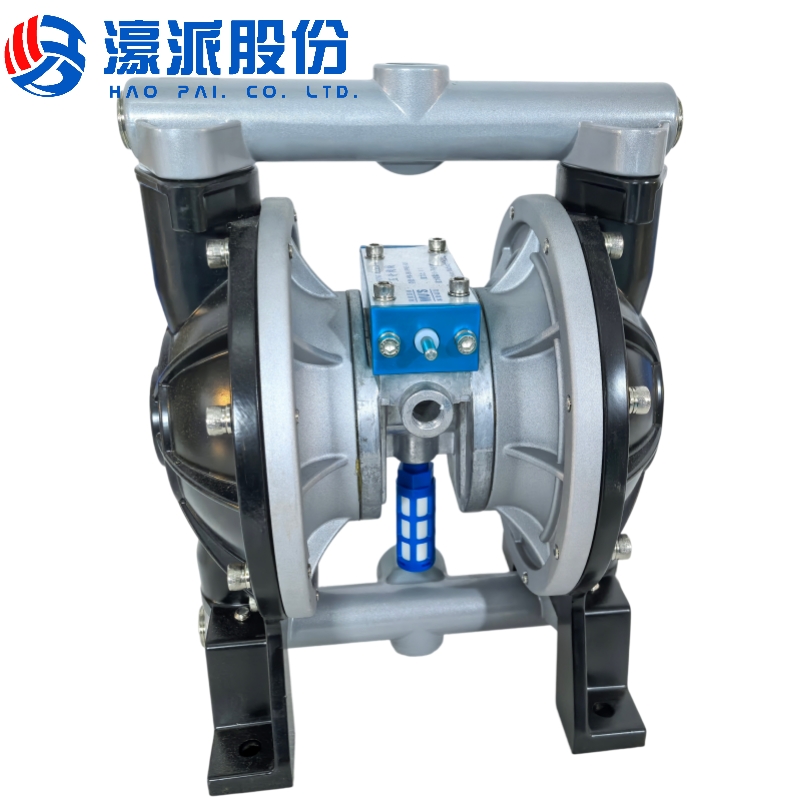

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.