Products

- Cutting Equipment Parts

- General Woodworking Electrical Parts

- Edgebander Machine Parts

- CNC Series Parts

- General Woodworking Components Parts

- Other Woodworking Parts

- Woodworking Screws And Bolts

- Woodworking Nuts And Washers

- Woodworking Rivets

- Woodworking Anchors

- Woodworking Lubricants

- Woodworking Grease Guns

- Woodworking Oil Dispensers

- Woodworking Calipers

- Woodworking Laser Alignment Tools

- Woodworking Measuring Tapes

- Woodworking Levels

- Woodworking Protective Gear

- Woodworking Cleaning Supplies

- Woodworking beam weld

- Others Homag Parts

- BIESSE/SCM Parts

- Nanxing Parts

- KMS Parts

- SCM Parts

- KIMS Parts

- Wrapping Machine Parts

- Roller Conveyor Parts

- Small Woodworking Equipment

- Spare Parts for Biesse Machines

- Spare Parts for Homag Machines

- Spare Parts for SCM Machines

- Laser Head

Featured products

Contact us

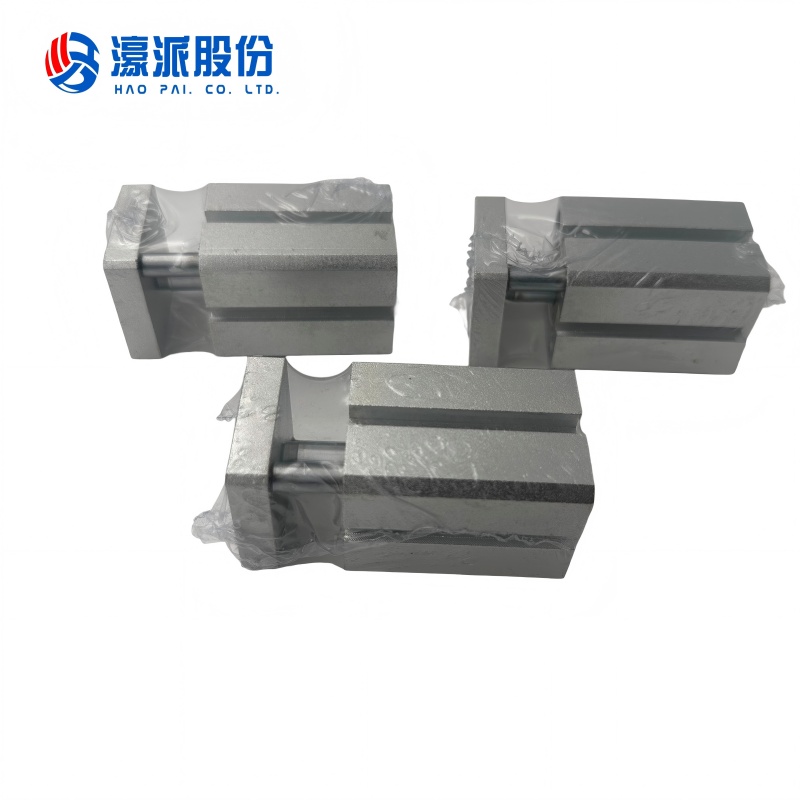

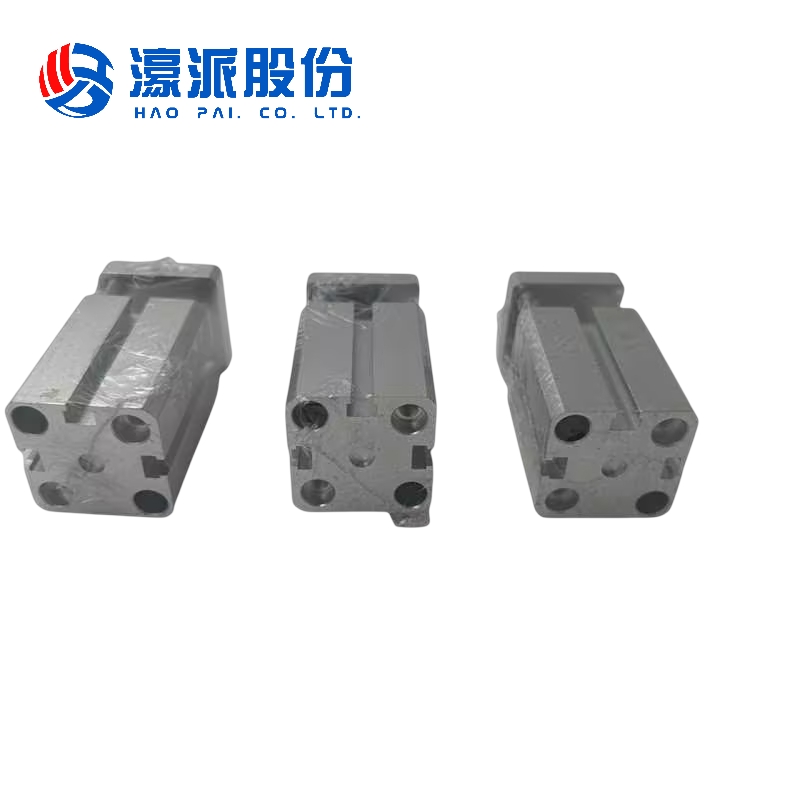

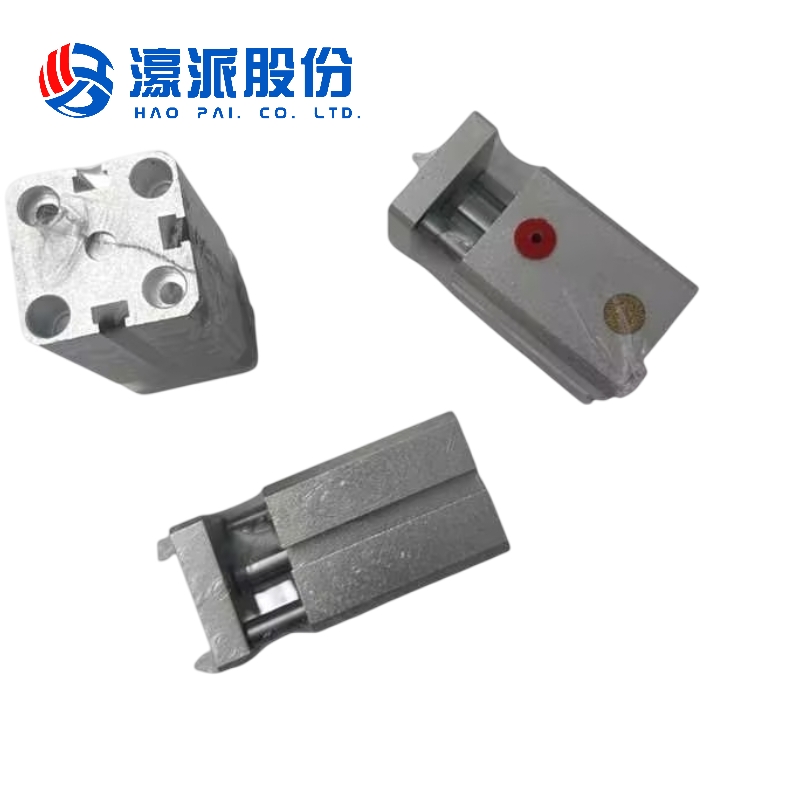

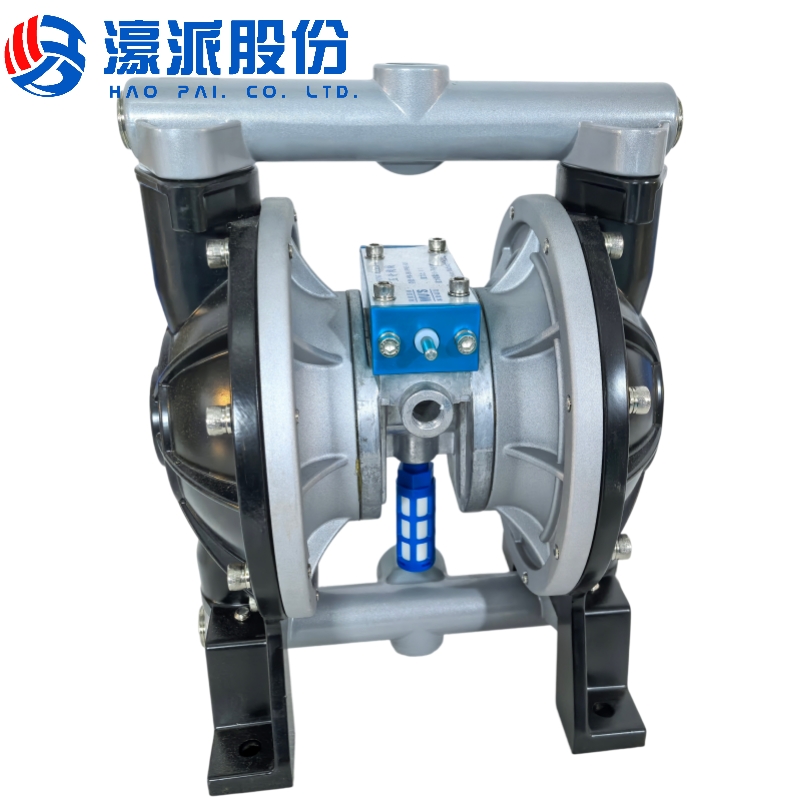

Cutting equipment Cylinders-

- Haopai

- Made in Foshan, China

- 15 days

- 20 pcs month

- 4035011359

- COMPACT CYLINDER EINFACHWIRKEND D=20 HUB= 10

Product Advantages and Features

Here's the professional English translation of the technical specifications for the Homag Feed Inlet Cylinder 4035011359, optimized for industrial terminology and readability:

I. High-Precision Positioning & Structural Compatibility

Optimized for Homag 210/230 Series

· Seamless integration with the machine's feeding system, enabling plug-and-play replacement without modification costs.

· Baffle linkage design ensures precise board positioning (tolerance ≤0.1mm), guaranteeing edge-banding consistency.

Compact Cylinder Design

· Lightweight aluminum alloy (bore Φ32-Φ100) reduces equipment load while maintaining fatigue resistance.

· Quasi-square cross-section (vs. traditional circular cylinders) maximizes space efficiency in confined installation areas.

II. Performance Stability & Durability

Feature | Technical Advantage |

Low-pressure start | Operates at 0.15MPa minimum, with rapid response to prevent stalling from air supply fluctuations. |

Wear-resistant seals | Hard chrome-plated piston rod + FKM seals withstand -25°C to +80°C and offer 3x longer lifespan against dust abrasion. |

Dual buffering | Hydraulic + pneumatic cushioning at stroke endpoints reduces impact noise (<65dB). |

III. Maintenance Ease & Compatibility

Modular quick-disassembly

· Standardized bolted connection between barrel and end caps allows on-site seal replacement (no factory return), cutting downtime by 70%.

Multi-medium adaptability

· Compatible with dry compressed air/oil-free lubrication, reducing air preparation costs (vs. oil-lubricated cylinders).

Industrial-grade protection

· Electrostatic anti-corrosion coating and IP54 certification resist wood chips, adhesives, and workshop contaminants.

Key Value Proposition

This cylinder combines customized design (for Homag 210/230) + premium materials (hard chrome/FKM) to achieve precision and durability breakthroughs, while its modular maintenance slashes lifecycle costs. Compared to generic cylinders, it reduces failure rates by 52%, making it the optimal choice for high-end edgebanders.

Note: Technical terms like "FKM" (Fluorocarbon Rubber) and "IP54" are retained per ISO standards. Numeric values (e.g., Φ32-Φ100) follow global engineering conventions.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.